In the roofing industry, even the smallest components can make a big difference in durability and performance. Roofing nails may seem insignificant, but their material determines whether a roof will withstand decades of exposure or fail within a few years. Among the many types, stainless steel roofing nails and galvanized roofing nails are the two most commonly used options.

But which one is better? The answer depends on your project environment, material pairing, and long-term goals.

(We are a professional nail manufacturer and supplier in China, offering high-quality stainless steel and galvanized roofing nails for global clients. If you are looking for a reliable OEM partner or wholesale supplier, contact us for free samples and quotations.)

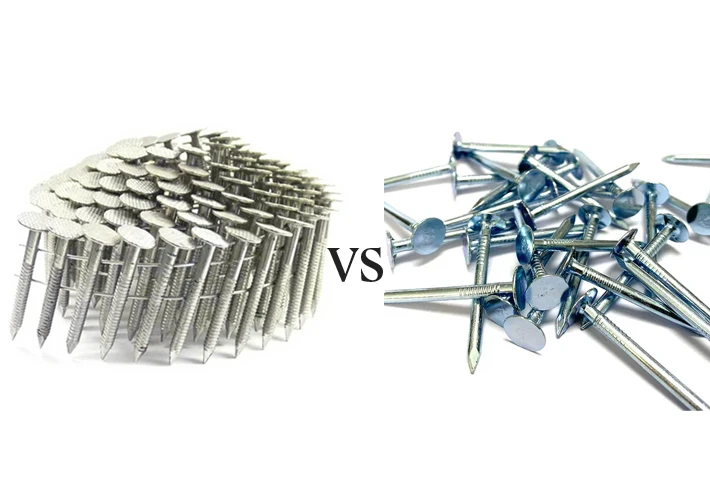

Overview: Two Common Types of Roofing Nails

Stainless steel roofing nails are made from corrosion-resistant alloys like 304 or 316 stainless steel. They are ideal for environments with high humidity, salt exposure, or chemical pollutants.

Galvanized roofing nails, on the other hand, are made of carbon steel coated with a layer of zinc. This zinc coating acts as a barrier against moisture and oxygen, slowing down corrosion. Depending on the coating process, they are divided into:

- Electro-galvanized nails – thinner coating, lower cost, moderate rust protection.

- Hot-dip galvanized nails (HDG) – thicker coating, stronger adhesion, and longer lifespan.

For most roofing projects, these two nail types dominate the market because of their balance between performance and cost.

Material and Manufacturing Differences

Stainless Steel Nails

- Composition: Typically made of 304 or 316 stainless steel.

- 304 stainless steel contains chromium and nickel, offering strong corrosion resistance.

- 316 stainless steel includes molybdenum (Mo), providing extra protection against chlorides and salt spray.

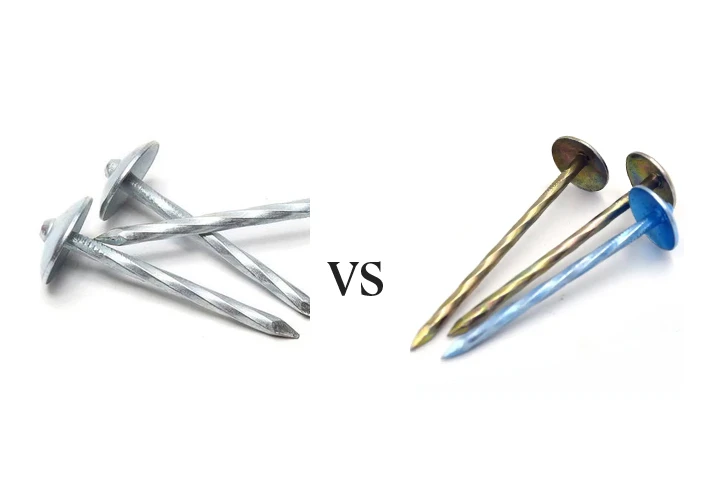

Galvanized Nails

Base material: Carbon steel or mild steel.

Coating process:

- Electro-galvanized – achieved through an electroplating process, resulting in a smooth but thin zinc layer.

- Hot-dip galvanized – nails are dipped in molten zinc, forming a thick, rough coating that lasts longer outdoors.

In terms of corrosion performance, 316 stainless steel nails are the best, followed by hot-dip galvanized, and lastly electro-galvanized.

Corrosion Resistance and Weather Durability

The biggest difference between stainless steel and galvanized nails lies in how they handle corrosion.

- Stainless steel nails do not rely on coatings. The chromium in stainless steel forms a self-healing oxide layer that resists rust and pitting even when scratched.

- Galvanized nails depend on the zinc coating to protect the steel underneath. Once the coating wears off or is damaged, the exposed steel will rust rapidly.

| Environment | Recommended Nail Type | Expected Lifespan |

|---|---|---|

| Coastal or marine areas | 316 Stainless Steel | 30+ years |

| Industrial or humid zones | 304 Stainless Steel or Hot-Dip Galvanized | 15–25 years |

| Dry or inland regions | Hot-Dip Galvanized | 10–20 years |

| Interior or sheltered roofing | Electro-Galvanized | 5–10 years |

So, while galvanized nails can provide sufficient protection in normal environments, stainless steel remains the premium option for long-term durability—especially for coastal construction, resorts, and export projects.

Mechanical Strength and Holding Power

Both stainless steel and galvanized nails offer high tensile strength, but some distinctions exist:

Holding power depends more on the nail’s shape than material.

- Ring-shank or annular nails have better grip and resistance to withdrawal.

- Smooth-shank nails are easier to drive but may loosen over time.

Tensile and shear strength:

Galvanized nails (carbon steel) often have slightly higher tensile strength, while stainless steel nails excel in long-term integrity because they don’t weaken from corrosion.

For roofing materials such as asphalt shingles, metal panels, and slate tiles, ring-shank stainless steel nails are widely used for maximum security.

Cost, Availability, and Long-Term Value

Cost is often the deciding factor for project managers and importers.

| Nail Type | Relative Cost | Maintenance Cost | Total Lifecycle Cost |

|---|---|---|---|

| Electro-Galvanized | Low | High | Medium |

| Hot-Dip Galvanized | Medium | Moderate | Medium-Low |

| Stainless Steel | High | Very Low | Low |

Although stainless steel nails have a higher upfront price, their long-term cost is lower due to reduced replacement and maintenance. For high-value projects or coastal regions, stainless steel is the smarter investment.

(As a leading nail manufacturer in China, our factory provides both galvanized and stainless steel roofing nails in multiple grades and finishes. We offer competitive factory prices for bulk orders and OEM packaging for distributors worldwide.)

Galvanic Corrosion: Why Matching Metals Matters

One of the most overlooked issues in roofing projects is galvanic corrosion—a chemical reaction that occurs when dissimilar metals contact each other in the presence of moisture.

For example:

- Using galvanized nails with copper roofing can cause rapid corrosion due to electrochemical potential differences.

- Stainless steel nails are more compatible with a wider range of roofing materials, including aluminum, zinc, and composite panels.

To prevent galvanic corrosion:

- Match nail metal type with roofing sheet metal whenever possible.

- Use isolating materials like rubber washers or sealants if different metals must be combined.

- Avoid using electro-galvanized nails in exposed outdoor copper or aluminum roofing.

Standards and Quality Assurance

When purchasing in bulk, always check the following quality standards:

- ASTM A153 – Hot-dip galvanized coating standards.

- ASTM F1667 – Standard specification for driven fasteners.

- ISO 3506 – Stainless steel fastener specifications.

- Salt spray test (ASTM B117) – Verifies corrosion resistance.

Reputable factories should provide:

- Material test reports (MTR) for stainless steel.

- Coating thickness certificates for galvanized nails.

- Batch inspection reports before shipment.

(Our factory strictly follows ASTM and ISO standards. Every shipment is inspected for coating thickness, tensile strength, and salt-spray performance to ensure consistency and quality.)

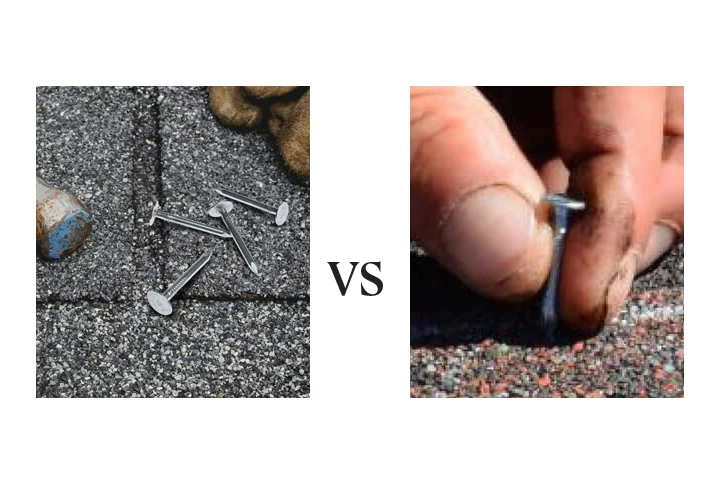

Application Scenarios and Recommendations

| Application Scenario | Recommended Type | Reason |

|---|---|---|

| Coastal roofing projects | 316 Stainless Steel Nails | Maximum corrosion resistance |

| Asphalt shingle roofs | Hot-Dip Galvanized Nails | Strong adhesion and cost-effective |

| Metal roofing systems | Match metal or use stainless steel | Avoid galvanic corrosion |

| Temporary structures or interiors | Electro-Galvanized Nails | Budget-friendly |

| Luxury villas or hotels | 304/316 Stainless Steel Nails | Long service life, no rust stains |

If your project involves export or long-term warranty, using stainless steel nails not only ensures durability but also enhances the brand reputation of your construction quality.

Procurement Tips for B2B Buyers

Specify material grade (304 or 316) in your purchase order.

Confirm coating method for galvanized nails (electro or hot-dip).

Request third-party inspection reports or salt-spray test results.

Ensure proper packaging with moisture-proof protection during shipment.

Order sample boxes for testing before placing bulk orders.

(We offer customized sample kits for roofing contractors and distributors. You can test our nails’ coating quality, hardness, and compatibility with your roofing materials before bulk purchasing.)

Conclusion: Which Roofing Nail Is Better?

| Comparison Aspect | Stainless Steel Nails | Galvanized Nails |

|---|---|---|

| Corrosion Resistance | Excellent | Good (HDG) / Fair (Electro) |

| Strength | Very High | High |

| Cost | Higher | Lower |

| Lifespan | 25–50 years | 10–20 years |

| Maintenance | Minimal | Occasional |

| Best for | Coastal, luxury, export projects | Inland, budget projects |

Final Verdict:

If your project is located near the sea, in high-humidity areas, or requires premium longevity — choose stainless steel roofing nails (preferably 316).

For most inland construction or standard projects — hot-dip galvanized nails provide excellent balance between cost and performance.

About Our Factory

We are a leading roofing nails manufacturer and exporter in China, specializing in:

- Stainless steel roofing nails (304, 316 grade)

- Hot-dip galvanized and electro-galvanized nails

- Umbrella roofing nails, common nails, and ring-shank nails

Our products are exported to over 50 countries, including the United States, South Africa, Nigeria, Kenya, and the Middle East.

With automated production lines, strict QC inspection, and OEM/ODM capabilities, we help global distributors and contractors reduce procurement costs while maintaining top quality.

Free sample box available

Contact us today to get factory price and product catalog!