Roofing nails are one of the most essential fasteners used in modern construction projects. Whether it is residential roofing, commercial buildings, modular housing, or large-scale government projects, roofing nails play a critical role in ensuring durable, stable, and long-lasting roof structures. In recent years, assembled roofing nails—also known as collated roofing nails—have become increasingly popular in international markets due to their superior efficiency and performance.

As a professional roofing materials and fastener supplier from China, we work with wholesalers, distributors, and project contractors worldwide. Many customers ask: Why choose assembled roofing nails instead of bulk loose nails?

This article offers a detailed, professional, and data-rich explanation to help global buyers understand the product advantage, manufacturing process, applications, and reasons why assembled roofing nails are preferred in modern construction.

What Are Assembled Roofing Nails?

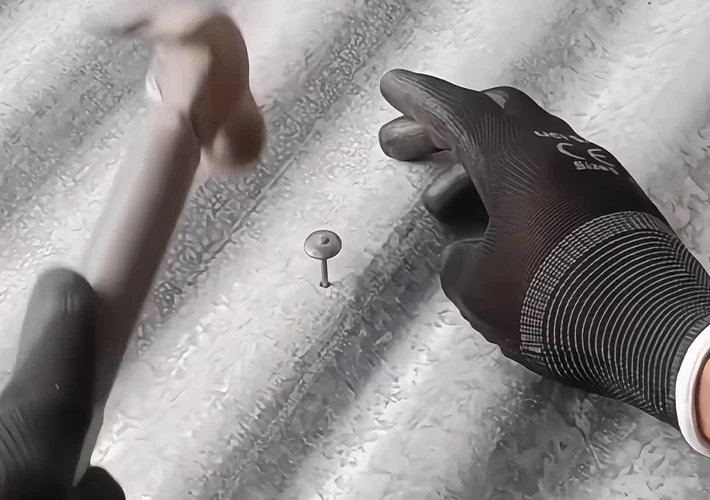

Assembled roofing nails are roofing nails that are pre-collated into strips, coils, or sheets for rapid firing with pneumatic nail guns. Instead of using nails one by one manually, assembled roofing nails allow roofers to load hundreds of nails into a tool and complete roofing installation far more efficiently.

These nails are typically:

- Electro-galvanized or hot-dip galvanized

- Made of high-carbon steel or Q195 steel

- Connected with wire, plastic, or paper tape

- Packaged in coils (most common) for coil nailers

Because of this design, assembled roofing nails have become the standard fastener in fast-paced roofing projects, especially asphalt shingles, composite shingles, and soft roofing materials.

Common Types of Assembled Roofing Nails

To better understand their advantages, global buyers should first know the major types available in the market.

1.Wire-Coil Roofing Nails

The most widely used category. Nails are arranged into coils using thin wire.

- Available in 15-degree angle

- 120–150 nails per coil

- Suitable for most standard coil roofing nailers

- Strong and corrosion-resistant

2.Plastic-Coil Roofing Nails

Coils connected with plastic carriers.

- Cleaner firing

- Less residue

- Smooth feeding in nailers

3.Paper-Tape Assembled Roofing Nails

Nails arranged in strips with paper tape.

- Lightweight

- Suitable for certain nail gun models

- Less flying debris

4.Hot-Dip Galvanized Assembled Roofing Nails

These nails have the strongest corrosion resistance.

- Preferred for coastal, rainy, and humid environments

- Longer lifespan in storm-prone regions

- Meets high-standard building codes in USA, Europe, and Australia

5.Stainless Steel Assembled Roofing Nails

Premium option for maximum service life.

- Used in luxury housing

- High-end roofing shingles

- Marine environments

The Key Advantages of Assembled Roofing Nails

Below are the core benefits that make assembled roofing nails the first choice for contractors worldwide.

1.Extremely High Construction Efficiency

One of the largest advantages is speed.

- Manual nailing: 2–3 nails per minute

- Pneumatic nailing with assembled nails: 12–20 nails per second

This means:

- 6–10× higher efficiency

- Shorter project timelines

- Lower labor cost

- Fewer worker fatigue issues

- Perfect for large roofing projects

In countries with rising labor costs—USA, Canada, Australia, UK—assembled roofing nails significantly reduce construction expenses.

2.Consistent Nail Placement & Reduced Installation Errors

Roof projects require precise:

- Nail spacing

- Nail depth

- Shingle fastening strength

Using a nail gun with assembled roofing nails ensures:

- Stable depth

- Uniform angle

- No bending of nails

- No misfires when using high-quality collated nails

This leads to:

- Longer roof lifespan

- Better wind resistance

- Compliance with building standards (e.g., ICC, ASTM, CE)

3.Higher Productivity with Less Physical Labor

Compared with traditional manual roofing nails:

- Workers do not have to bend or squat frequently

- No need to manually pick nails

- Reduced hand injuries or finger strikes

- Less fatigue even in summer roofing work

This is a major advantage for professional roofing teams and large construction contractors.

4.Improved Safety on Roofing Sites

Assembled roofing nails improve safety in three ways:

Reduced scattered sharp nails on roofs and floors

Nail guns minimize hammer-related injuries

Boxes and coils are compact, reducing jobsite clutter

Safety is especially important in:

- Steep-slope roofing

- Multi-story roofing

- Industrial roofing projects

5.Higher Quality Nail Coating & Corrosion Resistance

Assembled roofing nails often come with zinc-coated surfaces:

- Electro-galvanized (EG)

- Hot-dip galvanized (HDG)

- Mechanical galvanized

- Stainless steel

Coil nails are typically sold with uniform coating thickness, which assures strong resistance to:

- Acid rain

- Moisture

- Salty wind

- Freeze-thaw cycles

This makes assembled roofing nails ideal for global climates.

6.Reduced Waste & Lower Material Costs

Traditional loose nails often cause:

- Nail loss during transport

- More bent nails

- More on-site waste

Assembled roofing nails reduce scrap:

- 98%+ utilization rate

- Lower waste disposal cost

- Lower project material losses

7.Better Compatibility with Modern Construction Tools

Today, almost all professional roofing contractors use:

- 15-degree pneumatic coil nailers

- Gas-powered nail guns

- Electric roofing nailers

Assembled nails are specifically designed for these machines, ensuring:

- Quick reloading

- Smooth firing

- Minimal jamming

High-quality collated nails mean fewer interruptions and more stable output.

8.Suitable for a Wide Range of Roofing Materials

Assembled roofing nails are widely used for:

- Asphalt shingles

- Composite roofing shingles

- Waterproof membranes

- Underlayments

- Felt

- Plywood sheathing

- OSB board

- Fiber-cement shingles

Their versatility makes them ideal for global roofing distributors.

9.Stronger Holding Power

Assembled roofing nails often have:

- A wide head

- Smooth or ring shank designs

Ring shank nails provide up to 40% higher pull-out resistance, especially in windy areas.

This ensures roofs stay intact even during:

- Hurricanes

- Heavy storms

- Snow and freeze cycles

10.Reduced Labor Cost for Contractors

With construction labor costs increasing globally:

- USA roofing labor: $40–$65/hour

- Australia roofing labor: $55–$80/hour

- UK roofing labor: £25–£40/hour

Using assembled roofing nails minimizes labor time and overall project cost.

For contractors, this advantage directly improves profitability.

How Assembled Roofing Nails Are Manufactured (Factory Insights)

As a professional roofing fastener factory in China, here is a simplified overview of the production process:

1.Wire Rod Selection

High-quality carbon steel (Q195/Q235) ensures:

- Strength

- Bend resistance

- Consistency

2.Nail Forming Process

Includes:

- Wire drawing

- Cold-heading

- Shank forming

- Point forming

Precision CNC machinery ensures dimension accuracy.

3.Surface Treatment

Galvanizing options:

- 40–120 g/m² EG coating

- 120–350 g/m² HDG coating

Hot-dip galvanized nails are dipped into molten zinc for maximum corrosion resistance.

4.Collation

Depending on nail type:

- Wire collation

- Plastic collation

- Paper collation

5.Quality Control

Checks include:

- Nail length tolerance

- Diameter tolerance

- Zinc coating thickness

- Withstanding pressure test

- Salt spray corrosion test

- Loading test (gun compatibility test)

6.Packaging

For export:

- 7200–9000 nails per carton

- Custom OEM packaging

- Moisture-proof boxes

- Palletized for container shipping

Our factory supports:

- OEM logos

- Private label

- Custom carton design

- Mixed model loading

Global Applications of Assembled Roofing Nails

Assembled roofing nails are popular in:

1.North America (USA & Canada)

- Asphalt shingles

- Roofing underlayments

- OSB & plywood sheathing

- Hurricane-resistant construction

2.Europe

- Composite roofing

- Waterproof membranes

- Modular homes

3.Australia & New Zealand

- Coastal roofing

- High UV and corrosion environments

4.Middle East

- Large commercial roofing

- High-temperature resistance demand

5.Africa & South America

- Affordable housing

- Rapid construction projects

Why Import Assembled Roofing Nails from China?

China has become the largest global supplier due to:

1.Competitive Pricing

Factory-direct pricing saves 20–40% compared with local suppliers.

2.Advanced Production Equipment

Modern collation machines ensure stable quality.

3.Strong Export Experience

Fast shipment & customs familiarity.

4.Large Production Capacity

Suitable for wholesalers & national distributors.

5.Customization Available

- Branding

- Packaging

- Size

- Coating

How to Choose the Right Assembled Roofing Nails for Your Market

1.Choose the right coating

- Humid or coastal areas → HDG nails

- Dry climate → EG nails

2.Choose the right shank type

- Ring shank → stronger holding power

- Smooth shank → easy penetration, lower cost

3.Confirm nail gun compatibility

Most roofing nails are 15-degree.

4.Choose a reliable supplier

Key indicators:

- ISO certification

- Salt-spray test reports

- Nail gun firing test videos

- Stable monthly capacity

Conclusion — Why Assembled Roofing Nails Are the Best Choice for Modern Roofing

Assembled roofing nails provide a long list of advantages:

- Faster construction

- Higher accuracy

- Better safety

- Lower labor cost

- Stronger corrosion resistance

- High compatibility with roofing nailers

- Reduced material waste

- Excellent performance in global climates

For roofing contractors, wholesalers, and distributors, assembled roofing nails offer significant economic and performance benefits.