Galvanized roofing sheets are widely used across residential, commercial, agricultural, and industrial projects due to their strength, corrosion resistance, and cost-effectiveness. However, with various types, thicknesses, coatings, and profiles available in the market, choosing the right galvanized sheet can be challenging, especially for project managers, builders, and importers dealing with large-scale applications.

This guide will provide a comprehensive overview of how to select the most suitable galvanized roofing sheet for your project, whether you’re sourcing for a local construction site or planning bulk imports.

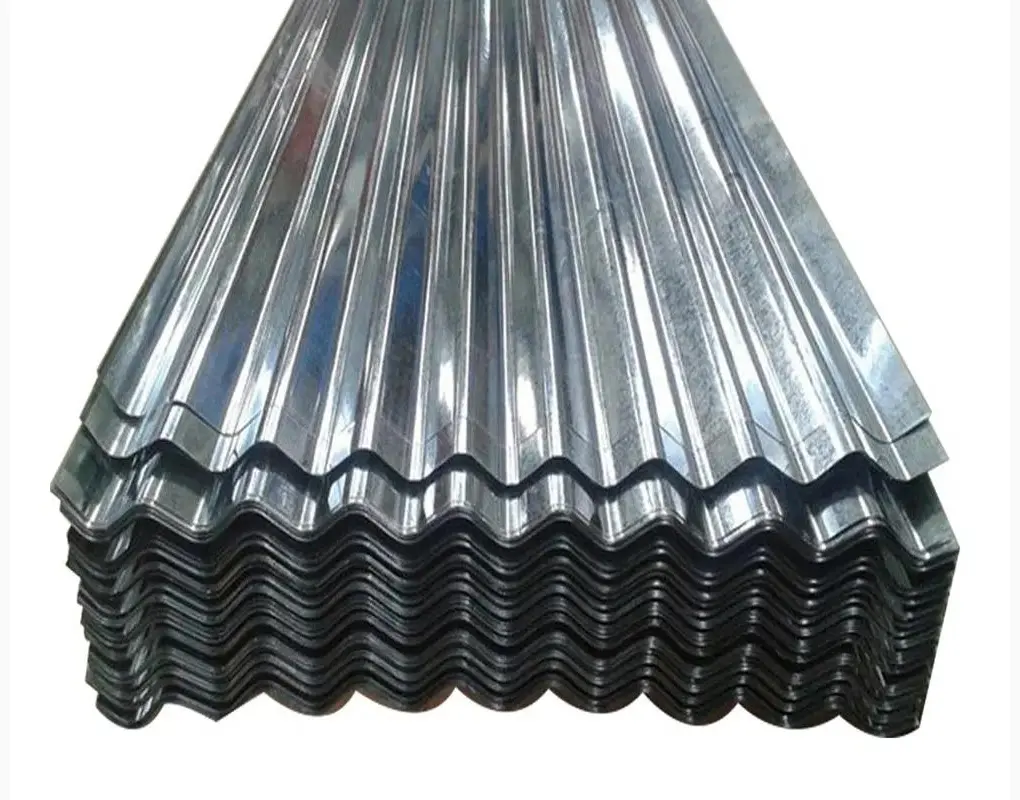

Understanding What Galvanized Roofing Sheets Are

Galvanized roofing sheets are steel sheets coated with a layer of zinc through a galvanization process. The zinc layer protects the steel from corrosion, extending its lifespan even in harsh weather conditions. There are two main galvanizing methods:

- Hot-dip galvanizing: The steel is dipped in molten zinc. It provides a thicker, more durable coating.

- Electro-galvanizing: A thinner zinc layer is applied via electroplating. It offers a smoother finish but less corrosion resistance.

Common profiles include:

- Corrugated

- IBR (Inverted Box Rib)

- Trapezoidal

- Standing seam

Why Galvanized Roofing Sheets Are Popular

Galvanized steel roofing sheets offer several benefits:

- Corrosion resistance: The zinc coating protects against rust and harsh environmental conditions.

- Long service life: With proper maintenance, galvanized sheets can last 20–50 years.

- High strength-to-weight ratio: Ideal for large-span roofing without heavy structural support.

- Low maintenance cost: No frequent repainting or sealing required.

- Eco-friendly: Fully recyclable at the end of life.

Key Factors to Consider When Choosing

When selecting the right galvanized sheet, consider the following technical and functional factors:

a) Zinc Coating Thickness (Zinc Mass or Z Rating)

Zinc coating is measured in grams per square meter (g/m²). Common grades include:

- Z100–Z275 for residential/light commercial use.

- Z350–Z600 for heavy-duty or marine environments.

The thicker the coating, the better the corrosion resistance. For example:

- Z275 = 275 g/m² of zinc (137.5 g/m² on each side)

Recommendation: For coastal or humid regions, opt for Z350 or above.

b) Base Steel Thickness

Measured in millimeters (mm) or gauge, common thicknesses are:

- 0.14–0.25mm for temporary structures

- 0.3–0.5mm for residential

- 0.6–1.2mm for industrial/commercial

Thicker sheets offer more durability but are heavier and costlier.

Tip: Use thicker sheets for areas with strong winds or snow loads.

c) Surface Finish and Coating Options

Depending on application and appearance, surface treatments include:

- Regular spangle: Visible crystal pattern, decorative.

- Minimized spangle: Smaller crystals, more uniform appearance.

- Zero spangle: Smooth surface, ideal for painting.

Additional coatings:

- Chromated (passivated)

- Oiled (for temporary rust prevention)

- Pre-painted galvanized steel (PPGI)

d) Profile and Rib Design

Profile affects both load-bearing capacity and aesthetic appeal. Choose based on:

- Corrugated profile: Traditional look, good water shedding.

- Trapezoidal/IBR profile: High strength and modern design.

- Standing seam: Best for high-end or leak-proof projects.

Roof pitch and drainage should be matched with the profile type.

Application-Based Recommendations

a) Residential Buildings

- Thickness: 0.3–0.5 mm

- Zinc Coating: Z275

- Profile: Corrugated or trapezoidal

- Optional: Pre-painted for color aesthetics

b) Commercial Warehouses & Factories

- Thickness: 0.5–0.75 mm

- Zinc Coating: Z275–Z350

- Profile: IBR or trapezoidal

- Optional: Insulated roofing panels

c) Agricultural Structures (barns, sheds)

- Thickness: 0.4–0.6 mm

- Zinc Coating: Z275

- Profile: Corrugated

- Optional: Anti-condensation coating on back

d) Coastal or Marine Environments

- Thickness: 0.5–0.75 mm

- Zinc Coating: Z450–Z600

- Profile: Standing seam or heavy-duty trapezoidal

- Optional: Color-coated with marine-grade paint

Factory Strength and Quality Standards

Whether you’re sourcing from a local manufacturer or importing from China, ensure the supplier meets the following standards:

- ISO 9001 certified

- ASTM A653 / JIS G3302 / EN 10346 compliant

- In-house testing: salt spray test, bend test, tensile strength test

- Clear marking of steel grade and zinc coating on coils

Tip for importers: Ask for a Mill Test Certificate (MTC) and third-party inspection report.

Packaging and Transportation

Proper packaging ensures the sheets arrive in excellent condition:

- Waterproof wrapping with PE film

- Edge protectors and steel band strapping

- Palletized or bulk in containers (for exports)

Shipping tips:

- Use 20GP containers for smaller coils or pre-cut sheets

- Use 40GP for larger volumes

- Ensure the supplier understands anti-rust export packaging requirements

Customization Options

Leading factories offer custom services:

- Coil to sheet cutting

- Custom lengths and widths

- Punching or perforation

- Embossed or matte surfaces

- Color coatings (RAL color codes)

These allow you to meet specific market needs or architectural designs.

Cost Factors to Consider

Prices of galvanized roofing sheets depend on:

- Steel base price (influenced by global markets)

- Zinc coating thickness

- Sheet thickness and profile

- Surface coating (painted or non-painted)

- Packaging and transportation

Typical FOB China price range (as of 2025):

| Type | Thickness | Zinc Coating | Price (USD/ton) |

|---|---|---|---|

| Regular Galvanized Sheet | 0.3 mm | Z120 | $550–$650 |

| High-Zinc Roofing Sheet | 0.5 mm | Z275 | $680–$750 |

| Color-Coated Galvanized Sheet | 0.5 mm | Z275 | $800–$950 |

Note: Prices may fluctuate due to steel raw materials and global demand.

Common Mistakes to Avoid

- Underspecifying thickness: Leads to deformation or leaks

- Ignoring coating needs: Lower zinc may rust quickly in humid areas

- Wrong profile selection: May cause poor water drainage

- Low-quality sourcing: Leads to product failure and warranty issues

- No local standards compliance: Could delay approvals and installation

Conclusion

Choosing the right galvanized roofing sheet requires a balance of performance, durability, aesthetics, and cost-effectiveness. Whether you are a builder working on a residential project or a B2B buyer looking to import galvanized sheets in bulk, a deep understanding of coating thickness, material strength, profiles, and environmental conditions will ensure you make the best choice for your project.

If you’re seeking a reliable galvanized roofing sheet manufacturer in China, our factory offers:

- Customized production

- Competitive bulk pricing

- Strict quality control

- International certifications

- Flexible export support

Contact us today for free samples, catalogs, or a detailed quote tailored to your project needs.