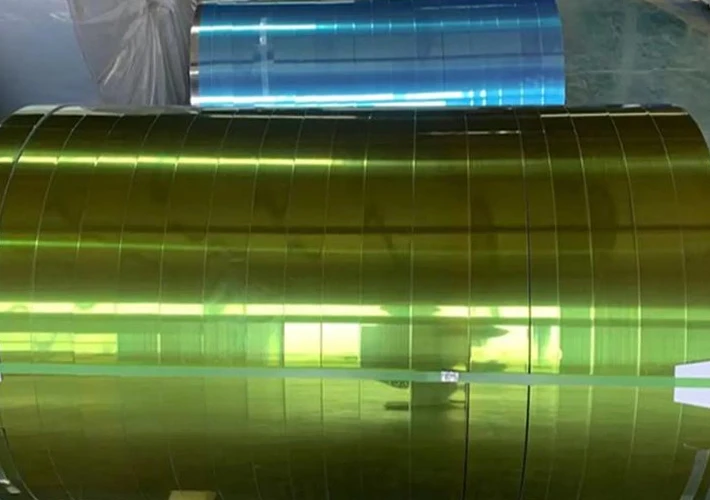

Aluzinc steel coils are one of the most widely used coated steel products in modern construction, roofing, appliances, automotive parts, and industrial manufacturing. Known for their exceptional corrosion resistance and excellent appearance, Aluzinc steel coils have become a preferred alternative to traditional galvanized steel in many markets.

This comprehensive guide explains everything you need to know about Aluzinc steel coils—including their composition, advantages, production technology, applications, price trends, and how to choose a reliable supplier in China. As a professional Chinese Aluzinc and coated steel coil manufacturer, we will also share key procurement insights valuable for global distributors and project contractors.

What Are Aluzinc Steel Coils?

Aluzinc steel coils—also known as Galvalume steel coils—are cold-rolled steel sheets coated with an alloy consisting of:

- 55% Aluminum

- 43.4% Zinc

- 1.6% Silicon

This coating is applied using the hot-dip process, forming a durable protective barrier on the surface of the steel substrate. The microstructure of the coating consists of aluminum-rich and zinc-rich phases, giving Aluzinc both strong corrosion resistance and excellent heat reflectivity.

Aluzinc steel coils are internationally standardized and often referred to as:

- GL coils (Galvalume Coil)

- AZ coated steel coils

- Alu-Zinc coated steel coils

How Aluzinc Works

The coating protection mechanism works in two ways:

Barrier Protection (Aluminum Component)

Aluminum forms a stable oxide layer, preventing oxygen and moisture penetration.

Galvanic Protection (Zinc Component)

Zinc sacrifices itself when the cut edges of steel are exposed, slowing corrosion.

Silicon Content

Ensures strong adhesion between the steel substrate and Alu-Zinc coating.

This unique combination allows Aluzinc steel coils to perform 2–6 times better than traditional galvanized coils in outdoor environments.

Material Composition & Performance Properties

Aluzinc steel coils are engineered to deliver superior performance across various physical, mechanical, and chemical parameters. These qualities make them ideal for long-term outdoor applications.

1.Corrosion Resistance

Aluzinc’s corrosion resistance is one of its biggest advantages. Thanks to the dual protection mechanism, its outdoor lifespan can reach:

- 25–35 years in normal environments

- 15–25 years in coastal environments

- More than 3x the life of galvanized steel under identical conditions

This is why Aluzinc is widely used in roofing, siding, and structural components.

2.Heat Resistance

Aluzinc can withstand temperatures up to 315°C without discoloration or loss of mechanical properties.

This makes it suitable for:

- Chimney pipes

- Ovens and heating equipment

- Industrial exhaust systems

3.Heat Reflectivity

Aluzinc’s reflectivity is much higher than galvanized steel:

- Solar reflectivity: up to 80%

- Reduces building cooling loads

- Enhances energy efficiency

This is one reason Alu-Zinc coated sheets are used for cool roofing systems in hot-climate regions.

4.Surface Appearance

Aluzinc coils typically have:

- A smooth, shiny surface

- Crystal-like spangle patterns (small, regular, or zero spangle)

- Good paint adhesion for pre-painted steel (PPGL)

The decorative metallic appearance is widely favored in architecture and interior use.

5.Mechanical Strength

Depending on grade, Aluzinc steel coils can be produced with various mechanical properties:

- Soft commercial grade

- Structural grade

- High-tensile grade for roll-forming applications

Typical yield strength ranges from 220 MPa to 550 MPa.

Advantages of Aluzinc Steel Coils

Below are the major reasons why Aluzinc coils are widely used by global distributors and contractors.

1.Longer Service Life

Compared with galvanized steel:

- Aluzinc lasts 3–6 times longer in outdoor environments

- Better cut-edge protection

- Better rust resistance in coastal and industrial zones

2.High-Temperature Performance

Aluzinc maintains coating stability under high temperatures, making it suitable for:

- Solar reflectivity panels

- Industrial ovens

- HVAC systems

3.Better Formability

Aluzinc provides excellent machinability:

- Roll-forming

- Pressing

- Bending

- Punching

Coating adhesion remains stable even after deformation.

4.Cost-Effective Alternative to Stainless Steel

In many outdoor applications, Aluzinc provides similar corrosion resistance at one-third the cost of stainless steel.

5.Excellent Appearance

Its metallic finish and controlled spangle give it a premium appearance suitable for visible installations.

6.Ideal Substrate for Pre-Painted Coils (PPGL)

Aluzinc is the base material for PPGL coils. The coating ensures:

- Strong paint adhesion

- Longer color retention

- Minimized chalking or peeling

Common Applications of Aluzinc Steel Coils

Aluzinc steel coils are widely used across construction, manufacturing, automotive, and industrial sectors.

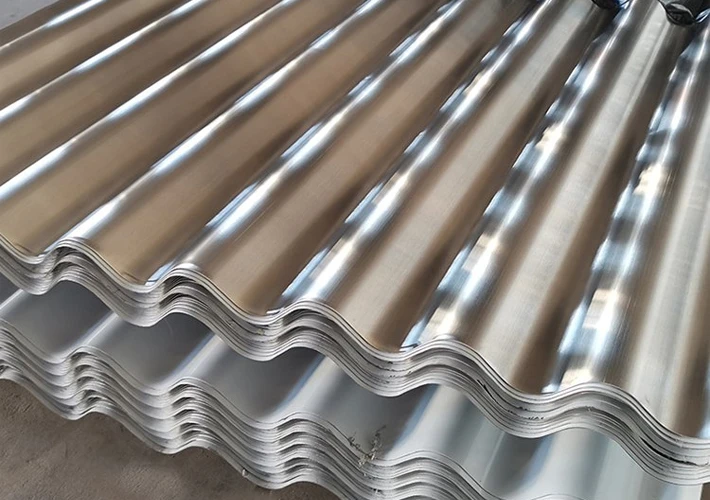

1.Roofing & Cladding

- Corrugated roofing sheets

- Standing seam roofs

- Wall cladding panels

- Insulated sandwich panels

These are especially common in:

- Warehouses

- Factory buildings

- Residential houses

- Agricultural barns

2.HVAC & Ventilation Systems

- Air ducts

- HVAC covers

- Industrial chimneys

High temperature resistance makes Aluzinc ideal for these applications.

3.Automotive Industry

- Exhaust components

- Underbody parts

- Reinforcement brackets

4.Home Appliances

- Refrigerator backing panels

- Oven liners

- Microwave outer shells

5.Electrical & Industrial Equipment

- Cable trays

- Transformer housings

- Solar photovoltaic mounting components

6.Pre-Painted Steel (PPGL) Production

Most PPGL producers use Aluzinc coils as the base material because of their superior paint adhesion and corrosion resistance.

Aluzinc vs. Galvanized vs. Galvanneal — Which Is Better?

| Feature | Aluzinc (Galvalume) | Galvanized Steel | Galvanneal Steel |

|---|---|---|---|

| Coating | 55% Al + 43.4% Zn + Si | 100% Zn | Zinc-Iron Alloy |

| Corrosion Resistance | ★★★★★ | ★★☆☆☆ | ★★★☆☆ |

| Lifespan | 25–35 years | 5–15 years | 10–20 years |

| Heat Resistance | High | Medium | Medium |

| Cut Edge Protection | Excellent | Good | Good |

| Appearance | Shiny, smooth | Spangle | Matte |

| Cost | Medium | Low | Medium |

For roofing, cladding, and long-term outdoor applications, Aluzinc is the most cost-effective choice.

How to Choose High-Quality Aluzinc Steel Coils

As a China Aluzinc steel coil factory, we work with many distributors worldwide. Below are key buyer tips to ensure you choose the right material and supplier.

1.Check Coating Weight (AZ50–AZ200)

Common coating weights:

- AZ50 – Indoor structures

- AZ70 – Light outdoor use

- AZ100 – Roofing, cladding

- AZ150 – High corrosion resistance

- AZ185–AZ200 – Coastal/industrial zones

AZ150 is the most widely used grade globally.

2.Check Base Steel Grade

Choose based on end use:

- Soft commercial (DC51D) for bending

- Structural steel (S280GD/S350GD) for roofing

- High-strength (S550GD) for cold-forming applications

3.Surface Options

- Regular spangle

- Small spangle

- Zero spangle

Choose based on aesthetic requirements.

4.Thickness and Width

Standard ranges:

- Thickness: 0.12–2.0 mm

- Width: 600–1250 mm

Custom sizes available from Chinese mills.

5.Choose a Reliable Factory, Not a Trader

Why importers prefer Chinese factories:

- Lower production costs

- High production capacity

- Stable and customizable quality

- Faster delivery time

- Full export documentation (CO, Form E, Form A, etc.)

As a China-based coated steel manufacturer, we provide:

- Aluzinc coils (GL)

- Prepainted Galvalume coils (PPGL)

- Galvanized coils (GI)

- PPGI coils

All meeting international standards (ASTM, JIS, EN).

Conclusion

Aluzinc steel coils have become one of the most durable and cost-effective coated steel solutions in modern construction and manufacturing. Their excellent corrosion resistance, heat reflectivity, surface aesthetics, and long lifespan make them superior to traditional galvanized steel in most applications.

For global importers, contractors, and distributors, Aluzinc provides an ideal balance between performance and cost. When sourced from a reliable Chinese factory, it becomes even more competitive in the international market.