Choosing the right expansion screws (also known as expansion anchors or expansion bolts) involves considering several factors to ensure they provide secure and reliable anchoring in various materials. These screws are commonly used for attaching fixtures, equipment, or structures to masonry, concrete, or other solid surfaces. Here’s a step-by-step guide to help you choose the appropriate expansion screws for your application:

Part 1: Choose by type

Type of Expansion Screw:

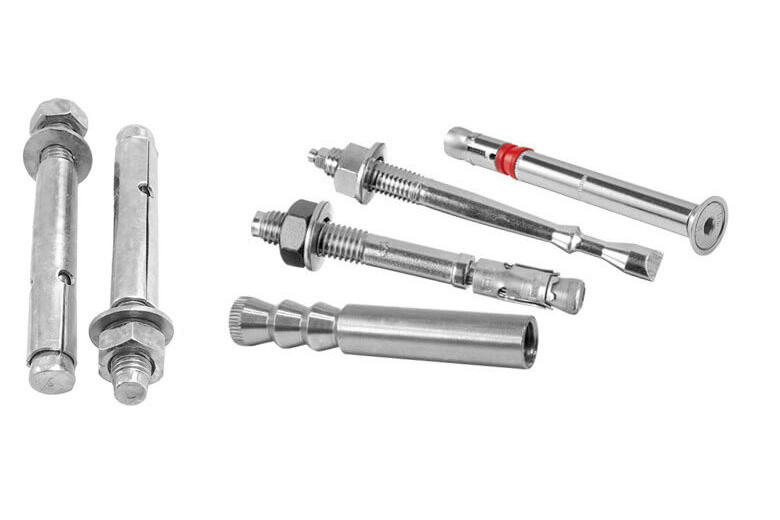

There are different types of expansion screws available, each suited for specific applications:

- Wedge Anchors: Suitable for heavy-duty applications in concrete or masonry.

- Sleeve Anchors: Versatile anchors for a range of materials.

- Drop-In Anchors: Ideal for flush-mounted applications.

- Toggle Bolts: Used for hollow materials like drywall or plaster.

- Lead Anchors: Designed for softer materials like brick or stone.

- Plastic Anchors: Used in lightweight applications in drywall or plaster.

Part 2: Selection according to product characteristics

- Determine the Application: Clearly define the purpose of the expansion screws. Are you mounting something heavy, like a shelf or a structural element, or something lighter, like a picture frame? The weight and load requirements will influence your choice.

- Identify the Material: Know the material you are attaching to (e.g., concrete, masonry, brick, stone, or drywall). Different expansion screws are designed to work better with specific materials.

- Load Capacity: Consider the weight or load the screws will need to support. Most expansion screws will have a load capacity specified in their product details. Ensure the chosen screws can handle the intended load.

- Length and Diameter: The length and diameter of the expansion screw are crucial for proper anchoring. The length should allow for the screw to penetrate the material sufficiently, while the diameter should provide a secure grip. Refer to the manufacturer’s guidelines for recommendations based on your material type and load.

- Installation Depth: Ensure that the chosen screws can be installed at the appropriate depth. Too shallow or too deep insertion can affect the anchor’s holding capacity.

- Environmental Conditions: Consider the environmental factors that may affect the anchor, such as moisture, temperature changes, and corrosive elements. Choose materials that are resistant to rust and corrosion if necessary.

- Installation Process: Make sure you understand the installation process for the chosen expansion screws. Some may require pre-drilling, while others may be self-drilling. Follow the manufacturer’s instructions carefully.

Part 3: Merchant Selection

- Quality and Brand: Opt for expansion screws from reputable brands or manufacturers. Quality screws are more likely to provide a secure and reliable anchor.

- Testing and Consultation: If in doubt, consult with professionals or conduct a small-scale test installation to ensure the chosen expansion screws work as expected before proceeding with a larger installation.

Always follow the manufacturer’s guidelines and recommendations for installation, as improper installation can compromise the anchor’s effectiveness. Remember that safety is paramount, and choosing the right expansion screws will help ensure a stable and secure attachment for your intended application.