Overview: What Are U Nails and How Do They Work

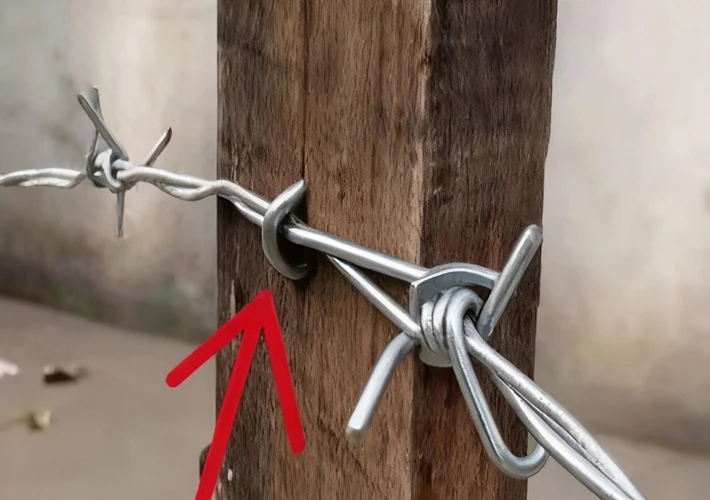

In construction, woodworking, fencing, and agriculture, fasteners play a key role in ensuring stability and safety. Among them, U nails (also known as fencing staples or U-shaped nails) stand out for their simple yet powerful design. Shaped like the letter “U,” these nails are used to clamp materials such as wire mesh, barbed wire, or cables to a wooden surface.

A U nail typically consists of:

- Crown (the curved or flat top) – which straddles the material being fastened.

- Legs (two pointed ends) – which penetrate the base surface, usually wood.

This design gives U nails a strong grip and resistance to pull-out, making them ideal for long-term use in harsh outdoor environments. They can be driven manually with a hammer or installed using pneumatic tools for industrial-scale operations.

Key Characteristics

- U-shaped design provides excellent fastening strength.

- Available in galvanized, stainless steel, and carbon steel options.

- Resistant to loosening under vibration and tension.

- Cost-effective and easy to install.

In short, U nails are an indispensable fastening solution for securing fencing, wiring, and lightweight structures.

Main Types of U Nails and Their Unique Features

U nails are produced in different designs and materials to meet various project needs. Below are the six most common types used across industries:

2.1 Common Round U Nails

These are the standard and most widely used types. They feature a rounded crown that fits snugly over wires or mesh.

- Material: Carbon steel or galvanized steel

- Application: Fixing barbed wire, chain link fences, or garden mesh

2.2 Square U Nails

Square U nails have a flat top instead of a curved one. This shape provides better grip and even pressure on flat materials such as straps or panels.

- Advantages: Better contact area and stability

- Application: Wooden crates, packaging, and furniture fixing

2.3 Barbed U Nails

The legs have small ridges or barbs that improve holding power in wood.

- Advantages: Resistant to pulling out under tension

- Application: Agricultural fencing, high-tension wire installation

2.4 Insulated U Nails

Fitted with a plastic or rubber sleeve, insulated U nails prevent electric current from transferring to wooden surfaces.

- Application: Cable and wire fixing in electrical installations

2.5 Heavy-Duty U Nails

Made from thicker wire (up to 4 mm diameter), these nails are designed for industrial use and high-strength applications.

- Application: Railway sleepers, timber joints, structural connections

2.6 Stainless Steel U Nails

Manufactured from 304 or 316 stainless steel, these nails provide superior corrosion resistance and are ideal for marine or coastal environments.

Common Sizes, Materials, and Surface Treatments

U nails are available in many sizes depending on the wire diameter, leg length, and crown width. Choosing the right size ensures proper grip and long-term stability.

3.1 Standard U Nail Sizes

| Length (mm) | Wire Diameter (mm) | Crown Width (mm) | Typical Application |

|---|---|---|---|

| 12 mm (1/2”) | 1.8–2.0 | 4–6 | Light wire fixing |

| 16 mm (5/8”) | 2.0–2.3 | 5–7 | Small mesh |

| 20 mm (3/4”) | 2.3–2.5 | 6–8 | Fence wire |

| 25 mm (1”) | 2.5–2.8 | 7–9 | Electric fencing |

| 30 mm (1¼”) | 2.8–3.2 | 8–10 | Heavy fencing |

| 40 mm (1½”) | 3.0–3.5 | 9–11 | Structural applications |

3.2 Materials Used

The performance of U nails depends heavily on their base material. Common options include:

- Low Carbon Steel: Cost-effective and easy to produce; ideal for indoor applications.

- Galvanized Steel: Zinc-coated to prevent rust; perfect for outdoor use.

- Stainless Steel (304, 316): High-end option for maximum corrosion resistance.

- Copper-Coated / Aluminum Alloy: Used for aesthetic or lightweight applications.

3.3 Surface Treatments

Surface coating extends the lifespan of U nails by preventing corrosion and improving appearance.

| Coating Type | Benefits | Application Areas |

|---|---|---|

| Bright Finish | Smooth and shiny surface | Indoor woodworking |

| Electro-Galvanized | Moderate rust resistance | Light outdoor use |

| Hot-Dip Galvanized | Thick zinc layer; best protection | Agricultural fencing |

| Vinyl or PVC Coating | Insulated and colored | Cable and wire fixing |

Common Applications of U Nails in Different Industries

U nails are versatile fasteners used across construction, agriculture, and electrical industries. Here are their most common applications:

4.1 Fencing and Agriculture

U nails are indispensable in farm fencing systems. They’re used to attach:

- Barbed wire to wooden posts

- Field fences and mesh panels

- Animal cages or enclosures

4.2 Construction and Woodworking

In construction, U nails secure:

- Reinforcing mesh or metal sheets

- Timber frames

- Safety barriers and panels

Builders prefer galvanized or hot-dip galvanized U nails to ensure long-term durability even under high humidity.

4.3 Electrical Installations

Insulated U nails are widely used to fix cables or wires to walls or ceilings.

- Advantages: Safe installation, tidy appearance, and easy maintenance.

4.4 Furniture and Interior Design

In woodworking and furniture production, smaller U nails or staples are used for:

- Upholstery work

- Backboard fixing

- Decorative panel attachments

4.5 Industrial Packaging

Square-head or heavy-duty U nails are used in wooden crate and pallet manufacturing to ensure secure packaging for export goods.

Manufacturing Process, Quality Control, and Export Packaging

5.1 Manufacturing Process

The production of U nails involves multiple precision steps to ensure strength and consistency:

Wire Drawing: Steel wire is drawn to the required diameter.

Cutting: The wire is cut to the desired length.

Forming: Machines bend the wire into a U shape.

Pointing: Both legs are sharpened for easy penetration.

Surface Treatment: Zinc plating, hot-dip galvanizing, or PVC coating.

Inspection: Dimensional, tensile, and coating quality checks.

Packaging: Products are packed and palletized for export.

5.2 Quality Standards

Reputable manufacturers ensure compliance with:

- ISO 1461 – Hot-dip galvanizing standards

- ASTM A153 / A641 – Zinc coating specifications

- DIN 1151 – Nail manufacturing standards

Each batch undergoes salt spray tests, tensile strength tests, and coating thickness inspection to ensure long-lasting performance.

5.3 Export Packaging

Typical export specifications:

- Packing weight: 20–25 kg per carton or bag

- Palletized packaging for international shipment

- Custom labeling with product specifications and origin

- OEM/ODM available for distributors and wholesalers

China is one of the largest exporters of U nails, supplying to markets across North America, Europe, the Middle East, and Africa.

Choosing the Right U Nail and Future Market Trends

6.1 How to Choose the Right U Nail

Selecting the correct U nail depends on several key factors:

Material Compatibility: Choose galvanized or stainless steel for outdoor projects.

Leg Length: Should be at least double the thickness of the base material.

Coating: Hot-dip galvanized nails for long-term outdoor exposure.

Grip Power: Barbed nails for strong holding capacity.

Installation Tool: Ensure compatibility with manual or pneumatic tools.

6.2 Advantages of U Nails

- High holding power with minimal loosening

- Cost-efficient and easy to install

- Suitable for multiple industries

- Excellent corrosion resistance with proper coating

- Customizable for wholesale and OEM production

6.3 Global Market Trend

The demand for U nails continues to rise due to:

- Expansion of agricultural fencing systems

- Infrastructure development in emerging markets

- Growth in DIY home improvement and packaging sectors

Manufacturers in China lead the global export market thanks to advanced production lines, stable supply capacity, and competitive pricing. Importers can benefit from customized specifications, branding options, and bulk packaging solutions to meet regional market needs.

Conclusion

U nails, though small, play a crucial role in modern construction, fencing, and manufacturing industries. Their U-shaped design, diverse materials, and reliable fastening strength make them one of the most widely used metal fasteners worldwide.

From barbed fencing staples to stainless steel cable fasteners, each type of U nail serves a distinct purpose—ensuring safety, stability, and durability in every project.

For wholesalers and importers, sourcing from an experienced Chinese U nail manufacturer ensures high-quality products, competitive prices, and global export compliance. Whether you’re supplying the construction sector or agricultural markets, U nails remain an essential and profitable fastener solution for your business.