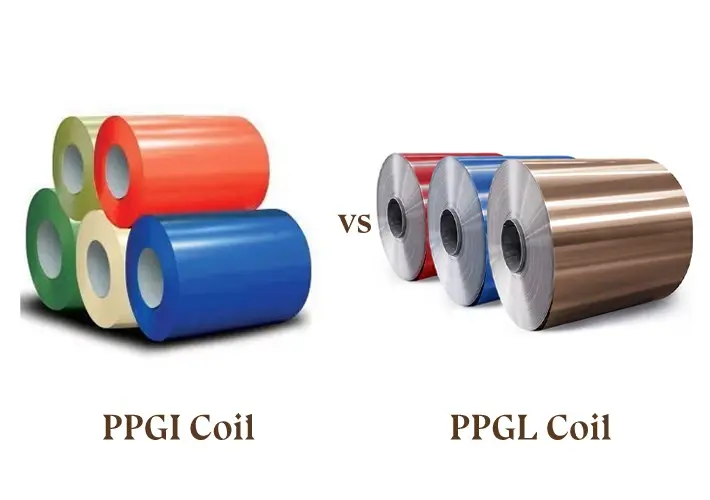

In the construction and manufacturing industries, pre-painted steel coils have become essential materials due to their durability, versatility, and aesthetic appeal. Among the most widely used coated steel products are PPGI (Pre-Painted Galvanized Iron) and PPGL (Pre-Painted Galvalume) coils.

While both serve similar functions and look nearly identical at first glance, they differ significantly in composition, coating, performance, and application suitability. Understanding these differences is crucial for builders, contractors, and distributors when selecting the right material for specific projects.

This article provides a detailed comparison between PPGI and PPGL coils, including their production process, characteristics, advantages, and key applications.

What is PPGI Coil?

PPGI stands for Pre-Painted Galvanized Iron. It refers to a galvanized steel coil that has been coated with a layer of zinc for corrosion resistance and then painted with a protective color coating.

1.1 Composition and Coating

- Base metal: Cold-rolled steel (CR steel)

- Coating layer: Pure zinc (≥99%)

- Coating weight: Commonly between 60–275 g/m²

- Paint system: Typically polyester (PE), silicon-modified polyester (SMP), PVDF, or polyurethane

1.2 Production Process

Cold-rolled steel base is cleaned and degreased.

A layer of zinc coating is applied through a hot-dip galvanizing process.

Primer coating and color coating are applied on both sides.

The coil is baked and cooled, resulting in a glossy, durable surface finish.

1.3 Key Features of PPGI

- Excellent corrosion resistance due to zinc protection.

- Wide range of colors and finishes for aesthetic applications.

- Easy to form, bend, and fabricate for roofing or wall panels.

- Cost-effective compared to PPGL for indoor and mild outdoor environments.

What is PPGL Coil?

PPGL stands for Pre-Painted Galvalume, a type of steel coil coated with a zinc-aluminum alloy before being painted. The coating consists of 55% aluminum, 43.5% zinc, and 1.5% silicon, also known as Al-Zn coating.

2.1 Composition and Coating

- Base metal: Cold-rolled steel

- Coating layer: 55% aluminum, 43.5% zinc, 1.5% silicon

- Coating weight: Usually 100–150 g/m²

- Paint system: PE, SMP, PVDF, or polyurethane (similar to PPGI)

2.2 Production Process

Cold-rolled steel passes through cleaning and pretreatment stages.

The steel is hot-dip coated in molten aluminum-zinc alloy.

It is chromated to enhance adhesion.

A primer and top coat are applied, followed by baking and coiling.

2.3 Key Features of PPGL

- Outstanding corrosion and heat resistance due to the aluminum content.

- Excellent reflectivity — reflects heat and UV rays effectively.

- Longer lifespan than PPGI in marine and industrial environments.

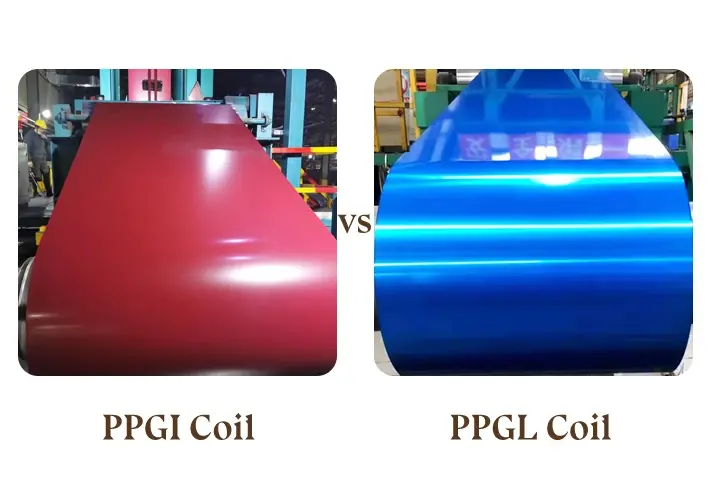

- Smooth and metallic appearance with superior durability.

Chemical and Physical Comparison Between PPGI and PPGL

| Property | PPGI (Pre-Painted Galvanized) | PPGL (Pre-Painted Galvalume) |

|---|---|---|

| Base Metal | Cold Rolled Steel | Cold Rolled Steel |

| Coating Type | 100% Zinc | 55% Aluminum, 43.5% Zinc, 1.5% Silicon |

| Coating Weight | 60–275 g/m² | 100–150 g/m² |

| Corrosion Resistance | Moderate | Excellent |

| Heat Resistance | Up to 200°C | Up to 315°C |

| Surface Finish | Glossy, Smooth | Metallic, Silvery |

| Paint Adhesion | Better on smooth surfaces | Slightly less due to aluminum surface |

| Cost | Lower | Slightly higher |

| Typical Lifespan | 10–15 years | 20–25 years |

Major Differences Between PPGI and PPGL

4.1 Coating Composition

- PPGI uses a pure zinc coating, while PPGL uses a zinc-aluminum alloy.

- The aluminum in PPGL enhances corrosion and oxidation resistance, especially in humid or coastal regions.

4.2 Corrosion Resistance

- Zinc forms a sacrificial layer that protects steel from rust, but it corrodes faster in salty or acidic environments.

- Aluminum in PPGL forms a protective oxide layer, providing 3–6 times higher corrosion resistance than PPGI.

4.3 Appearance and Color Retention

- PPGI offers more vivid and glossy colors, ideal for decorative purposes.

- PPGL provides a metallic and matte look, which is preferred for industrial and architectural uses.

4.4 Heat and UV Resistance

- PPGL has better heat reflectivity, reducing temperature buildup on roofing sheets.

- It also resists UV degradation more effectively than PPGI, ensuring color stability.

4.5 Service Life

- PPGI typically lasts 10–15 years under normal conditions.

- PPGL can last 20–25 years or more, depending on the environment and coating thickness.

Applications of PPGI Coils

Due to their affordability and attractive appearance, PPGI coils are widely used in both residential and commercial sectors.

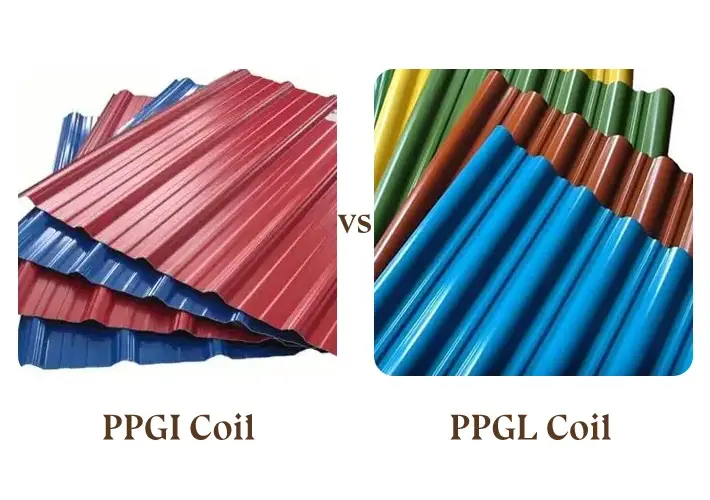

5.1 Roofing and Wall Panels

PPGI sheets are commonly used for residential roofing, industrial sheds, and warehouse walls. The zinc coating ensures adequate rust protection in mild environments.

5.2 Home Appliances

Used in the outer shells of refrigerators, washing machines, air conditioners, and other household appliances due to their bright, decorative finishes.

5.3 Interior Decoration

The wide color range of PPGI makes it ideal for ceiling panels, partition boards, and interior wall panels.

5.4 Automotive and Transport

PPGI steel is used in automotive bodies, trailers, and containers where lightweight and cost-effective materials are essential.

Applications of PPGL Coils

PPGL coils are preferred for projects requiring high performance in corrosive or high-temperature environments.

6.1 Industrial and Commercial Roofing

PPGL is the top choice for factories, power plants, warehouses, and marine buildings, where high corrosion resistance is required.

6.2 Pre-Engineered Buildings (PEBs)

Its long life and reflective surface make it suitable for PEB structures and prefabricated buildings.

6.3 Solar Panel Mounting and HVAC Systems

Due to high heat reflectivity and thermal stability, PPGL is often used for solar panel mounting structures and air-conditioning ducting.

6.4 Agricultural Sheds and Greenhouses

PPGL panels can withstand humidity and chemical exposure, making them ideal for animal farms, greenhouses, and fertilizer plants.

How to Choose Between PPGI and PPGL?

Selecting between PPGI and PPGL depends on project conditions, budget, and performance expectations.

| Condition | Recommended Material |

|---|---|

| Indoor applications | PPGI |

| Budget-sensitive projects | PPGI |

| Coastal or humid regions | PPGL |

| High heat exposure | PPGL |

| Long-term industrial use | PPGL |

| Aesthetic indoor design | PPGI |

In short:

- If your project requires color variety and cost-efficiency, go for PPGI.

- If your project demands long-term corrosion protection, PPGL is the better investment.

Global Market Trends of PPGI and PPGL

The global color-coated steel coil market has been steadily growing due to the expansion of the construction, automotive, and appliance sectors.

- Asia-Pacific region, especially China, India, and Vietnam, dominates the production and export of PPGI and PPGL coils.

- In 2024, the global market size for color-coated coils was valued at over USD 25 billion, with an expected CAGR of 6–8% through 2030.

- China remains the largest manufacturer and exporter, supplying a wide range of thicknesses (0.12–1.2 mm) and widths (600–1250 mm) to markets in Africa, South America, and the Middle East.

Why Choose a Reliable Chinese Supplier

When sourcing PPGI or PPGL coils, choosing a trusted manufacturer in China ensures:

- High-quality galvanized and galvalume base coils

- Advanced color coating lines

- Strict quality control (ISO, SGS, BV certified)

- Customized coil sizes, colors, and surface finishes

- Competitive factory-direct prices

As a leading PPGI & PPGL coil supplier in China, we provide:

- Coil thickness: 0.12–1.2 mm

- Coil width: 600–1250 mm

- Coating thickness: Z60–Z275 / AZ70–AZ150

- Paint thickness: Top 10–25 μm, Back 5–10 μm

- Coil weight: 3–6 tons

Our products are widely used in roofing systems, wall cladding, and pre-engineered buildings across more than 50 countries.

Conclusion

Both PPGI and PPGL coils play vital roles in modern construction and industrial manufacturing.

- PPGI provides affordability and color flexibility, making it ideal for interior decoration, home appliances, and general roofing.

- PPGL, on the other hand, offers superior corrosion and heat resistance, suitable for coastal, industrial, and high-temperature applications.

When selecting between the two, understanding their coating composition, performance characteristics, and cost differences is essential to make the right choice for your project.

If you’re looking for high-quality PPGI and PPGL coils directly from a Chinese factory, feel free to contact us for specifications, samples, and pricing.

We ensure consistent quality, fast delivery, and customized solutions to meet your business needs.