Introduction

Metal expansion bolts are essential fastening components widely used in construction, industrial assembly, and home improvement projects. Known for their ability to anchor securely into concrete, brick, stone, and other solid materials, these bolts provide strong, durable connections where standard screws or nails may fail. Their design allows them to expand when tightened, creating a secure hold against the base material.

As construction technology continues to evolve, metal expansion bolts have become available in multiple types, each engineered to meet specific performance needs. From heavy-duty structural applications to medium-load fixtures, the range of expansion bolts ensures that builders, engineers, and contractors can choose the right solution for any project.

This article provides a detailed overview of the types of metal expansion bolts and explores their applications in modern construction and industrial use.

What Are Metal Expansion Bolts?

Metal expansion bolts are anchoring devices that use mechanical expansion to fix objects to solid base materials. They typically consist of a bolt, nut, washer, and an expansion sleeve. When the bolt is tightened, the sleeve expands against the walls of the drilled hole, creating friction and pressure that hold the bolt securely in place.

Key Features of Expansion Bolts:

- High load-bearing capacity.

- Corrosion-resistant coatings (zinc, stainless steel, galvanized).

- Suitable for solid materials like concrete, stone, and brick.

- Available in multiple designs for light, medium, and heavy loads.

Types of Metal Expansion Bolts

1.Wedge Anchor Bolts

Wedge anchors are one of the most commonly used expansion bolts. They are designed with a steel sleeve at the end that expands when the bolt is tightened.

Features:

- Made from carbon steel, stainless steel, or galvanized steel.

- Available in a wide range of diameters and lengths.

- Provide strong tension and shear resistance.

Applications:

- Anchoring structural supports.

- Securing heavy machinery.

- Fixing railings, ladders, and steel columns.

- Ideal for concrete surfaces.

2.Sleeve Anchor Bolts

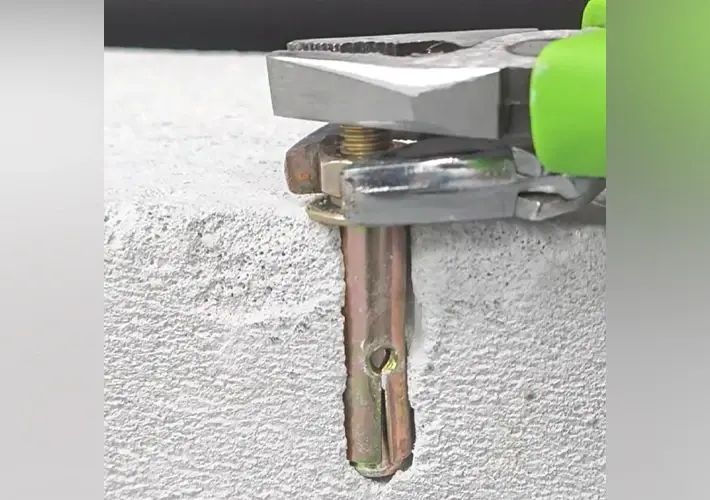

Sleeve anchors consist of a threaded bolt enclosed in a metal sleeve. When tightened, the sleeve expands outward to grip the hole walls.

Features:

- Suitable for medium-duty applications.

- Can be used in brick, block, and concrete.

- Easy to install with standard tools.

Applications:

- Fixing handrails and guardrails.

- Mounting signs and brackets.

- Attaching light to medium fixtures in masonry.

3.Shield Anchor Bolts

Shield anchors have a split metal sleeve that expands in multiple directions when tightened, providing a strong grip.

Features:

- Excellent for irregular or softer masonry.

- High resistance to pull-out forces.

- Available in heavy-duty models.

Applications:

- Fixing heavy equipment to masonry.

- Securing structural beams.

- Ideal for solid and hollow masonry.

4. Drop-In Anchor Bolts

Drop-in anchors are cylindrical expansion anchors installed flush with the surface of the base material.

Features:

- Installed by hammering into a pre-drilled hole.

- Expansion is triggered with a setting tool.

- Flush finish allows surface-level installations.

Applications:

- Overhead fixtures and suspended ceilings.

- HVAC systems and ductwork.

- Electrical conduits and pipe supports.

5. Through Bolt Anchors

Through bolts are expansion bolts designed to pass through the fixture and expand within the base material.

Features:

- Provide excellent load capacity.

- Allow for direct fixture installation without pre-positioning.

- Available in hot-dip galvanized or stainless steel.

Applications:

- Bridges and structural steel connections.

- Guardrails and barriers.

- Heavy-duty industrial machinery installations.

6. Nylon-Sleeved Metal Expansion Bolts

These anchors combine a metal bolt with a nylon sleeve, which helps distribute pressure more evenly.

Features:

- Corrosion-resistant with non-metallic sleeve.

- Provides vibration resistance.

- Designed for medium loads.

Applications:

- Light structural connections.

- Electrical boxes and fixtures.

- Indoor installations where corrosion resistance is essential.

7. Heavy-Duty Expansion Anchors

These are specialized anchors designed for maximum load-bearing capacity in demanding applications.

Features:

- Constructed from high-strength steel.

- Tested for seismic and dynamic loads.

- Suitable for cracked and uncracked concrete.

Applications:

- Bridges, tunnels, and highways.

- High-rise building construction.

- Industrial machinery and equipment foundations.

8. Bolt with Expansion Cone (Rawl Bolts)

These traditional expansion bolts feature a cone-shaped insert that expands the outer sleeve.

Features:

- Strong and reliable in masonry.

- Easy installation with hand tools.

- Economical compared to other heavy-duty anchors.

Applications:

- Mounting gates and doors.

- Attaching outdoor signage.

- Heavy shelving and racking systems.

Applications of Metal Expansion Bolts

Metal expansion bolts are indispensable across multiple industries. Below are the primary sectors and applications:

1. Construction Industry

- Fixing structural steel beams.

- Anchoring columns and trusses.

- Installing scaffolding supports.

- Mounting safety barriers.

2. Industrial Applications

- Securing heavy machinery and equipment.

- Anchoring conveyor systems.

- Mounting storage racks and shelving.

- Fixing pipelines and ducting systems.

3. Residential and Commercial Buildings

- Installing handrails, guardrails, and staircases.

- Fixing furniture, cabinets, and fixtures.

- Hanging air-conditioning units and ceiling fans.

- Mounting electrical panels and lighting.

4. Infrastructure Projects

- Bridges and highway guardrails.

- Railway systems and track supports.

- Tunnels and underground facilities.

- Dams and power plants.

Factors to Consider When Choosing Expansion Bolts

- Base Material: Concrete, brick, or stone requires different anchor types.

- Load Capacity: Heavy machinery requires wedge or through bolts, while light fixtures may only need sleeve anchors.

- Environmental Conditions: Stainless steel or galvanized bolts for outdoor and corrosive environments.

- Installation Requirements: Drop-in anchors for flush surfaces, shield anchors for hollow masonry.

Advantages of Metal Expansion Bolts

- High strength and durability.

- Versatile across multiple applications.

- Resistant to vibration and pull-out forces.

- Available in corrosion-resistant coatings.

- Easy installation with standard tools.

Conclusion

Metal expansion bolts are critical fastening solutions that ensure stability, durability, and safety in a wide range of projects. From light fixtures in residential buildings to heavy machinery in industrial plants, these bolts provide unmatched versatility and reliability.

Understanding the types of expansion bolts—including wedge anchors, sleeve anchors, drop-in anchors, through bolts, and shield anchors—allows contractors and engineers to select the best anchor for their specific application.

As infrastructure and industrial projects continue to expand globally, the demand for high-quality metal expansion bolts is expected to grow. Choosing the right bolt not only improves project efficiency but also ensures long-term structural safety.