Aluminum color-coated coils refer to aluminum coils that have undergone a coating process to apply a layer of color onto their surface. This process is commonly used to enhance the aesthetics, durability, and corrosion resistance of aluminum coils, making them suitable for various applications, particularly in construction and manufacturing.

Here’s a brief overview of the key aspects of aluminum color-coated coils:

- Base Material:

- Aluminum Alloy: The base material is typically aluminum or an aluminum alloy. Aluminum is chosen for its lightweight nature, corrosion resistance, and malleability.

- Coating Process:

- Pre-treatment: The aluminum surface is pre-treated to ensure proper adhesion of the coating. This may involve cleaning, chemical treatment, and the application of a primer.

- Coating Application: The coating is applied to the aluminum surface using techniques such as coil coating, where a continuous process is used to apply the coating uniformly.

- Curing: After the coating is applied, the coils are subjected to a curing process to ensure the coating adheres properly and provides the desired properties.

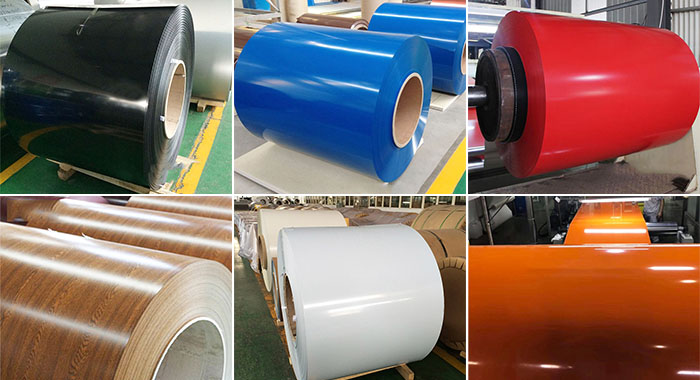

- Color Options:

- Aluminum color-coated coils are available in a wide range of colors, allowing for customization based on the specific requirements and aesthetic preferences of the end-users.

- Applications:

- Construction: These coils are commonly used in the construction industry for roofing, cladding, and facades due to their durability and aesthetic appeal.

- Transportation: They may be used in the manufacturing of vehicles and transportation-related components.

- Appliances: Aluminum color-coated coils can also be applied in the production of appliances, such as refrigerators and air conditioners.

- Benefits:

- Aesthetic Appeal: The color-coating enhances the visual appeal of the aluminum surface, providing a wide range of design possibilities.

- Durability: The coating enhances the durability and weather resistance of aluminum, making it suitable for outdoor applications.

- Corrosion Resistance: Aluminum is naturally corrosion-resistant, and the coating further enhances this property.

- Quality Standards:

- Various industry standards and specifications may govern the manufacturing and quality control processes of aluminum color-coated coils. Compliance with these standards ensures the reliability and performance of the coated aluminum.

It’s essential to consult with manufacturers or suppliers for specific details regarding the composition, coating process, and available color options when considering aluminum color-coated coils for a particular application.