In the construction industry, choosing the right fastener can make a significant difference in both efficiency and durability. Two commonly used types of nails are coil nails and traditional (or loose/bulk) nails. While both serve similar purposes—joining wood and other materials—they differ significantly in terms of application, performance, and cost-effectiveness. This article provides an in-depth comparison between coil nails and traditional nails, helping contractors, builders, and procurement professionals make informed decisions.

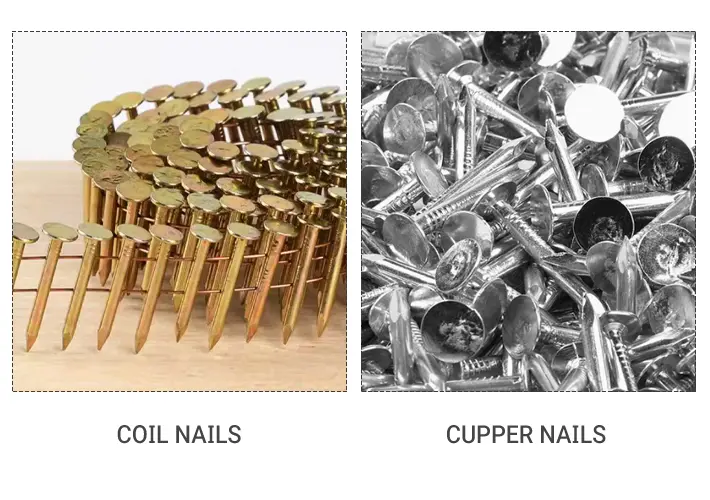

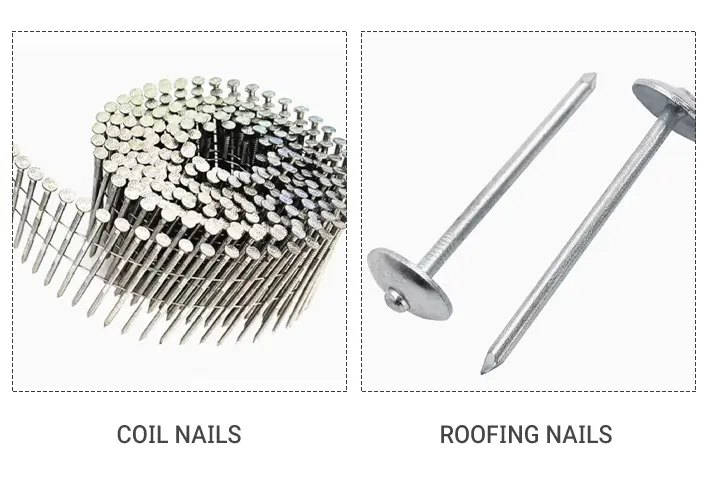

What Are Coil Nails?

Coil nails are nails that are joined together with wire or plastic and wound into a coil shape. They are designed to be used in pneumatic nail guns, especially coil nailers, which automatically feed the nails for rapid and continuous firing.

Key Features:

- Connected in coils (typically 15°-16° angle)

- Comes in lengths from 1″ to 3-1/4″ (25mm to 83mm)

- Made from steel, stainless steel, or galvanized steel

- Often used in framing, fencing, decking, pallet making, siding, and roofing

What Are Traditional Nails?

Traditional nails, also called loose nails, are individual nails not collated together. They are typically driven manually with a hammer or inserted into stick-type nail guns that use straight strips of nails.

Key Features:

- Sold loose or in strips (not coiled)

- Requires more manual handling

- Can be used in manual hammering or in stick nailers

- Commonly used in general-purpose carpentry and DIY projects

Speed and Efficiency

Coil Nails:

- Faster application: Coil nails can be fired rapidly using pneumatic nailers, allowing workers to drive hundreds of nails in a short time.

- Reduced downtime: One coil can hold 200–300 nails, minimizing the need to reload.

- Ideal for large-scale production: In pallet manufacturing or siding installation, coil nails significantly boost productivity.

Traditional Nails:

- Slower application: Manual hammering or less efficient stick nailers limit speed.

- Frequent reloading: Stick nailers typically hold fewer nails (20–40 per strip).

- Higher labor time: Projects take longer, which can increase costs.

Winner: Coil Nails

Tool Compatibility

Coil Nails:

- Requires coil nailers, which are often heavier and more expensive than stick nailers.

- Coil nailers are versatile and support various applications, from roofing to framing.

Traditional Nails:

- Can be used with manual hammers or stick nailers.

- Manual hammers don’t require power or air supply, making them suitable for remote or small jobs.

Best for flexibility: Traditional nails

Best for high output: Coil nails

5. Holding Power and Strength

Coil Nails:

- Available in various shank types: smooth, ring, and screw.

- Ring shank and screw shank coil nails offer superior withdrawal resistance, ideal for structural applications.

- Galvanized and stainless steel options improve corrosion resistance.

Traditional Nails:

- Also available in different shank types, but manual hammering can result in imprecise depth and weaker holding power.

- More dependent on skill for consistent performance.

Winner: Coil Nails (especially ring/screw shank)

Cost Comparison

Coil Nails:

- Higher upfront cost: More expensive than bulk nails due to packaging and collation.

- Requires investment in pneumatic tools and compressors.

- Lower labor cost over time due to increased speed.

Traditional Nails:

- Lower material cost per nail.

- No special equipment required (except hammer).

- Higher labor cost in large-scale projects.

Short-term savings: Traditional nails

Long-term ROI: Coil nails

Waste and Safety

Coil Nails:

- Less wastage: Pre-aligned and consistent feeding reduces bent nails and misfires.

- Safer usage: Pneumatic tools ensure hands are farther from the point of impact.

- Less fatigue: Automation reduces physical strain on workers.

Traditional Nails:

- More likely to bend or be misaligned when hammered manually.

- Higher injury risk from mis-hits or flying nails.

- Increased fatigue, especially on larger projects.

Winner: Coil Nails (especially for safety and reduced fatigue)

Application Scenarios

Material and Finish Options

Coil Nails:

- Galvanized, stainless steel, aluminum options

- Smooth, ring, or screw shank

- Bright finish, electro-galvanized, hot-dip galvanized

Traditional Nails:

- Common nail, box nail, brad nail, casing nail

- Similar finish options but fewer industrial-grade varieties

Industrial Versatility: Coil Nails

Storage and Transportation

Coil Nails:

- Packaged in compact coils, saving space

- Better for bulk shipment to job sites or export

- Less chance of damage in transit

Traditional Nails:

- Require more space for the same number of nails

- Can spill or get lost easily

Logistics-friendly: Coil Nails

Environmental and Sustainability Considerations

While both types of nails are made primarily from steel, coil nails often come with collation wires or plastic, which can create waste. However, some manufacturers now use recyclable plastic tape or paper collation to reduce environmental impact.

Traditional nails have less packaging waste, but the inefficiencies in labor and potential for more material waste (due to bent nails or breakage) can offset the environmental benefit.

More eco-friendly option depends on specific job scale and waste handling

Summary Comparison Table

Conclusion: Which Should You Choose?

Choose Coil Nails if:

- You’re working on large-scale construction projects

- You need speed and consistency

- You want to reduce labor time and fatigue

- You’re producing items in volume (e.g., pallets, siding, roofing)

Choose Traditional Nails if:

- You’re doing small-scale or DIY projects

- Budget is a primary concern

- You work in remote areas with limited power/compressor access

- You prefer manual control

Final Thoughts for B2B Buyers

For construction companies, nail distributors, and wholesalers, investing in coil nail systems is a smart move for large-scale projects and industrial applications. They not only enhance productivity but also offer greater consistency and safety.

If you’re a nail supplier or importer, it’s essential to offer both types, but emphasize the advantages of coil nails for your commercial clients. Look for manufacturers who provide:

- CE/ISO-certified nails

- Custom packaging

- Consistent quality (low jam rate, rust resistance)

- Competitive FOB and container pricing

Looking for a reliable coil nail manufacturer from China?

Choose a supplier with strong factory strength, fast delivery times, and export experience in construction markets like the USA, Europe, and Southeast Asia.