Introduction

PVC tarpaulin has become one of the most widely used industrial and commercial materials across the world. From truck covers, tents, and canopies to advertising billboards, agriculture, construction, and emergency relief, PVC tarpaulin is valued for its waterproof performance, high tensile strength, UV resistance, and cost-effectiveness.

For global importers, China remains the largest manufacturing hub for PVC tarpaulin, supplying more than 70% of global demand thanks to competitive pricing, mature production technology, and strong export capability.

This guide provides a complete and professional overview for international wholesalers, distributors, engineering contractors, and brand owners who want to import PVC tarpaulin from China. You will learn about material classification, production process, specifications, applications, quality inspection standards, thickness/weight comparison, market pricing trends, and how to choose a reliable manufacturer in China.

What Is PVC Tarpaulin?

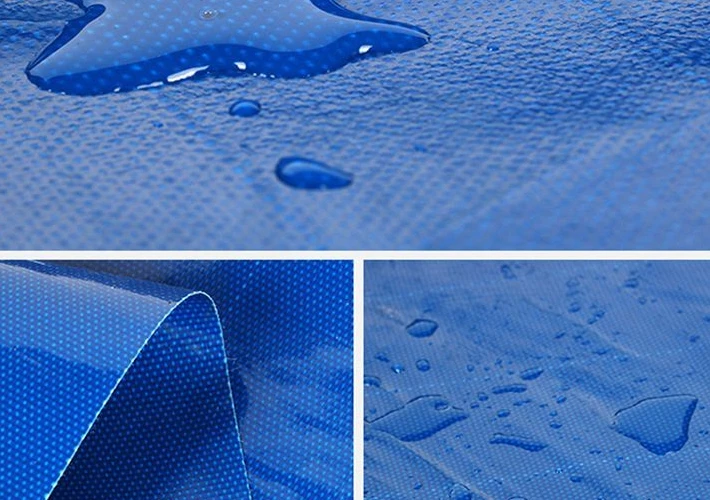

PVC tarpaulin is a polyvinyl chloride-coated fabric reinforced with a high-strength polyester base cloth. It is produced by coating liquid PVC paste onto woven polyester fabric, followed by heat setting and surface treatment.

Its key advantages include:

- 100% waterproof

- High tensile and tear strength

- UV and weather resistance

- Fire retardant (B1, B2 grades available)

- Anti-mildew

- Cold-resistant (up to −30°C with cold-resistant additives)

- Cost-effective for large-scale outdoor use

PVC tarpaulin typically has a lifespan of 3–10 years depending on thickness, coating quality, surface treatment, and outdoor exposure.

Main Types of PVC Tarpaulin

Different applications require different technical standards. Chinese factories mainly supply the following categories:

1.Laminated PVC Tarpaulin

Made by laminating PVC film with polyester fabric.

- Economical

- Lightweight

- Suitable for temporary covers, advertising banners, agriculture, packaging

Common weights: 300–600 gsm

2.Coated PVC Tarpaulin (Knife-Coated)

A high-performance industrial-grade material.

- Strong bonding

- Long service life

- High tensile and tear strength

- Suitable for trucks, canopies, tents, and industrial structures

Weights: 650–1500 gsm

3.PVC Coated Canvas (Poly Cotton Base)

- Good breathability

- Better for long-term storage covers, camping tents

4.Fire-Retardant PVC Tarpaulin

Meets B1/B2, NFPA701 standards.

Ideal for event tents, industrial warehouses.

5.Transparent PVC Tarpaulin

Crystal-clear PVC film.

- Greenhouses

- Sides of tents

- Industrial curtains

6.Anti-UV & Outdoor Grade Tarpaulin

Special UV stabilizers added for sunlight-heavy regions such as the Middle East, Africa, and Australia.

7.Cold-Resistant PVC Tarpaulin

Maintains flexibility under −20°C to −40°C.

Common Specifications & Technical Data

When importing PVC tarpaulin from China, pay attention to the following specifications:

1.Weight (GSM)

The most important factor.

Typical GSM ranges:

| Application | Weight |

|---|---|

| Light covers | 300–450 gsm |

| Advertising banners | 440–510 gsm |

| Truck covers | 550–680 gsm |

| Heavy-duty tents | 700–900 gsm |

| Industrial structures | 900–1500 gsm |

2.Thickness

Usually between 0.25–1.5 mm.

3.Base Fabric (Polyester)

Density affects strength.

Common base cloth specifications:

- 500D×500D, 18×18

- 1000D×1000D, 9×9

- 1000D×1000D, 12×12

- 1300D×1300D

Higher denier = stronger tarpaulin.

4.Tensile & Tear Strength

Industrial-grade tarpaulin should meet:

- Tensile strength: ≥ 1500 N/5cm

- Tear strength: ≥ 180 N

5.Coating

- Single-side coated

- Double-side coated

- Knife-coated (superior)

6.Surface Treatment

- Acrylic coating

- Anti-UV coating

- Anti-slip

- Anti-mildew

- Glossy/Matte finish

7.Width

Typical widths:

1.02 m

1.37 m

1.83 m

2.5 m

3.2 m

4.0 m

Custom max width: 5.1 m

8.Standard Colors

Blue, green, orange, red, white, black, grey, yellow.

Special colors can be customized.

Main Applications of PVC Tarpaulin

PVC tarpaulin is widely used in industrial, commercial, and municipal fields. Major applications include:

1.Truck & Trailer Covers

- Waterproof, sun-resistant

- Knife-coated tarpaulin is the mainstream for long-distance logistics

2.Event Tents & Canopies

- High durability

- Fire retardant

- Long outdoor lifespan

3.Agriculture

- Grain storage

- Hay bale covers

- Greenhouse sides

- Pond liners

4.Construction

- Scaffolding tarps

- Temporary shelters

- Dust control covers

5.Industrial Curtains

- Warehouse partitions

- Welding curtains

- Sound insulation barriers

6.Advertising & Printing

- Banner material

- Billboard

- Flex banner (frontlit, backlit)

7.Marine & Outdoor

- Boat covers

- Outdoor furniture covers

- Camping tents

8.Emergency Relief

- Refugee tents

- Makeshift medical stations

- Disaster shelters

PVC tarpaulin’s versatility is a major reason it is heavily purchased by global B2B buyers.

The Production Process in Chinese PVC Tarpaulin Factories

Understanding how PVC tarpaulin is produced helps you evaluate factory quality.

1.Raw Material Preparation

- PVC resin powder

- Plasticizers

- Stabilizers

- Polyester base fabric

- UV additives

- Color pigments

2.Mixing & Formulation

Factories blend liquid PVC paste (PVC + additives).

Better formulas = stronger coating.

3.Coating or Laminating

Two main technologies:

Lamination

- Hot melt process

- Used for economic tarpaulin

Knife Coating

- Multiple coating layers

- Best bonding strength

- Suitable for heavy-duty applications

4.Heat Setting

Ensures stability and reduces shrinkage.

5.Surface Treatment

- Acrylic

- Anti-UV

- Anti-fungal

- Anti-slip

6.Cutting & Welding

Hot air welding

High-frequency welding

Used to make tarpaulin sheets, tent components, truck covers, etc.

7.Quality Control Inspection

Includes testing:

- GSM

- Tensile strength

- Tear resistance

- Waterproof pressure

- Color fastness

- Adhesion strength

- Width tolerance

How to Choose a Reliable PVC Tarpaulin Manufacturer in China

China has hundreds of PVC tarpaulin factories, but quality varies. Evaluate suppliers based on these standards:

1.Production Capacity

A reliable factory should have:

- Knife coating machines

- Warp knitting machines

- Calendar lines

- Welding equipment

- 24-hour QC monitoring

Monthly capacity of 500–1000 tons is standard for a medium-large manufacturer.

2.Export Experience

Professional manufacturers export to:

- Europe

- Middle East

- Africa

- South America

- Southeast Asia

Check their export certificates and customer base.

3.Quality Certificates

Look for:

- ISO 9001

- REACH

- RoHS

- Fire-retardant (B1/B2)

- SGS test reports

4.Customization Capability

A strong factory can offer:

- Custom colors

- Custom GSM

- Width up to 5.1m

- Anti-UV / Anti-mold enhancements

- Printed logo or patterns

5.In-house QC Laboratory

The best factories have testing machines for:

- Tensile

- Tear

- Thickness

- Adhesion

- Flame retardancy

6.Price Transparency

Avoid factories that only give prices without providing specification sheets.

7.Good Communication

Professional suppliers respond quickly and offer detailed technical parameters.

China PVC Tarpaulin Price (2024–2025 Market Guide)

Prices vary due to raw materials, GSM, coating technology, and surface treatment. The following prices represent average FOB China rates:

| Type | Weight | Price (FOB China) |

|---|---|---|

| Laminated tarpaulin | 300–450 gsm | $0.85–$1.25 / m² |

| Standard coated tarpaulin | 500–650 gsm | $1.45–$2.10 / m² |

| Heavy-duty coated tarpaulin | 700–900 gsm | $2.30–$3.50 / m² |

| Fire-retardant tarpaulin | 650–900 gsm | +$0.30–$0.50 / m² |

| Transparent PVC | 0.3–1.0 mm | $1.50–$4.00 / m² |

Price Trend

- PVC resin price fluctuated significantly in 2023–2024 due to oil price volatility.

- 2025 is expected to stabilize due to increased supply capacity in China.

- Coated tarpaulin prices have increased by 3–5% YoY due to rising labor and energy costs.

Tips for Importing PVC Tarpaulin from China

To reduce risk and ensure consistent product quality, follow these recommendations:

1.Request Detailed Specification Sheets

Ask for:

- GSM tolerance

- Base fabric density

- Tensile & tear strength

- Coating type

- Surface treatment

- Color codes

- Roll width & length

2.Request Samples First

Compare samples with the actual production quality.

3.Conduct Factory Audit (On-site or Video)

Check production lines and QC system.

4.Confirm Packaging Requirements

Typical packing:

- Rolls

- Kraft paper

- Pallet packing

- Shipping marks customization

5.Use 40HQ Containers for Better Freight Cost

PVC tarpaulin is heavy; optimized quantity lowers freight costs.

6.Ask for Test Reports

Especially for:

- UV resistance

- Flame-retardant

- Environmental compliance

7.Use Stable Payment Terms

Common payment terms:

- T/T 30% deposit + 70% before loading

- LC at sight

Why Choose a China Factory for PVC Tarpaulin?

China dominates the global PVC tarpaulin manufacturing market for good reasons:

1.Mature Production Technology

Over 20 years of knife coating and laminated production experience.

2.Competitive Price

Lower raw material and labor costs reduce overall cost.

3.Large Export Volume

Factories are very familiar with international standards.

4.Complete Supply Chain

Everything from PVC resin to polyester fabric is produced domestically.

5.Strong R&D Capability

Factories continuously upgrade UV formulas and develop higher-strength tarpaulin.

6.Flexible Customization

China factories can customize:

- GSM

- Logo printing

- Width

- Color

- Fire-retardant grade

Conclusion

PVC tarpaulin is one of the most essential materials in logistics, construction, agriculture, advertising, and outdoor industries. China, as the world’s leading PVC tarpaulin manufacturer, provides global buyers with competitive prices, stable quality, and strong production capacity.

This guide has covered:

- Types of PVC tarpaulin

- Technical specifications

- Applications

- Manufacturing process

- Quality standards

- Prices

- Tips for importing

- Key advantages of choosing a Chinese factory

Whether you are a distributor, wholesaler, brand owner, or project contractor, sourcing from a reliable Chinese PVC tarpaulin manufacturer will help you maintain competitive pricing and product stability in your local market.