Square steel tubes are among the most widely used structural steel products in modern construction, manufacturing, and engineering. Known for their excellent strength, uniform shape, and versatile applications, they are ideal for both structural and decorative purposes. Understanding the common sizes and thicknesses of square steel tubes is essential for selecting the right material for your project — whether it’s a building framework, machinery support, furniture frame, or transport equipment.

This article provides a comprehensive overview of square steel tube dimensions, wall thicknesses, production standards, material grades, and applications to help you make an informed purchasing decision.

What Is a Square Steel Tube?

A square steel tube, also known as a hollow structural section (HSS), is a steel product with a square cross-section and a hollow core. It is made by forming and welding a flat steel strip or by seamless hot rolling.

These tubes are typically made from carbon steel, galvanized steel, stainless steel, or alloy steel, depending on the application requirements. The uniform cross-section ensures even load distribution and high resistance to torsion, compression, and bending forces.

Key features include:

- High strength-to-weight ratio

- Uniform structure

- Easy fabrication (cutting, drilling, welding)

- Corrosion resistance (especially for galvanized or stainless types)

- Smooth surface and clean aesthetic

Standard Sizes of Square Steel Tubes

Square steel tubes come in a wide range of outer diameters (OD) and wall thicknesses (WT) to suit various industries. The dimensions are typically measured in millimeters (mm) or inches (in).

Below are the most common size ranges used globally:

| Outer Diameter (OD) | Wall Thickness (WT) | Approx. Weight (kg/m) | Common Applications |

|---|---|---|---|

| 10 × 10 mm | 0.8 – 1.5 mm | 0.28 – 0.55 | Furniture, lightweight structures |

| 20 × 20 mm | 1.0 – 2.0 mm | 0.56 – 1.10 | Handrails, frames, displays |

| 25 × 25 mm | 1.2 – 3.0 mm | 0.90 – 2.15 | Equipment frames, small supports |

| 30 × 30 mm | 1.5 – 3.5 mm | 1.25 – 2.70 | Machinery frames, doors, windows |

| 40 × 40 mm | 1.8 – 4.0 mm | 1.90 – 3.85 | Structural parts, racks |

| 50 × 50 mm | 2.0 – 5.0 mm | 2.60 – 5.80 | Building columns, gates |

| 60 × 60 mm | 2.5 – 6.0 mm | 3.50 – 7.20 | Industrial frameworks |

| 80 × 80 mm | 3.0 – 8.0 mm | 5.20 – 10.80 | Construction beams, platforms |

| 100 × 100 mm | 4.0 – 10.0 mm | 7.85 – 19.60 | Heavy structures, bridges |

| 120 × 120 mm | 5.0 – 12.0 mm | 11.50 – 27.00 | Building columns, cranes |

| 150 × 150 mm | 6.0 – 16.0 mm | 17.60 – 45.10 | Industrial buildings |

| 200 × 200 mm | 8.0 – 20.0 mm | 31.40 – 78.50 | Large-scale construction |

These are standard commercial sizes; custom sizes can also be produced according to customer requirements.

Wall Thickness Options and Their Uses

The wall thickness of a square tube determines its mechanical strength and weight.

Here’s a general classification:

| Type | Wall Thickness Range | Common Use |

|---|---|---|

| Light Gauge | 0.5 mm – 2.0 mm | Furniture, decorative, low-stress structures |

| Medium Gauge | 2.5 mm – 6.0 mm | General construction, automotive, machinery |

| Heavy Gauge | 6.0 mm – 20.0 mm | Structural columns, bridges, heavy equipment |

Rule of thumb:

- The thicker the wall, the higher the load capacity but also the heavier the weight.

- Engineers balance cost, strength, and weight depending on the project requirements.

International Standards for Square Steel Tubes

Square steel tubes are produced according to different national and international standards to ensure quality, dimensional accuracy, and strength.

Here are the most commonly used standards:

| Standard | Region/Country | Material Type | Typical Grade |

|---|---|---|---|

| ASTM A500 | USA | Cold-formed carbon steel | Grade A, B, C |

| ASTM A513 | USA | Mechanical tubing | Type 1, 2, 5 |

| EN 10210 / EN 10219 | Europe | Hot-finished / Cold-formed | S235, S275, S355 |

| GB/T 6728-2017 | China | Structural steel | Q195, Q235, Q345 |

| JIS G3466 | Japan | Structural carbon steel | STKR400, STKR490 |

| AS/NZS 1163 | Australia | Cold-formed steel | C250, C350, C450 |

These standards define tensile strength, yield strength, chemical composition, and tolerance levels. Buyers should confirm which standard suits their engineering or construction requirements.

Surface Treatments of Square Steel Tubes

The performance and durability of square steel tubes can be greatly enhanced through surface treatments. Common types include:

1.Black Steel (Uncoated)

- As-rolled surface, low cost

- Used for indoor and non-corrosive environments

2.Pre-Galvanized / Hot-Dip Galvanized

- Zinc coating thickness: 40–275 g/m²

- Provides excellent corrosion resistance

- Widely used in outdoor and humid environments

3.Powder Coated / Painted

- Available in multiple colors and finishes

- Aesthetic appeal + rust protection

4.Stainless Steel Polishing

- Mirror finish, brushed finish, matte finish

- For modern architectural and decorative applications

Typical Applications of Square Steel Tubes

Square steel tubes are highly versatile and appear in almost every major industry.

(1) Construction and Infrastructure

- Building columns, beams, and trusses

- Guardrails and handrails

- Staircases, balconies, and fences

(2) Manufacturing and Machinery

- Machine frames and supports

- Conveyor systems

- Vehicle chassis and agricultural equipment

(3) Furniture and Interior Design

- Modern furniture frames

- Display racks and shelving systems

- Office desks, chairs, and partitions

(4) Transportation Industry

- Trailer frames

- Shipbuilding structures

- Railway and metro systems

(5) Renewable Energy

- Solar panel mounting systems

- Wind turbine support structures

(6) Agricultural and Industrial Storage

- Greenhouse frames

- Warehouse racks

- Factory partitions

How to Choose the Right Size and Thickness

When selecting a square steel tube, consider the following key factors:

- Load-Bearing Requirement

- Heavy structures (bridges, warehouses) → ≥ 6 mm wall

- Light furniture or decorative items → 1–2 mm wall

- Length Requirement

- Common lengths: 6 m, 9 m, 12 m

- Custom cutting available upon request

- Material Grade

- For general use: Q235, S235

- For high-strength applications: Q345, S355, or ASTM A500 Grade C

- Corrosion Resistance

- Outdoor projects → galvanized or powder-coated

- Indoor → black steel or painted finish

- Welding and Fabrication

- Choose grades suitable for easy welding and forming

Weight Calculation Formula for Square Steel Tube

For engineers and buyers, it’s useful to calculate the theoretical weight before ordering:

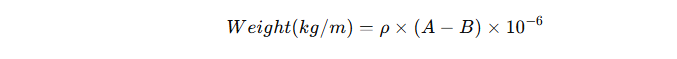

Formula:

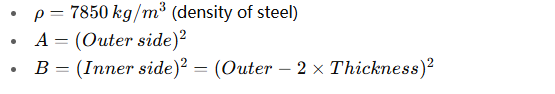

Where:

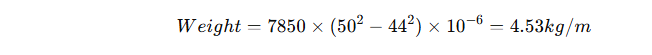

Example:

For 50×50×3 mm tube:

This helps estimate shipment weight and project cost accurately.

Global Market Trends for Square Steel Tubes

According to industry data, the global demand for hollow structural sections (HSS) including square steel tubes has been steadily increasing, particularly in:

- Asia-Pacific (China, India, Vietnam): Rapid infrastructure development

- North America: Sustainable building designs using HSS

- Europe: Emphasis on lightweight, high-strength, recyclable steel

Price range (2025 average):

- Carbon steel tube: $550 – $850 per ton

- Galvanized steel tube: $700 – $1000 per ton

- Stainless steel tube: $1800 – $3500 per ton

Prices fluctuate depending on raw material cost (iron ore, zinc), global demand, and freight costs.

Why Choose a Chinese Square Steel Tube Supplier

China is one of the world’s largest producers and exporters of square steel tubes due to:

- Advanced production technology (ERW, seamless, cold-formed)

- Strict quality control (GB/T, ASTM, EN standards)

- Competitive pricing

- Customization options (cutting, coating, packaging)

As a professional Chinese steel tube manufacturer and exporter, we supply a wide range of sizes and thicknesses for global projects. Our products comply with ASTM, EN, and GB standards and are exported to Europe, the Middle East, and South America.

Conclusion

Understanding the common sizes and thicknesses of square steel tubes is essential for selecting the right product for your structural or industrial needs. From 10×10 mm light tubing to 200×200 mm heavy-duty columns, the wide range of available specifications offers flexibility for any application.

When sourcing from China, you can expect competitive pricing, stable supply, and reliable quality that meet international standards.

Looking for a Reliable Square Steel Tube Supplier?

Contact us today for factory-direct prices, customized specifications, and fast delivery worldwide.

We provide professional support to meet your construction, manufacturing, or export needs.