IBR roof sheeting has become one of the most commonly used roofing materials in residential, commercial, and industrial construction projects around the world. Known for its strength, durability, affordability, and ease of installation, IBR sheeting is often the go-to choice for builders, homeowners, and contractors alike. But when it comes to actual costs, many buyers want to know: How much does IBR roof sheeting cost? What factors influence the price? In this comprehensive guide, we’ll break down everything you need to know about IBR roof sheeting prices in 2026 — from material costs and labour to factors that can raise or lower the price.

What Is IBR Roof Sheeting?

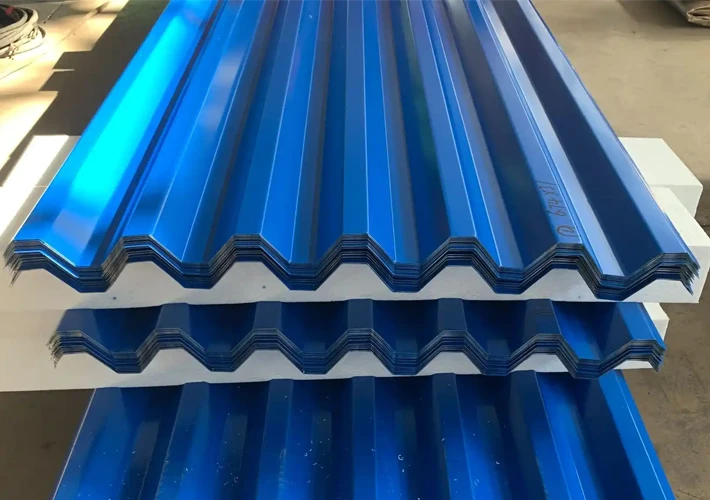

IBR stands for Inverted Box Rib, a profile shape for metal roof sheets characterized by deep ribs that enhance structural strength and water dispersion. IBR sheeting is typically made from:

- Galvanized steel

- Galvalume steel

- Pre-painted steel (Color Coated)

- Aluminium and other metal alloys

The profile is often 686 mm or similar cover width and is favoured for its rigidity and ability to span long distances with fewer supports compared to plain corrugated sheets.

Typical IBR Roof Sheeting Prices

2.1 Prices by Material and Thickness

IBR roof sheet prices can vary significantly based on material, thickness (gauge), coating, and location. The most frequently cited price ranges globally are:

| Material / Specification | Approx. Price per linear meter (USD) |

|---|---|

| Galvanized Steel (0.4 mm) | $8–$12 |

| PVDF-Coated Steel (0.5 mm) | $12–$18 |

| Aluminum (0.5 mm) | $20–$30 |

These prices are typical for export markets or general market references. For larger thicknesses or premium coatings (e.g., marine-grade or PVDF finishes), prices tend to increase proportionally.

2.2 IBR Prices in Regional Markets

South Africa Example

In South Africa, where IBR is widely used, prices are often listed per sheet or per linear meter:

| Specification | Approx. Price (per sheet / per meter) |

|---|---|

| Standard Galvanized IBR | R100 – R420 per sheet (varies by size) |

| Chromadek / Color Coated IBR | R505 – R1020 per sheet (premium options) |

Other local price lists show:

| Gauge | Price per linear meter (Incl. VAT) |

|---|---|

| 0.47 mm Zincalume® AZ150 | R125–R135 |

| 0.53 mm Colorplus AZ150 | R175–R190 |

| 0.54 mm Colorbond™ Ultra AZ200 | R215–R220 |

These regional prices illustrate how coating type, thickness, and supplier influence final pricing.

What Determines the Cost of IBR Roof Sheeting?

3.1 Material and Coating Types

The material composition of IBR sheeting has one of the most significant impacts on cost:

- Galvanized Steel: Generally the most affordable option, suitable for most roofing needs.

- Galvalume (Zn-Al Alloy): Higher corrosion resistance, ideal for coastal or humid regions, and priced higher than plain galvanized.

- Color Coated / PVDF: Pre-painted steel with long-life paint systems (such as PVDF) commands a premium because of durability and aesthetic appeal.

- Aluminum: More expensive but lighter and superior corrosion resistance.

3.2 Thickness (Gauge)

IBR sheet thickness is typically measured in millimetres (mm). Thicker sheets (e.g., 0.5 mm, 0.6 mm, 0.8 mm) cost more than lighter 0.3 mm or 0.4 mm gauges due to higher steel content, increased strength, and longer lifespan.

3.3 Sheet Length and Coverage

IBR sheets are manufactured in long lengths (e.g., 3.0 m, 4.5 m, 6.0 m), and the price is often proportional to length:

- Longer sheets reduce overlap and labour, saving money on large roofs.

- The covered width (usually ~686 mm) determines how many sheets are needed for a given roof area.

Estimating the number of sheets required is essential to calculate overall cost — Number of sheets = Roof length ÷ Sheet cover width.

3.4 Regional Market Conditions and Shipping

Local steel prices fluctuate with global commodity trends. For instance, steel prices surged during pandemic supply chain disruptions and then stabilized, still remaining above pre-pandemic levels in many regions.

Transport and shipping costs can also add significantly to total cost, especially for shipped or imported sheets.

Labour and Installation Costs

Material cost is only part of the budget. Installation and labour costs vary by region and roof complexity:

4.1 Installation per m²

In markets like South Africa, installation rates for IBR roofing are often quoted per square metre:

| Material Cost (Typical) | Labour Cost | Total per m² |

|---|---|---|

| R85 – R125 (IBR sheet) | R80 – R120 | R165 – R245 |

Professional installation is recommended for correct overlap, sealing, and flashings to prevent leaks and ensure long life.

4.2 Additional Components

Additional cost elements include:

- Flashings and ridge caps

- Fasteners (weather-resistant screws and washers)

- Insulation or sarking underlay

- Gutter and downpipe work

These extras can account for 10–20 % or more of total project costs.

How Much Does a Full IBR Roof Project Cost?

To estimate the total cost of an IBR roof installation, consider the following elements:

5.1 Material Estimate

Roof Area Calculation

Example: Roof area = 100 m²

Sheets Required

Using a 0.686 m cover width, you’d need ~146 sheets of 4.5 m length (specific calculation depends on pitch and waste factor).

Material Cost

If standard galvanized sheets cost $10 per linear meter, then:

- Sheet length × price = 4.5 m × $10 = $45 per sheet

- Total sheets × cost = 146 × $45 = $6,570

Extras + Fasteners

Add flashings, screws, ridge caps = ~$500–$1,200 (depending on roof complexity)

5.2 Installation Labour

Using typical labour rates (adjusted for your region and currency), you might add:

- ~ $80–$120 per m² for labour

- For 100 m²: approx. $8,000–$12,000 total labour

5.3 Overall Project

Thus, a complete IBR roofing project (materials + labour + extras) for a 100 m² roof may range:

$15,000 – $20,000 depending on materials, location, labour rates, and roof complexity.

(This is a general estimate — actual figures will vary by region and market conditions.)

IBR Roof Sheeting Cost Comparison with Other Materials

When comparing IBR with other roofing solutions:

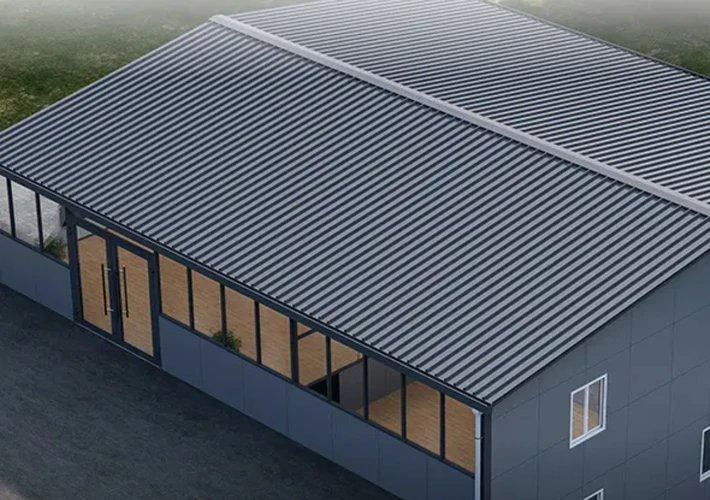

- IBR vs Traditional Corrugated Sheets: IBR often costs slightly more per metre than simple corrugated sheets due to enhanced profile strength — but this makes it more efficient (less supporting timber needed).

- IBR vs Tiles / Asphalt: Ceramic tiles and asphalt shingles are generally more expensive in terms of material and structure weight, making IBR better value for metal roofing.

- IBR vs Premium Metal Systems (e.g., Standing Seam): Premium metal roofing systems cost more due to specialised profiles and installation techniques.

Tips to Save on IBR Roof Sheeting Costs

7.1 Buy in Bulk

Bulk purchases often attract discounts, sometimes 10–15 % lower per unit price.

7.2 Choose Appropriate Thickness

Selecting a thickness that matches your climate and structural needs avoids unnecessary costs while ensuring durability.

7.3 Use Local Suppliers

Local sourcing reduces freight charges and delays, particularly for larger projects.

7.4 Get Multiple Quotes

For both materials and installation, compare at least three quotes to ensure competitive pricing.

Conclusion

Understanding IBR roof sheeting prices is crucial for accurate budgeting in any construction project. Costs are influenced by:

- Material type and thickness

- Coating and corrosion resistance

- Regional market conditions

- Installation and labour charges

- Additional components required for a full roof system

business owner budgeting for construction, this guide gives you a detailed breakdown to help make informed pricing decisions.

IBR sheeting remains a cost-effective, durable, and widely available roofing solution — and knowing what affects its price helps you get the best value for your investment.