Introduction

Plastic expansion screws, also known as plastic wall plugs, plastic anchors, or nylon expansion anchors, are among the most widely used fastening solutions in the global construction, renovation, and installation industries. From residential housing and commercial buildings to hotels, retail spaces, and prefabricated structures, plastic expansion screws play a critical role in securing fixtures to walls, ceilings, and floors.

Compared with metal anchors or chemical fasteners, plastic expansion screws are lightweight, cost-effective, corrosion-resistant, and easy to install. These features make them particularly popular in drywall systems, masonry walls, concrete substrates, and hollow wall structures. As global construction projects increasingly focus on efficiency, labor cost reduction, and standardized installation systems, the demand for plastic expansion screws continues to grow.

However, despite their widespread use, plastic expansion screws are not a universal solution. Their performance depends heavily on substrate type, load requirements, environmental conditions, and correct installation practices. For international buyers, contractors, distributors, and project developers, understanding both the advantages and disadvantages of plastic expansion screws is essential for selecting the right fastening solution and avoiding costly failures on site.

This article provides a comprehensive, professional analysis of plastic expansion screws, covering their structure, working principles, advantages, limitations, application scenarios, material types, and selection guidelines. It is designed to help global B2B buyers make informed purchasing decisions and optimize fastening performance in real construction projects.

What Are Plastic Expansion Screws?

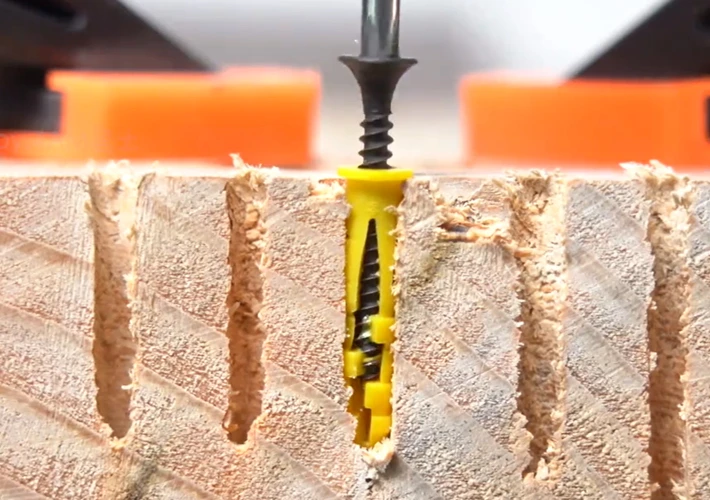

Plastic expansion screws consist of two main components:

1.A plastic expansion plug (anchor)

2.A corresponding screw (usually steel, stainless steel, or galvanized)

When the screw is driven into the plastic plug, the plug expands outward, creating friction and mechanical interlock with the surrounding substrate. This expansion action provides holding power and load resistance.

Plastic expansion screws are typically used in materials such as:

- Concrete

- Solid brick

- Hollow brick

- Cement block

- Plasterboard

- Lightweight concrete

- Stone and masonry walls

Depending on design, plastic anchors may feature ribs, wings, anti-rotation fins, or split expansion zones to improve grip and prevent spinning during installation.

Common Materials Used in Plastic Expansion Screws

The performance of plastic expansion screws depends significantly on the material used for the anchor body. The most common materials include:

Nylon (PA)

Nylon expansion plugs are the most popular choice for professional construction use. They offer:

- High tensile strength

- Excellent elasticity

- Good aging resistance

- Stable performance under temperature changes

Nylon anchors are suitable for both indoor and outdoor applications and are widely used in European and North American markets.

Polyethylene (PE)

PE plastic anchors are more economical and flexible. They are commonly used for:

- Light-duty applications

- Indoor installations

- Temporary fixings

However, PE anchors have lower load capacity and poorer aging resistance compared to nylon.

Polypropylene (PP)

PP anchors offer moderate strength and chemical resistance. They are often used in cost-sensitive projects but are less common in high-load or professional construction environments.

Advantages of Plastic Expansion Screws

Cost-Effectiveness and Economic Efficiency

One of the most significant advantages of plastic expansion screws is their cost-effectiveness. Compared with metal anchors, chemical anchors, or mechanical expansion bolts, plastic expansion screws have a much lower unit cost. This makes them ideal for large-scale projects where thousands or even millions of fasteners are required.

For importers, wholesalers, and project contractors, plastic expansion screws provide:

- Lower procurement costs

- Reduced transportation expenses due to lightweight packaging

- Competitive pricing for mass distribution

In price-sensitive markets such as Southeast Asia, Africa, the Middle East, and parts of Latin America, plastic expansion screws are often the first choice for standard wall-mounting applications.

Easy and Fast Installation

Plastic expansion screws are designed for simple and efficient installation. The process typically involves:

Drilling a hole

Inserting the plastic anchor

Driving in the screw

No specialized tools, chemicals, or curing time are required. This simplicity significantly reduces installation time and labor costs, which is especially important in overseas construction projects where labor expenses are high.

For projects such as:

- Hotel interior fit-outs

- Retail store renovations

- Prefabricated housing

- Modular construction systems

Plastic expansion screws help contractors complete installations faster while maintaining acceptable performance standards.

Lightweight and Convenient for Logistics

Plastic expansion screws are extremely lightweight compared with metal fastening systems. This offers several logistical advantages:

- Lower shipping costs

- Easier handling on construction sites

- Reduced worker fatigue during installation

For international trade, lightweight fasteners also help reduce container weight and optimize cargo loading, which is particularly valuable for exporters and distributors shipping to distant markets.

Corrosion Resistance

Unlike metal anchors, plastic expansion screws are naturally resistant to corrosion. They do not rust, oxidize, or degrade when exposed to moisture, humidity, or certain chemicals.

This makes plastic expansion screws suitable for:

- Bathrooms and kitchens

- Coastal areas with high humidity

- Basements and utility rooms

- Indoor wet environments

When paired with stainless steel or galvanized screws, the overall fastening system can achieve good durability even in challenging conditions.

Electrical Insulation Properties

Plastic expansion screws are non-conductive, which makes them safer for installations near electrical wiring, cable trays, or electrical boxes. This characteristic reduces the risk of short circuits or electrical hazards during installation.

In commercial buildings, data centers, hotels, and residential electrical installations, plastic anchors are often preferred for mounting:

- Cable clips

- Junction boxes

- Electrical conduits

- Switch panels

Reduced Risk of Substrate Damage

Compared with heavy-duty metal anchors, plastic expansion screws exert lower expansion stress on the surrounding material. This reduces the risk of:

- Cracking masonry

- Spalling concrete

- Damaging fragile substrates

For lightweight walls, hollow bricks, or older buildings with weaker structures, plastic expansion screws provide a safer and more forgiving fastening solution.

Wide Range of Sizes and Designs

Plastic expansion screws are available in a wide variety of:

- Diameters

- Lengths

- Expansion structures

- Specialized designs for hollow walls or drywall

This flexibility allows buyers to match the fastener precisely to the application, improving performance and reducing material waste.

Environmentally Friendly Compared with Metal Anchors

While plastic is not biodegradable, plastic expansion screws generally require less energy to manufacture than metal anchors. Their lightweight nature also reduces transportation-related carbon emissions.

Many manufacturers now offer:

- Recyclable nylon materials

- Low-VOC production processes

- Compliance with international environmental standards

This makes plastic expansion screws a more environmentally responsible choice in certain construction scenarios.

Disadvantages of Plastic Expansion Screws

Limited Load-Bearing Capacity

The most notable disadvantage of plastic expansion screws is their limited load-bearing capacity compared with metal anchors or chemical fasteners. Plastic anchors are generally suitable for light to medium loads but are not designed for heavy structural applications.

They are not recommended for:

- Heavy machinery

- Structural steel components

- Load-bearing frames

- Safety-critical installations

Using plastic expansion screws beyond their load limits can result in pull-out failure, loosening, or long-term instability.

Performance Depends Heavily on Substrate Quality

Plastic expansion screws rely on friction and mechanical expansion, which means their holding power is highly dependent on the quality of the substrate.

In weak or brittle materials such as:

- Old brickwork

- Crumbling concrete

- Low-density blocks

The anchor may not expand properly, leading to poor fixation strength.

In such cases, alternative solutions such as chemical anchors or metal expansion bolts may be more appropriate.

Sensitivity to Temperature Extremes

Plastic materials can be affected by extreme temperatures. In very cold environments, plastic anchors may become brittle, while in high-temperature conditions, they may soften or deform.

This limitation makes standard plastic expansion screws less suitable for:

- Industrial furnaces

- High-temperature mechanical rooms

- Outdoor installations in extreme climates

Special high-performance nylon anchors can mitigate this issue but usually come at a higher cost.

Aging and UV Degradation

Over time, plastic expansion screws can degrade due to:

- UV exposure

- Long-term heat

- Chemical exposure

In outdoor applications without UV-resistant formulations, plastic anchors may lose strength, become brittle, or crack. This is a critical consideration for façade installations, outdoor signage, or exterior cable management.

Lower Fire Resistance

Plastic expansion screws generally have lower fire resistance compared with metal anchors. In the event of a fire, plastic anchors may melt or lose holding strength quickly.

For fire-rated walls, ceilings, or safety-critical installations, plastic expansion screws may not meet building code requirements unless specifically certified.

Installation Errors Can Easily Reduce Performance

Although plastic expansion screws are easy to install, incorrect installation can significantly reduce their effectiveness. Common issues include:

- Oversized or undersized drill holes

- Incorrect anchor length

- Incompatible screw types

- Over-tightening, causing anchor deformation

Proper installation guidelines and quality control are essential, especially in large-scale projects.

Typical Applications of Plastic Expansion Screws

Plastic expansion screws are commonly used in:

- Interior wall mounting

- Furniture installation

- Light fixtures and lamps

- Curtain rails and blinds

- Bathroom accessories

- Cable management systems

- HVAC accessories

- Decorative panels and wall cladding

In hotel projects, residential developments, and commercial interiors, plastic expansion screws are widely used due to their balance of performance, cost, and ease of use.

Plastic Expansion Screws vs Metal Anchors

Compared with metal anchors, plastic expansion screws offer:

- Lower cost

- Easier installation

- Better corrosion resistance

- Reduced substrate stress

However, metal anchors provide:

- Higher load capacity

- Better fire resistance

- Longer service life in extreme conditions

The choice between plastic and metal anchors should be based on load requirements, safety standards, and environmental conditions.

How to Choose the Right Plastic Expansion Screws

When selecting plastic expansion screws for a project, buyers should consider:

- Substrate material and density

- Required load capacity

- Indoor or outdoor environment

- Temperature range

- Fire rating requirements

- Installation method

- Compliance with local building codes

Professional manufacturers usually provide detailed technical data sheets, load test results, and application guidelines to support proper selection.

Quality Control and Manufacturing Considerations

For international buyers, product quality is a critical factor. High-quality plastic expansion screws should offer:

- Consistent material composition

- Precise dimensions

- Strong expansion performance

- Reliable packaging for export

Reputable manufacturers conduct:

- Tensile strength testing

- Aging resistance testing

- Load capacity verification

- Batch quality inspections

Working directly with experienced factories ensures stable supply, consistent quality, and competitive pricing for global markets.

Conclusion

Plastic expansion screws are an essential fastening solution in modern construction, offering significant advantages in terms of cost, installation efficiency, corrosion resistance, and versatility. They are especially suitable for light to medium-duty applications in residential, commercial, and hospitality projects.

However, they also have clear limitations, including lower load capacity, sensitivity to substrate quality, aging, and fire performance. Understanding these advantages and disadvantages is crucial for selecting the right fastening system and ensuring long-term safety and performance.

For global B2B buyers, contractors, and distributors, choosing high-quality plastic expansion screws from reliable manufacturers, combined with correct application and installation practices, can deliver excellent value and performance across a wide range of construction projects.

By carefully matching the fastener to the project requirements, plastic expansion screws can remain a dependable, efficient, and cost-effective solution in the global building materials market.