Introduction: Why PPGI vs PPGL Matters for Global Buyers

In the global steel and construction materials market, pre-painted steel coils play a crucial role in roofing, wall cladding, appliances, prefabricated buildings, and industrial manufacturing. Among them, PPGI (Pre-Painted Galvanized Iron) coils and PPGL (Pre-Painted Galvalume Steel) coils are the two most widely used products.

For overseas buyers, project contractors, distributors, and importers, a common and very practical question arises:

PPGI vs PPGL coils – which one is better for my project?

The answer is not simply “which is better”, but rather:

- Which one is more suitable

- Which one offers better cost-performance

- Which one performs better under specific climate and application conditions

As a China-based steel coil manufacturer and exporter, we work with clients from Southeast Asia, the Middle East, Africa, South America, Europe, and North America. We frequently see misunderstandings about PPGI and PPGL, especially regarding corrosion resistance, lifespan, price differences, and application scenarios.

What Is PPGI Coil?

Definition of PPGI

PPGI (Pre-Painted Galvanized Iron) is a type of color-coated steel coil produced by applying an organic coating (paint) on the surface of hot-dip galvanized steel.

In simple terms:

- Base steel → cold-rolled steel

- Metal coating → zinc (Zn)

- Surface coating → primer + topcoat (PE, SMP, HDP, PVDF, etc.)

Structure of PPGI Coil

A standard PPGI coil typically consists of:

Cold-rolled steel substrate

Zinc coating (usually Z40–Z275)

Chemical pretreatment

Primer coating

Topcoat (color paint)

Optional back coating

Key Characteristics of PPGI

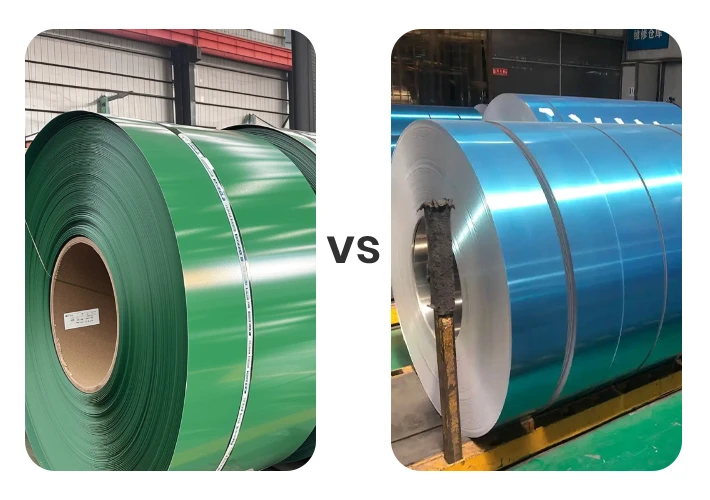

- Good corrosion protection in normal environments

- Strong adhesion between zinc layer and paint

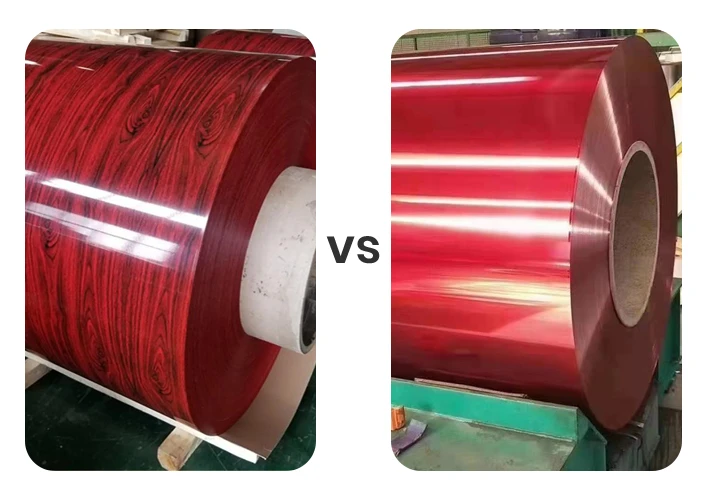

- Smooth surface and rich color options

- Mature production process and stable quality

- Competitive price compared to PPGL

Common Applications of PPGI

PPGI coils are widely used in:

- Residential and commercial roofing

- Wall panels and cladding

- Steel structure buildings

- Ceiling systems

- Garage doors

- Home appliances (refrigerators, washing machines)

- Light industrial buildings

What Is PPGL Coil?

Definition of PPGL

PPGL (Pre-Painted Galvalume Steel) is also a color-coated steel coil, but the key difference lies in the metallic coating.

Instead of pure zinc, PPGL uses galvalume coating, which is typically:

- 55% Aluminum (Al)

- 43.4% Zinc (Zn)

- 1.6% Silicon (Si)

Structure of PPGL Coil

PPGL coil structure includes:

Cold-rolled steel substrate

Al-Zn-Si alloy coating (AZ30–AZ150)

Chemical treatment

Primer coating

Topcoat (high-performance paint)

Back coating

Key Characteristics of PPGL

- Excellent corrosion resistance

- Superior heat reflectivity

- Longer service life in harsh environments

- Strong edge corrosion protection

- Better performance in coastal and industrial areas

Common Applications of PPGL

PPGL coils are commonly used for:

- Industrial roofing systems

- Large-span steel structures

- Coastal buildings

- High-end prefabricated houses

- Warehouses and logistics centers

- Power plants and chemical facilities

- Agricultural buildings

PPGI vs PPGL: Core Differences Explained

To truly understand PPGI vs PPGL, we must compare them from material composition, performance, cost, and real-world usage.

1.Metal Coating Difference

| Item | PPGI | PPGL |

|---|---|---|

| Metal coating | Zinc (Zn) | 55% Al + 43.4% Zn + 1.6% Si |

| Standard | Z40–Z275 | AZ30–AZ150 |

| Protection mechanism | Sacrificial protection | Barrier + sacrificial protection |

Key takeaway:

PPGL’s aluminum-rich coating provides better long-term corrosion resistance, especially in aggressive environments.

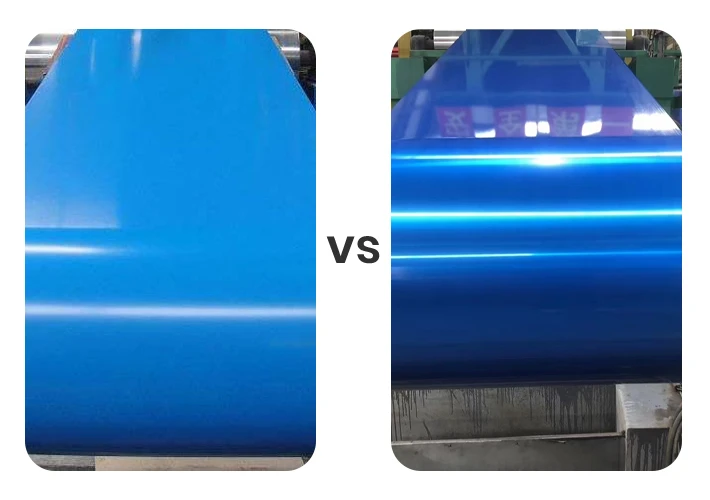

2.Corrosion Resistance Comparison

Corrosion resistance is the most important difference between PPGI and PPGL.

- PPGI relies mainly on zinc’s sacrificial protection.

- PPGL combines aluminum’s barrier protection with zinc’s sacrificial effect.

In salt spray tests and outdoor exposure:

- PPGL can last 2–4 times longer than PPGI in coastal or industrial environments.

- In normal urban or inland areas, PPGI performance is usually sufficient.

Practical example:

In coastal Southeast Asia or the Middle East:

- PPGI lifespan: ~10–15 years

- PPGL lifespan: ~20–30 years

3.Heat Resistance and Reflectivity

PPGL coils have higher aluminum content, which provides:

- Better heat reflectivity

- Lower roof surface temperature

- Reduced thermal expansion

This makes PPGL more suitable for:

- Hot climates

- Factories with high indoor temperature requirements

- Energy-efficient buildings

PPGI performs well in standard environments but has lower reflectivity compared to PPGL.

4.Edge Corrosion Performance

When steel coils are cut, the exposed edges become vulnerable.

- PPGI: Zinc offers sacrificial protection, but once consumed, corrosion can spread.

- PPGL: Aluminum forms a stable oxide film that significantly slows edge corrosion.

For roofing sheets with many cut edges, PPGL clearly performs better.

5.Paint System Compatibility

Both PPGI and PPGL can use similar paint systems:

- PE (Polyester)

- SMP (Silicone Modified Polyester)

- HDP

- PVDF

However:

- PPGL is more commonly paired with high-end coatings like PVDF.

- PPGL + PVDF is often specified in long-life architectural projects.

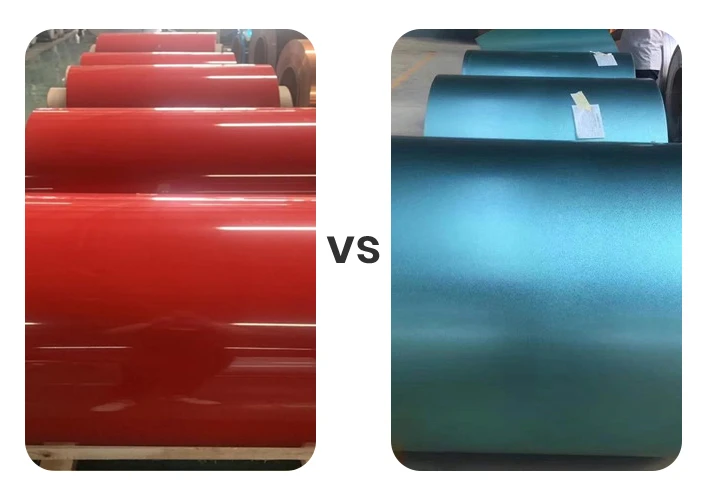

PPGI vs PPGL: Cost Comparison and ROI Analysis

Initial Material Cost

Generally speaking:

PPGI is cheaper than PPGL

PPGL costs 10%–30% more, depending on:

- Coating weight

- Paint system

- Steel thickness

- Market aluminum prices

Total Lifecycle Cost

While PPGL has a higher upfront price:

- Longer lifespan

- Lower maintenance cost

- Fewer replacements

For long-term projects, PPGL often delivers better ROI.

Which Is More Cost-Effective?

| Project Type | Recommended |

|---|---|

| Short-term buildings | PPGI |

| Budget-sensitive projects | PPGI |

| Coastal areas | PPGL |

| Industrial zones | PPGL |

| Long-life roofing | PPGL |

| Warehouses | Depends on environment |

Application-Based Selection Guide

Roofing Sheets

- Inland residential roofing → PPGI

- Coastal or industrial roofing → PPGL

Wall Cladding

- Decorative façade → PPGI or PPGL

- High-end architecture → PPGL

Prefabricated Buildings

- Temporary structures → PPGI

- Permanent modular buildings → PPGL

Appliances and Furniture

- Indoor use → PPGI

- Outdoor exposure → PPGL

PPGI vs PPGL in Different Climates

Tropical Regions

- High humidity

- Frequent rain

- Salt air in coastal zones

Recommendation: PPGL

Desert and Hot Areas

- High temperature

- Strong UV exposure

Recommendation: PPGL with SMP or PVDF coating

Mild Inland Areas

- Moderate climate

- Low corrosion risk

Recommendation: PPGI

Manufacturing Standards and Quality Control

As a professional PPGI and PPGL coil manufacturer in China, quality control is critical.

Key standards include:

- ASTM A755

- EN 10169

- JIS G3322

- GB/T 12754

Critical quality factors:

- Coating thickness consistency

- Paint adhesion

- Color stability

- Gloss control

- T-bend and impact resistance

Reliable factories offer:

- Full MTC (Mill Test Certificate)

- SGS / BV inspection

- Custom specifications

How to Choose a Reliable PPGI & PPGL Supplier in China

When sourcing from China, buyers should focus on:

Production line capability

Raw material source (Baosteel, Shougang, etc.)

Export experience

Coating and color customization

MOQ flexibility

Stable delivery time

A professional supplier should not push PPGL or PPGI blindly, but help you choose the right material for your market.

Future Trends: PPGI and PPGL Market Outlook

- Growing demand for PPGL in infrastructure projects

- Increasing use of high-durability coatings

- Demand for longer warranties

- Green building standards favoring long-life materials

PPGI will remain dominant in cost-sensitive markets, while PPGL demand will grow steadily in industrial and coastal regions.

Conclusion: PPGI vs PPGL – Which One Should You Choose?

There is no absolute winner between PPGI and PPGL.

Choose PPGI if:

- Your project is inland

- Budget is critical

- Lifespan requirement is moderate

Choose PPGL if:

- Your project is coastal or industrial

- Long-term durability matters

- You want lower maintenance costs

As a China-based PPGI & PPGL coil manufacturer and exporter, we recommend selecting materials based on environment, application, and total lifecycle cost, not just initial price.

If you choose correctly, both PPGI and PPGL can deliver excellent performance and commercial value.