Introduction

Common nails are among the most frequently used fasteners in the construction and woodworking industries. Despite their simple appearance, they play an indispensable role in connecting wood structures, framing houses, building furniture, and supporting countless structural applications. The quality, material, coating, and strength of common nails directly affect the stability and longevity of any project.

This complete guide explores what common nails are, their materials, manufacturing process, coatings, and mechanical strength, and provides detailed insights to help contractors, wholesalers, and construction professionals choose the right nail type for every job.

Whether you are a hardware distributor, construction materials importer, or engineering contractor, understanding these details will help you make better sourcing and quality decisions.

What Are Common Nails?

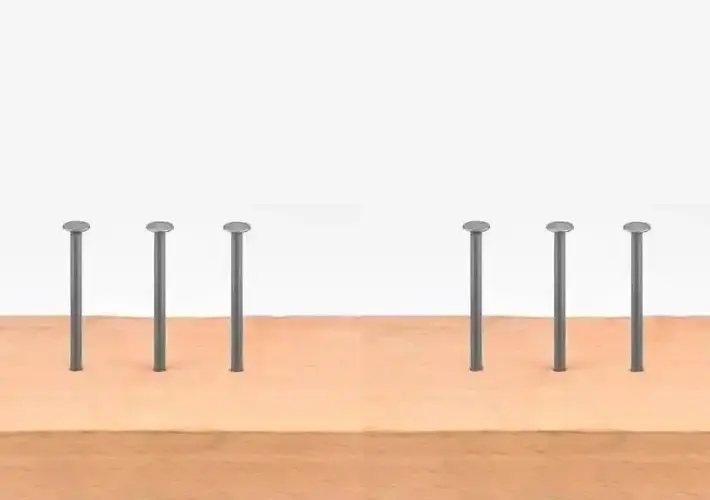

Common nails are a type of round-shank nail characterized by a large, flat head and thick shank. They are primarily used for framing and structural connections in wood construction. Compared with finishing or brad nails, common nails offer greater holding power but leave more visible heads after installation.

Key Characteristics

- Head: Large, flat head for firm hammering and better grip.

- Shank: Thick, round shank designed for strength and resistance to bending.

- Point: Sharp diamond point for easy penetration into dense wood.

- Length: Typically ranges from 1 inch (2.5 cm) to 6 inches (15 cm).

- Diameter: Ranges from 2d to 60d sizes, with “d” referring to “penny” — a traditional nail size measurement.

Common Applications

- Wooden frame structures

- Furniture assembly

- Wooden crates and pallets

- Subfloor and decking installations

- General carpentry and woodworking

Common nails are also used in temporary constructions, where the strength of connection is crucial, but aesthetic concerns are minimal.

Materials Used in Common Nails

The performance and price of common nails depend heavily on their base material. Different materials offer distinct advantages in corrosion resistance, mechanical strength, and cost-effectiveness.

(1) Low-Carbon Steel (Mild Steel)

- Most common material for manufacturing nails.

- Offers excellent tensile strength and cost efficiency.

- Suitable for general indoor and non-corrosive environments.

- Can be coated (e.g., galvanized or black oxide) to enhance corrosion resistance.

Pros:

- Inexpensive

- Easy to manufacture

- High strength-to-cost ratio

Cons:

- Prone to rust in humid or outdoor conditions unless coated

(2) High-Carbon Steel

- Contains higher carbon content (0.6–1.0%).

- Provides superior strength and hardness, ideal for structural and industrial applications.

- Used when high pull-out strength and impact resistance are required.

Applications: Framing, concrete nailing, and hardwood assembly.

(3) Stainless Steel

- Resistant to rust and corrosion even in harsh weather conditions.

- Common grades: AISI 304, 316, and 410.

- Ideal for outdoor projects, marine environments, and high-humidity areas.

Advantages:

- Long service life

- High corrosion resistance

- Suitable for exterior wooden structures, docks, and roofing

Disadvantages:

- Higher cost

- Slightly softer than carbon steel in certain grades

(4) Copper

Rarely used for heavy-duty applications but ideal for decorative work or electrical installations due to conductivity and aesthetic color.

Naturally corrosion-resistant.

(5) Aluminum

Lightweight and corrosion-resistant, but lower in strength.

Typically used for softwood or non-load-bearing applications.

Manufacturing Process of Common Nails

The process of making common nails involves several precise stages to ensure consistent quality and strength.

Step 1: Wire Drawing

Steel rods are drawn through a series of dies to reduce the diameter to the required nail thickness.

Step 2: Cutting

The drawn wire is automatically cut into predetermined lengths corresponding to the desired nail sizes (e.g., 2d to 60d).

Step 3: Head Forming

One end of the wire is flattened under a press to form the nail head. The head ensures proper hammer contact and prevents pull-through.

Step 4: Point Forming

The opposite end is sharpened into a diamond-shaped point, allowing the nail to penetrate wood easily without splitting it.

Step 5: Surface Coating

Depending on the intended application, the nails undergo surface treatments such as galvanizing, polishing, or coloring for corrosion resistance.

Step 6: Heat Treatment (Optional)

For high-strength nails, the material is heat-treated and tempered to improve hardness and tensile strength.

Step 7: Packaging

Nails are sorted, weighed, and packed in boxes or bulk bags, ready for distribution to hardware stores or construction suppliers.

Common Nail Coatings and Finishes

The coating or surface finish of a common nail is critical to its performance, especially in outdoor or humid environments.

(1) Bright (Uncoated) Nails

- Made from plain steel without any coating.

- Suitable for indoor or dry conditions.

- Cheapest option, but rusts easily when exposed to moisture.

(2) Galvanized Nails

Coated with a layer of zinc through either:

- Electro-galvanizing: Smooth and shiny surface, thinner coating.

- Hot-dip galvanizing: Thicker coating, rougher appearance, better corrosion resistance.

Ideal for outdoor projects such as fences, decks, and roofing.

Zinc Layer Thickness:

- Electro-galvanized: 8–12 µm

- Hot-dip galvanized: 40–100 µm

(3) Black Oxide or Bluing

- Provides a decorative dark finish.

- Limited corrosion protection, suitable for interior applications only.

(4) Cement-Coated (Resin-Coated) Nails

- Have a thin resin coating that melts during driving, increasing friction and holding power.

- Widely used in framing and subfloor installations.

(5) Vinyl-Coated Nails

- Yellowish coating that enhances driving efficiency and prevents bending.

- Also increases resistance to pull-out under tension.

(6) Stainless Steel Finish

- No additional coating required due to natural corrosion resistance.

- Maintains shiny silver appearance even after years of outdoor exposure.

Common Nail Sizes and Specifications

Common nails are identified by the traditional penny size (d) system. Each “penny” corresponds to a specific length and gauge.

| Penny Size (d) | Length (inch) | Length (mm) | Shank Diameter (inch) | Typical Use |

|---|---|---|---|---|

| 2d | 1 | 25 | 0.072 | Small woodworking |

| 4d | 1.5 | 38 | 0.080 | Trim and molding |

| 6d | 2 | 50 | 0.099 | Light framing |

| 8d | 2.5 | 64 | 0.131 | General framing |

| 10d | 3 | 76 | 0.148 | Heavy framing |

| 12d | 3.25 | 83 | 0.148 | Subflooring |

| 16d | 3.5 | 89 | 0.162 | Framing and beams |

| 20d | 4 | 102 | 0.192 | Structural connections |

| 60d | 6 | 152 | 0.283 | Heavy timber construction |

Note: For most residential framing work, 8d and 16d common nails are the most frequently used sizes.

Mechanical Strength and Performance

The strength of a common nail depends on both material composition and diameter. The key performance indicators include:

(1) Tensile Strength

- Mild steel nails: 380–550 MPa

- High-carbon steel nails: 700–900 MPa

- Stainless steel nails: 500–750 MPa

(2) Shear Strength

This defines the nail’s resistance to breaking when a lateral force is applied.

For an 8d common nail:

- Average shear strength ≈ 1200–1400 N

(3) Pull-Out Resistance

The resistance to being pulled out from wood depends on:

- Nail diameter

- Length of penetration

- Wood density

- Surface coating (cement-coated nails have 20–40% higher pull-out strength)

(4) Bending Strength

High-carbon steel nails and resin-coated nails resist bending better during hammering or pneumatic installation.

Choosing the Right Common Nail

When selecting the ideal common nail for your project, consider these four main factors:

(1) Application Environment

- Indoor Dry Areas → Bright or vinyl-coated nails

- Outdoor or Moist Areas → Hot-dip galvanized or stainless steel nails

- Marine or Coastal Areas → AISI 316 stainless steel nails

(2) Wood Type

- Softwood (Pine, Fir) → Low-carbon steel nails

- Hardwood (Oak, Maple) → High-carbon or resin-coated nails for stronger grip

(3) Load Requirement

- Structural framing → 8d, 10d, or 16d nails

- Decorative or light assembly → 2d–6d nails

(4) Installation Method

- Manual hammering → Large head nails for better control

- Nail guns → Vinyl-coated nails for smoother driving

Global Market and Export Trends

The global market for nails, screws, and fasteners has shown steady growth, driven by the booming construction industry and DIY markets.

(1) Global Demand

According to market data:

- The global nails and fasteners market size exceeded USD 80 billion in 2024.

- Expected CAGR (Compound Annual Growth Rate) from 2025–2030: 4.5%.

- Asia-Pacific, especially China, remains the largest production base.

(2) Leading Exporters

- China

- Vietnam

- India

- Turkey

Among these, China dominates due to:

- Advanced wire drawing technology

- Complete industrial chain

- Competitive labor and material costs

- Strict quality control systems (ISO, CE-certified factories)

Quality Standards and Certifications

To ensure reliability, common nails must comply with international standards:

| Standard | Region | Specification Scope |

|---|---|---|

| ASTM F1667 | USA | Steel nails, spikes, and staples |

| BS EN 10230-1 | UK/EU | Steel nails for construction |

| JIS B 2804 | Japan | Nail dimensions and materials |

| ISO 10666 | Global | Fastener mechanical properties |

Before exporting, manufacturers usually provide:

- Material test reports (MTR)

- Coating thickness certificates

- Load-bearing test results

Why Choose a Chinese Common Nail Manufacturer

China has become a global hub for high-quality nail production.

As a leading Chinese factory, we provide:

- Full-size range from 2d to 60d

- Customized coating and packaging options

- OEM & ODM support for hardware brands

- Competitive prices due to direct factory supply

- Stable export logistics to North America, Europe, and the Middle East

Our nails undergo strict tensile, bending, and coating thickness tests, ensuring durability and reliability in every batch.

Conclusion

Common nails might appear ordinary, but their materials, coatings, and mechanical properties determine how well a structure stands the test of time. From carbon steel to stainless steel, from bright to hot-dip galvanized finishes, every detail impacts performance.

For contractors, distributors, and wholesalers, selecting the right common nail means balancing cost, corrosion resistance, and strength to achieve long-lasting results.

If you’re sourcing high-quality common nails from China, our factory can provide customized solutions, bulk pricing, and timely global delivery.

Contact us today to get a quotation and technical datasheet for your next project!