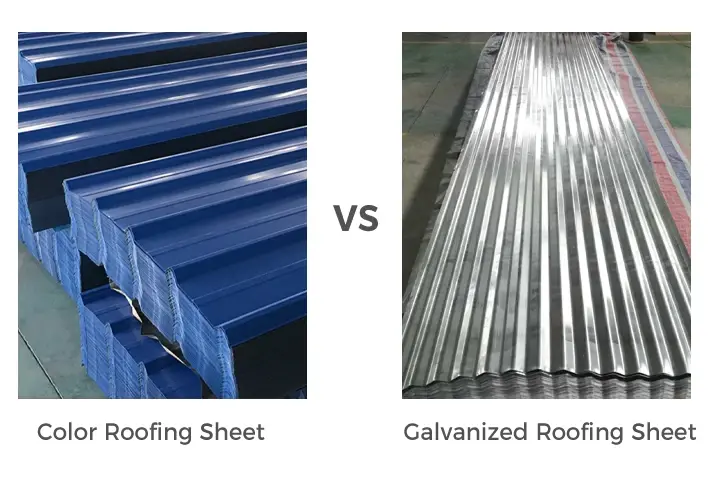

In the modern construction industry, roofing materials play a decisive role in both structural safety and architectural aesthetics. Among the most widely used roofing solutions are color roofing sheets and galvanized roofing sheets. Both have unique advantages, performance characteristics, and applications, making them highly popular in residential, commercial, and industrial projects worldwide.

This article will provide a comprehensive comparison between the two materials, analyzing their composition, durability, cost-effectiveness, installation process, environmental impact, and applications. By the end, you will have a clear idea of which roofing material best suits your project needs.

What is a Color Roofing Sheet?

Color roofing sheets are metal sheets coated with a protective layer of paint or other finishes, such as polyester, PVDF (Polyvinylidene Fluoride), or epoxy. These sheets are generally made from galvanized steel, galvalume, or aluminum, with the addition of color coating for enhanced aesthetics and performance.

Key Characteristics of Color Roofing Sheets:

- Base Material: Often cold-rolled steel, galvanized steel, or aluminum.

- Surface Coating: Painted or pre-painted with advanced coatings.

- Thickness: Typically ranges from 0.3 mm to 0.8 mm.

- Appearance: Available in various colors, patterns, and designs (e.g., matte, glossy, wood grain).

- Standards: Manufactured as per ASTM, JIS, EN, or IS standards depending on export/import market.

What is a Galvanized Roofing Sheet?

Galvanized roofing sheets are produced by applying a zinc coating to a steel base using the hot-dip galvanization process. The zinc layer acts as a protective barrier against corrosion and rust.

Key Characteristics of Galvanized Roofing Sheets:

- Base Material: Mild steel or carbon steel.

- Surface Coating: Zinc (typically 60–275 g/m²).

- Thickness: Usually 0.15 mm to 1.2 mm.

- Appearance: Silver-gray metallic finish, sometimes spangled.

- Standards: Commonly produced under ASTM A653, JIS G3302, or IS 277 standards.

Durability and Corrosion Resistance

Color Roofing Sheet:

- Offers dual protection — zinc/galvalume base for corrosion resistance plus color coating for UV protection.

- Life span: 20–40 years, depending on coating quality.

- Resistant to scratches, fading, and weathering.

Galvanized Roofing Sheet:

- Zinc coating provides a sacrificial layer that protects steel from rust.

- Life span: 10–25 years, depending on zinc thickness and environmental exposure.

- Vulnerable to scratches; once zinc coating is damaged, rust can spread quickly.

Verdict: Color-coated sheets generally last longer and offer better protection in harsh climates.

Aesthetic Appeal

Color Roofing Sheet:

- Wide variety of colors, textures, and finishes.

- Suitable for residential and commercial buildings where appearance matters.

- Can match architectural themes and corporate branding.

Galvanized Roofing Sheet:

- Limited to silver-gray metallic look.

- More suited for industrial or rural applications where aesthetics are less important.

Verdict: Color roofing sheets are superior in aesthetics and design flexibility.

Strength and Load-Bearing Capacity

Both types are made of steel base materials, meaning they are structurally strong. However:

Color Roofing Sheet:

- Coating and finishing add to sheet rigidity.

- Available in corrugated and trapezoidal designs for improved load-bearing capacity.

Galvanized Roofing Sheet:

- Also strong, especially in corrugated form.

- More prone to wear and tear due to coating limitations.

Verdict: Both are structurally strong, but color sheets have the edge in long-term performance.

Cost Comparison

Color Roofing Sheet:

- Initial cost is higher due to additional coating and finishing.

- Reduced maintenance cost due to long lifespan.

- Ideal for projects with long-term value.

Galvanized Roofing Sheet:

- Lower initial cost.

- Higher long-term expenses due to frequent maintenance, repainting, or replacement.

- More suitable for budget-sensitive projects.

Verdict: Galvanized sheets are cheaper upfront, but color roofing sheets offer better long-term value.

Thermal and Acoustic Performance

Color Roofing Sheet:

- Reflective coatings reduce heat absorption.

- Keeps interiors cooler, lowering air-conditioning costs.

- Can be combined with insulation for soundproofing.

Galvanized Roofing Sheet:

- Basic zinc coating does not reflect heat effectively.

- May result in higher indoor temperatures in hot climates.

- Noise during rainfall is higher compared to coated sheets.

Verdict: Color-coated sheets perform better in thermal and acoustic insulation.

Environmental Impact

Color Roofing Sheet:

- Recyclable and energy-efficient due to reflective coatings.

- Longer lifespan reduces material waste.

- Eco-friendly coatings (PVDF, SMP) are increasingly used.

Galvanized Roofing Sheet:

- Also recyclable.

- Shorter lifespan means higher replacement frequency and more waste.

Verdict: Color-coated sheets are more sustainable for long-term projects.

Applications

Color Roofing Sheet:

- Residential houses and villas.

- Commercial complexes, shopping malls, and offices.

- Warehouses with corporate branding.

- Schools, hospitals, and community centers.

Galvanized Roofing Sheet:

- Industrial sheds and factories.

- Agricultural buildings like barns and storage units.

- Rural housing and low-cost housing projects.

- Temporary structures and shelters.

Global Market Trends

Color Roofing Sheet Market:

- Growing demand in Asia-Pacific, Africa, and Middle East for urban and residential projects.

- Estimated CAGR: >6% from 2024–2030.

- Increasing popularity in developed countries due to aesthetics + durability.

Galvanized Roofing Sheet Market:

- Still widely used in developing economies due to affordability.

- Growth is slower compared to color-coated sheets.

- Expected CAGR: ~3% from 2024–2030.

Which to Choose?

The choice between color roofing sheets and galvanized roofing sheets depends on budget, project type, and desired lifespan:

Choose Color Roofing Sheet if:

- You want long-lasting roofing with low maintenance.

- Aesthetic appeal is important.

- Project is residential, commercial, or high-value industrial.

Choose Galvanized Roofing Sheet if:

- You are working with a limited budget.

- Roofing is for temporary or rural structures.

- Aesthetics are not a priority.

Conclusion

Both color roofing sheets and galvanized roofing sheets have their advantages, but in terms of durability, energy efficiency, aesthetics, and long-term cost savings, color roofing sheets are the preferred choice for most modern construction projects.

Galvanized roofing sheets still hold value in low-cost and temporary applications, but as architectural preferences evolve, color-coated sheets are increasingly becoming the global standard.

We are a professional roofing materials manufacturer and supplier in China, offering both color-coated roofing sheets and galvanized roofing sheets for international wholesale and export. If you are looking for high-quality, cost-effective roofing solutions, feel free to contact us for customized quotes and technical support.