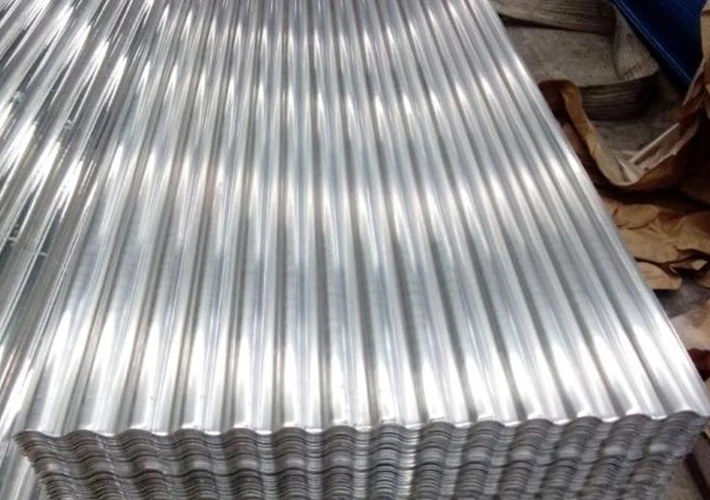

Galvanized iron (GI) roofing sheets are among the most widely used metal roofing materials across residential, commercial, industrial, and agricultural construction sectors. Their combination of durability, cost-effectiveness, corrosion resistance, and structural strength makes them a long-standing favorite in both developed and emerging markets. Whether used for roofing, wall cladding, fencing, or infrastructural protection, GI sheets remain essential materials in modern architecture.

As a China-based roofing materials manufacturer & exporter, we supply high-quality galvanized iron roofing sheets to global wholesalers, contractors, hardware distributors, and construction companies. In this article, we will explore the main uses of galvanized iron roofing sheets, their advantages, specifications, installation scenarios, and why global buyers continue to rely on GI roofing for large-scale projects.

What Are Galvanized Iron Roofing Sheets?

Galvanized iron sheets are carbon steel sheets coated with a protective layer of zinc through a manufacturing process such as:

- Hot-dip galvanizing (HDG)

- Electro-galvanizing (EG)

- Galvalume (55% Aluminum-Zinc coating)

The zinc layer shields the underlying steel from moisture, oxygen, and environmental contaminants, greatly improving durability and rust resistance.

Common Technical Features

| Feature | Details |

|---|---|

| Base Material | Carbon steel (SGCC, DX51D, Q195, Q235) |

| Coating | Zinc coating 40–275 g/m² |

| Thickness | 0.12mm – 1.2mm |

| Width | 600–1250mm |

| Length | Custom-cut |

| Surface | Regular spangle, zero spangle, matte, glossy |

| Profile | Corrugated, trapezoidal, ribbed, tile profile |

These specifications make GI roofing sheets adaptable for different environments—from tropical regions with heavy rain to cold areas with snow load.

Main Use of Galvanized Iron Roofing Sheets

Galvanized iron roofing sheets are primarily used for roofing in a wide variety of construction projects. However, roofing is just the beginning. GI sheets serve numerous structural and architectural purposes.

Below are the main applications, explained in detail for wholesalers, contractors, and B2B buyers.

1.Roofing for Residential Buildings

The most common use of galvanized iron sheets is residential roofing. Their lightweight and anti-rust properties make them ideal for housing in urban and rural areas.

Why Homeowners Prefer GI Roofing:

- Low maintenance

- Long lifespan (20–40 years depending on coating)

- Reflects heat, improving indoor comfort

- Quick installation reduces labor cost

- Available in various colors and profiles

Typical Residential Applications

- Houses and private villas

- Prefabricated houses

- Rural housing upgrade projects

- Mobile homes and container houses

- Dormitories and staff accommodations

GI corrugated sheets remain the most economical roofing option in developing countries, especially in Africa, Southeast Asia, South America, and South Asia.

2.Roofing for Commercial Buildings

GI roofing sheets are widely used in commercial projects due to their efficiency and cost advantages.

Common Commercial Applications

- Shopping malls

- Office buildings

- Schools and universities

- Hospitals

- Bus stations

- Parking lots

- Sports facilities

Commercial developers choose GI sheets because they offer:

- Strong weather resistance

- Modern appearance

- Fast installation for large roof areas

- Compatibility with insulation materials

This makes them ideal for large public infrastructure where durability and cost control are both important.

3.Industrial Roofing and Cladding

Industrial construction is one of the biggest markets for galvanized iron roofing sheets.

Industries Using GI Roofing

- Manufacturing plants

- Warehouses

- Logistics centers

- Workshops

- Processing factories

- Textile and garment factories

- Food processing plants

- Chemical plants (use thicker zinc coating)

Reasons GI Sheets Dominate Industrial Construction

- High tensile strength

- Can withstand industrial fumes and humidity

- Anti-corrosion coating reduces long-term maintenance

- Fire-resistant and suitable for safety requirements

- Long spans possible with trapezoidal profile

For industrial buyers, GI sheets offer the best balance between strength, durability, and cost efficiency.

4.Agricultural Buildings and Rural Infrastructure

Galvanized iron roofing sheets are highly popular in farming and agricultural facilities.

Typical Agricultural Uses

- Barns

- Poultry houses

- Cattle sheds

- Grain storage warehouses

- Greenhouse structures

- Machinery sheds

- Rural market buildings

- Water pump sheds

Farmers and agricultural companies prefer GI sheets because they provide:

- Excellent protection from rain, wind, and UV exposure

- Affordable material for large roof areas

- Resistance to animal waste and moisture

- Good ventilation performance

With agriculture expanding across Africa, South Asia, and Latin America, GI roofing demand continues to grow.

5.Wall Cladding for Buildings

Beyond roofing, galvanized iron sheets are also used as external wall cladding for commercial and industrial buildings.

Benefits of GI Wall Cladding

- Enhances thermal insulation when combined with PU foam or rock wool

- Provides a modern industrial appearance

- Can withstand UV rays and heavy rain

- Lightweight yet strong

- Lower cost than aluminum composite panels

Typical Wall Cladding Projects

- Warehouse facades

- Factory exterior walls

- Shopping mall facades

- Cold storage facilities

- Temporary construction site buildings

GI wall cladding is especially common in prefabricated steel structure buildings.

6.Fencing and Boundary Protection

GI corrugated sheets are also widely used as fencing materials.

Uses in Fencing

- Construction site barricades

- Temporary event fencing

- Urban boundary walls

- Farm fencing

- Industrial perimeter barriers

Why GI Sheets for Fencing?

- Stronger than PVC boards

- Long outdoor lifespan

- Low maintenance

- Resistant to harsh environments

- Easy to install and cut

Many contractors prefer GI sheets for fencing due to their durability and visibility barrier function.

7.Transportation and Infrastructure

GI sheets play an important role in infrastructure development.

Typical Uses

- Highway guard houses

- Railway sheds

- Road signage backing plates

- Bridge walkway covers

- Airport hangars

- Bus station roofing

Government projects often choose GI sheets due to:

- Long lifespan

- Strong corrosion resistance

- Low cost for large-scale infrastructure

These applications emphasize the material’s structural stability and long-term performance.

8.Prefabricated Houses & Modular Construction

The global trend toward modular and prefabricated construction has increased the use of galvanized iron roofing sheets.

Applications in Prefab Construction

- Container homes

- Modular classrooms

- Emergency shelters

- Labor camps

- Military housing

- Remote area buildings

GI roofing is ideal for prefabricated projects because it is:

- Lightweight

- Easy to transport

- Suitable for fast assembly

- Compatible with insulation layers

- Resilient in harsh environments

9.Water Harvesting Systems (Rainwater Management)

Corrugated galvanized iron sheets are commonly used in rainwater collection systems.

Reasons They Are Suitable for Water Harvesting

- Smooth, clean surface

- Zinc coating reduces contamination

- Long lifespan ensures reliable water supply

- Can withstand high rainfall regions

- Easy to install with gutter systems

They are widely used in rural areas, schools, agricultural farms, and community water supply projects.

10.DIY, Small Structures & Temporary Buildings

GI sheets are frequently used in backyard and temporary structures such as:

- Sheds

- Tool storage rooms

- Garages

- Carports

- Outdoor kitchens

- Garden houses

- Kiosks and booths

Their ease of handling, cutting, and installation make them suitable for DIY enthusiasts and small contractors.

Advantages of Galvanized Iron Roofing Sheets

To understand their popularity, we must highlight the key advantages GI roofing sheets offer.

1.Excellent Corrosion Resistance

Thanks to the zinc coating, GI sheets resist:

- Moisture

- Rust

- Chemicals

- Environmental oxidation

This greatly extends service life.

2.Long Lifespan (20–40 Years)

Lifespan depends on:

- Zinc coating weight

- Local climate

- Maintenance

With proper installation, GI sheets can last decades.

3.High Strength and Durability

GI roofing sheets can withstand:

- Heavy rain

- Strong winds

- Hail impact

- Snow load

This makes them ideal for complex climates.

4.Lightweight & Easy to Install

Lighter than traditional tiles or concrete roofing:

- Lower labor cost

- Faster project completion

- Reduced structure load

5.Cost-Effective for Large Projects

GI roofing offers one of the lowest costs per square meter among metal roofing materials.

6.Fire-Resistant and Safe

Steel does not ignite, making GI roofing suitable for factories, warehouses, and public buildings.

7.Wide Range of Profiles & Colors

Available options include:

- Corrugated sheets

- Trapezoidal sheets

- Tile-profile sheets

- Color coatings (PPGI / PPGL)

Why Import Galvanized Iron Roofing Sheets from China?

(Highlighting Factory Strength)

As a galvanized roofing sheet factory in China, we offer several advantages for global wholesalers and engineering contractors:

1.Stable Quality (ISO, CE, SGS Certifications)

Strict quality control ensures consistent zinc coating, thickness, and mechanical performance.

2.Competitive Factory Prices

Compared with other countries, China provides:

- Lower production cost

- Advanced galvanizing lines

- Large-scale capacity

Resulting in better pricing for B2B buyers.

3.Full Range of Roofing Materials

We supply:

- GI sheets

- PPGI sheets

- Galvalume sheets

- Sandwich panels

- Roofing accessories

- Screw fasteners and ridge caps

Buyers can complete one-stop purchasing, reducing logistics cost.

4.Fast Delivery for Bulk Orders

With multiple production lines, we support:

- Large orders

- Custom specifications

- Short lead times

5.OEM & Customized Service

We offer:

- Customized color

- Special widths

- Branding and packaging

- Customized profile rollers

For wholesalers, this means enhanced competitiveness in local markets.

Conclusion

Galvanized iron roofing sheets are primarily used for roofing, but their versatility extends far beyond that. They serve critical roles in:

- Residential buildings

- Commercial and industrial construction

- Agricultural facilities

- Prefabricated structures

- Infrastructure projects

- Wall cladding and fencing

With their durability, affordability, and wide application range, GI roofing sheets remain one of the most reliable materials in the global construction industry.

As a professional galvanized iron roofing sheet manufacturer in China, we support global wholesalers with stable quality, competitive prices, and fast delivery. If you need bulk orders or customized specifications, we can offer complete solutions for your market.