Introduction

Roofing construction requires durable materials that can withstand harsh environmental conditions, including strong winds, rain, and temperature fluctuations. Among the essential materials used for roofing installation, umbrella roofing nails play a critical role. These specially designed nails not only secure roofing sheets but also prevent water leakage and rust formation, ensuring the longevity of the roof.

In this article, we’ll explore in detail what umbrella roofing nails are, their main features, types, manufacturing process, applications, and how to choose the right umbrella nails for your roofing projects. Whether you are a roofing contractor, distributor, or B2B importer, this guide provides everything you need to know about this vital roofing fastener.

What Are Umbrella Roofing Nails?

Umbrella roofing nails, also known as umbrella head nails, are a type of nail commonly used in roofing construction to fasten metal sheets, tiles, and other roofing materials to wooden or steel structures. They are named for their distinctive umbrella-shaped head, which provides a larger surface area for holding the roofing material firmly in place.

Unlike ordinary nails, umbrella roofing nails are designed with corrosion-resistant coatings such as galvanized zinc, aluminum, or stainless steel. These coatings protect the nail from rust and ensure long-term durability, especially in outdoor environments exposed to moisture.

The umbrella head also helps in preventing water penetration through nail holes, which is crucial for maintaining the waterproof performance of roofing systems.

Structural Design of Umbrella Roofing Nails

The design of umbrella roofing nails consists of three main parts:

Umbrella Head – The broad head distributes pressure over a larger surface area, ensuring that the roofing material stays flat and tight against the substrate. It also provides a decorative finish when exposed.

Shank – The shank is usually smooth, ringed, or twisted to provide varying levels of holding power depending on the application. Ring shanks offer better grip, while smooth shanks are easier to drive.

Point – The sharp point enables easy penetration into wood or other base materials without splitting the surface.

Each part of the umbrella roofing nail contributes to firm fastening, leak prevention, and corrosion resistance, which are vital for roofing applications.

Key Features of Umbrella Roofing Nails

Umbrella roofing nails are preferred in roofing projects due to their unique performance advantages. Below are the main features that distinguish them from ordinary nails:

3.1. Wide Umbrella Head Design

The wide head provides better coverage and prevents the roofing sheet from tearing or deforming during installation. It also helps in evenly distributing load and maintaining structural stability.

3.2. Excellent Corrosion Resistance

Most umbrella nails are made from high-carbon steel and are hot-dip galvanized or electro-galvanized to resist rust, oxidation, and environmental degradation. This feature makes them ideal for coastal or humid regions.

3.3. Strong Holding Power

The ring or twisted shank design provides exceptional holding power. This prevents nails from loosening over time due to wind uplift or vibration.

3.4. Leak Prevention

The combination of the umbrella head and a rubber or plastic washer underneath provides superior waterproofing. It effectively seals the hole created during nailing, ensuring no rainwater seeps through.

3.5. Aesthetic Appearance

Available in various colors and finishes, umbrella roofing nails can match roofing materials such as galvanized sheets, color-coated steel, or stone-coated tiles, improving the overall aesthetic appeal.

3.6. Long Service Life

Due to their strong structure and corrosion-resistant coating, umbrella roofing nails can last for more than 10–20 years, depending on the environment.

Common Types of Umbrella Roofing Nails

Umbrella roofing nails come in several types based on material, surface coating, and shank style. Let’s break down the most common types:

4.1. Hot-Dip Galvanized Umbrella Nails

These nails are coated with a thick layer of zinc through a hot-dip process. The zinc coating provides superior corrosion protection and durability, making them ideal for long-term outdoor use.

- Coating thickness: 40–100 g/m²

- Service life: 15–25 years

- Applications: Metal roofing sheets, wooden structures, and coastal installations.

4.2. Electro-Galvanized Umbrella Nails

These are coated using an electroplating process, resulting in a thinner and smoother zinc layer. They offer a more aesthetic appearance and are suitable for indoor or moderate-climate applications.

- Coating thickness: 5–20 g/m²

- Service life: 5–10 years

- Applications: Interior partitions, temporary roofs, and indoor decoration panels.

4.3. Stainless Steel Umbrella Nails

Made from stainless steel (commonly SS304 or SS316), these nails provide the highest resistance to corrosion and are ideal for highly humid or industrial environments.

- Material: 304/316 stainless steel

- Service life: 20–30 years

- Applications: Marine projects, tropical regions, and chemical facilities.

4.4. Aluminum Umbrella Nails

Lightweight and corrosion-resistant, aluminum umbrella nails are often used for lightweight roofing structures.

- Advantages: Light, rust-proof, non-magnetic

- Applications: Aluminum panels, lightweight roofing systems, and decorative projects.

4.5. Copper Umbrella Nails

Copper umbrella nails are known for their aesthetic finish and natural resistance to corrosion. They develop a patina over time, adding to their visual appeal.

- Applications: Luxury architectural roofing, copper panels, and antique-style buildings.

4.6. Colored Umbrella Nails

These are coated with polyester or PVC paint in various colors (red, green, blue, gray) to match roofing sheets. Besides being decorative, the paint layer also adds an extra layer of rust protection.

Specifications and Technical Parameters

| Parameter | Specification Range |

|---|---|

| Nail Length | 1″ to 4″ (25–100 mm) |

| Shank Diameter | 2.0 mm to 4.5 mm |

| Head Diameter | 9 mm to 20 mm |

| Material | Q195 / Q235 carbon steel, stainless steel, aluminum |

| Surface Treatment | Hot-dip galvanized, electro-galvanized, color-coated, or polished |

| Washer | EPDM rubber / PVC washer |

| Packing | 5 kg, 10 kg, or 25 kg/carton or bag |

Manufacturers may also customize specifications based on client requirements, such as head diameter, washer color, and nail length.

Manufacturing Process of Umbrella Roofing Nails

The production of umbrella roofing nails involves several precision steps to ensure quality and consistency:

Wire Drawing: Steel wire is drawn to the required diameter for nail production.

Cutting: The wire is cut into precise lengths.

Cold Heading: The umbrella head is formed using a nail-making machine.

Shank Forming: Depending on the design, the shank may be ringed or twisted.

Pointing: The nail point is sharpened for easy penetration.

Surface Treatment: Nails are galvanized or coated to improve corrosion resistance.

Washer Assembly: Rubber or plastic washers are attached.

Packaging: Finished nails are packed in boxes or bags for shipping.

Applications of Umbrella Roofing Nails

Umbrella roofing nails are widely used in both residential and commercial construction projects. Their versatility and durability make them suitable for multiple roofing materials and environments.

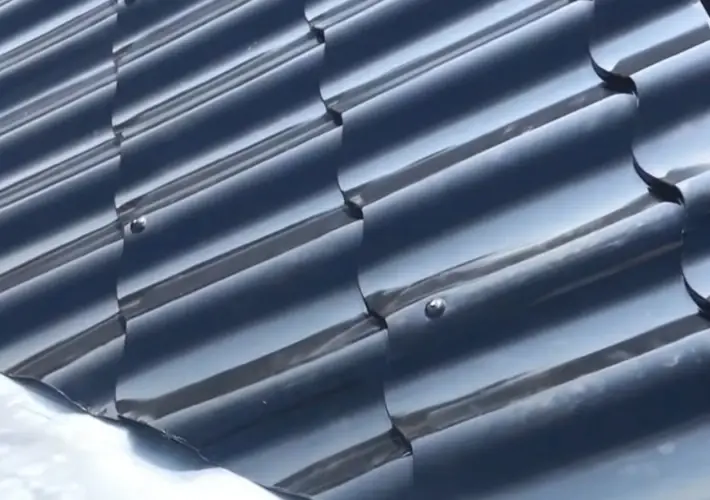

7.1. Metal Roofing Sheets

Used to fasten corrugated iron sheets, galvanized steel sheets, and color-coated roofing panels on warehouses, factories, and homes.

7.2. Stone-Coated Roofing Tiles

In stone-coated metal roofs, umbrella nails help secure tiles while preventing water leakage through their broad heads and washers.

7.3. PVC and UPVC Roofing Panels

Perfect for lightweight roofing systems, umbrella nails prevent cracking and ensure long-term fixation.

7.4. Wooden Roof Structures

They are used to fix roofing materials onto wooden trusses or purlins, ensuring firm anchorage and easy installation.

7.5. Agricultural and Industrial Buildings

Commonly used for barns, sheds, workshops, and temporary shelters due to their weather resistance and cost-effectiveness.

7.6. Tropical and Coastal Buildings

In areas prone to humidity and salt corrosion, hot-dip galvanized or stainless-steel umbrella nails ensure long-lasting protection.

Advantages of Using Umbrella Roofing Nails

Enhanced Waterproofing Performance – The umbrella head and washer combination effectively block water entry.

Corrosion Resistance – Zinc or stainless coatings prevent rust and oxidation.

Long Lifespan – With proper installation, nails can last over two decades.

Secure Fixation – Ring shanks resist pull-out, ensuring stability even in windy conditions.

Aesthetic Options – Available in various colors to match modern roofing designs.

Cost-Effective – Affordable compared to screw systems while providing reliable performance.

Easy Installation – Can be installed manually or with nail guns, saving labor time.

How to Choose the Right Umbrella Roofing Nail

Choosing the correct umbrella nail depends on your roofing type, environment, and budget. Below are key factors to consider:

9.1. Material Selection

- Hot-dip galvanized – Best for general outdoor use.

- Stainless steel – Best for humid, marine, or industrial areas.

- Aluminum – Best for lightweight roofs.

9.2. Length and Diameter

Select a nail length that penetrates the base material by at least 2.5 times the sheet thickness for firm holding.

9.3. Shank Type

- Smooth shank: Easier to drive, suitable for soft materials.

- Ring shank: Offers stronger grip and prevents loosening.

- Twisted shank: Provides maximum resistance to pull-out.

9.4. Washer Material

Use EPDM washers for better weather sealing and UV resistance.

9.5. Coating and Color

Choose a coating that complements your roofing sheet. For color roofs, use matching painted umbrella nails.

Comparison: Umbrella Roofing Nails vs Ordinary Nails

| Feature | Umbrella Roofing Nail | Ordinary Nail |

|---|---|---|

| Head Shape | Wide umbrella type | Flat round head |

| Waterproof Performance | Excellent | Poor |

| Corrosion Resistance | High (galvanized/stainless) | Low |

| Holding Power | Strong (ring/twisted shank) | Moderate |

| Service Life | 10–25 years | 2–5 years |

| Application | Roofing and outdoor | General construction |

The table clearly shows that umbrella roofing nails are a superior choice for roofing projects due to their strength, longevity, and waterproofing ability.

Maintenance and Installation Tips

- Always check for corrosion before installation.

- Use rubber washers to prevent water leakage.

- Avoid overdriving nails, which may damage the roofing sheet.

- For best results, install nails perpendicular to the sheet surface.

- Regularly inspect the roof every 2–3 years and replace any loose nails.

Market Overview and Export Trends

Umbrella roofing nails are in high demand globally due to the expansion of construction and roofing projects. The major importing regions include:

- Africa (Nigeria, Kenya, Ghana) – High demand for galvanized umbrella nails for metal roofing.

- Southeast Asia (Philippines, Indonesia, Malaysia) – Used widely in lightweight roofing systems.

- South America (Brazil, Peru, Chile) – Preference for color-coated umbrella nails for aesthetic roofs.

- Middle East – Demand for stainless steel and aluminum nails due to high temperatures and humidity.

China remains the largest manufacturer and exporter of umbrella roofing nails, offering high-quality products at competitive prices for global B2B buyers.

Conclusion

Umbrella roofing nails may seem like small components, but their role in ensuring a roof’s stability, waterproofing, and longevity cannot be overstated. With their unique umbrella-shaped head, anti-corrosion coating, and strong holding power, they provide a reliable solution for securing roofing sheets under various environmental conditions.

For distributors, contractors, and importers, choosing high-quality umbrella roofing nails from a reliable Chinese manufacturer ensures better performance, lower maintenance, and long-term customer satisfaction.

If you’re looking for factory-direct umbrella roofing nails with custom sizes, coatings, and packaging, contact our team today to get a competitive quotation for your market needs.