Introduction: What Are FRP Sheets?

Fiber Reinforced Plastic (FRP) sheets are composite materials made by reinforcing a polymer matrix with fibers, typically glass, carbon, or aramid. These materials offer exceptional strength-to-weight ratios, corrosion resistance, durability, and flexibility in design. FRP sheets are commonly used across construction, industrial, and commercial sectors due to their unique performance characteristics.

In recent years, the global demand for FRP materials has grown rapidly, driven by innovations in composite technology and the need for long-lasting, low-maintenance alternatives to traditional building materials like steel, wood, and concrete.

This article explores the wide-ranging applications of FRP sheets in construction, industrial, and commercial projects, highlighting their benefits, typical use cases, and future potential.

I. Applications of FRP Sheets in the Construction Industry

1.1 Structural Reinforcement

FRP sheets are extensively used in retrofitting and strengthening structures, including bridges, tunnels, buildings, and marine infrastructure. Civil engineers use them to reinforce concrete, steel, masonry, and timber structures without adding significant weight.

Key areas:

- Bridge decks and beams

- Columns and beams in buildings

- Parking structures

- Seismic retrofitting in earthquake-prone zones

Benefits:

- High tensile strength and stiffness

- Lightweight, easy to install

- Non-corrosive, especially important in marine and humid environments

- Minimal maintenance cost

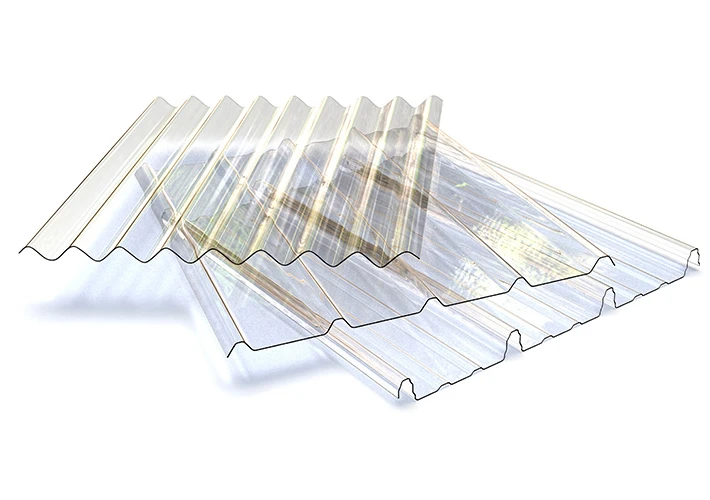

1.2 Roofing and Cladding

FRP roofing sheets are widely used as an alternative to metal or polycarbonate roofing in both commercial and residential buildings. They are UV-resistant, weatherproof, and customizable in terms of color and translucency.

Applications:

- Warehouse roofs

- Skylights and canopies

- Greenhouses

- Sheds and industrial units

Advantages:

- UV protection

- Light transmission control

- Fire retardant options

- Aesthetic flexibility

1.3 Wall Panels and Facades

In modern architecture, FRP wall panels are favored for their sleek finishes and long-lasting durability. These panels are also used in curtain wall systems and external cladding.

Features:

- Excellent thermal insulation

- Weather resistance

- Easy installation on steel or concrete structures

1.4 Sanitary Facilities and Interiors

In commercial construction such as hotels, hospitals, and public buildings, FRP sheets are used for cleanroom walls, toilet partitions, and modular interiors. Their smooth surfaces are resistant to mold, mildew, and chemical agents.

II. Applications of FRP Sheets in Industrial Projects

2.1 Chemical and Petrochemical Plants

FRP sheets provide superior corrosion resistance in harsh chemical environments, making them ideal for use in:

- Chemical tanks and storage vessels

- Flooring in corrosive environments

- Wall linings and ducts in acid or alkali processing areas

Why FRP?

- Long lifespan even under chemical exposure

- Non-conductive and heat-resistant

- Lightweight and easier to install than steel

2.2 Power and Energy Sector

In the power generation and distribution sector, FRP materials are used for:

- Cable trays and protective covers

- Cooling tower panels

- Structural walkways and platforms

Key advantages:

- Non-magnetic and non-conductive properties (important in substations)

- Resistance to high-voltage electrical fields

- Weather and UV durability for outdoor use

2.3 Oil & Gas Industry

FRP sheets offer major advantages in offshore and onshore facilities, especially where salt water, oil, or chemical exposure is common.

Applications:

- Offshore platform decks

- Pipe wrapping and insulation

- Oil refinery interiors

Their resistance to corrosion, high mechanical strength, and low maintenance cost significantly reduce operational downtime.

2.4 Food and Beverage Industry

FRP sheets are commonly used to create hygienic surfaces in food processing plants due to their resistance to bacterial growth, chemicals, and moisture.

Use cases:

- Cleanroom walls and ceilings

- Conveyor covers

- Anti-slip flooring in processing areas

Certifications: Many FRP panels meet FDA or USDA hygiene standards for food-safe environments.

III. Applications of FRP Sheets in Commercial Projects

3.1 Commercial Kitchens and Bathrooms

In commercial kitchens, restaurants, and public restrooms, FRP sheets are popular for their easy-to-clean and mold-resistant surfaces.

Applications:

- Wall and ceiling panels

- Backsplashes and splash guards

- Toilet partitions and shower enclosures

3.2 Retail and Supermarkets

FRP wall panels are used in supermarkets and retail environments for both decorative and functional purposes.

Benefits:

- Aesthetic appeal with various textures and colors

- Impact resistance in high-traffic areas

- Easy maintenance and durability

3.3 Healthcare and Laboratories

Hospitals, clinics, and laboratories require highly sterile and chemical-resistant environments, which FRP panels can provide.

Common installations:

- Operating rooms

- Cleanroom walls and doors

- Isolation areas

Why FRP?

- Seamless installation to reduce bacterial growth

- Resistance to disinfectants and cleaning agents

3.4 Public Infrastructure and Transportation

FRP is used in train stations, airports, bus depots, and public restrooms for interior wall cladding, roofing, and partitioning.

Benefits:

- Fire-retardant grades available

- Lightweight reduces structural load

- Easy and quick to replace damaged panels

IV. Advantages of FRP Sheets Across All Applications

| Advantage | Description |

| Corrosion Resistance | Ideal for chemical and marine environments |

| Lightweight | Easier transportation and installation |

| Durability | Long lifespan with minimal maintenance |

| Fire Retardant Options | Suitable for fire safety compliance |

| Design Flexibility | Can be molded, colored, or textured |

| Non-conductive | Safe for use in electrical environments |

| Cost-effective | Lower lifecycle cost compared to metals or wood |

V. Market Outlook and Future Trends

With the rising global focus on sustainability and cost efficiency, FRP sheets are expected to see significant growth in the coming years. According to market research, the global FRP market size is projected to reach over USD 7 billion by 2030, with Asia-Pacific being the fastest-growing region.

Emerging trends:

- Smart composites: Integration with sensors for structural health monitoring

- Eco-friendly resins: Bio-based FRP materials

- Modular construction: FRP as a core component in prefabricated buildings

- Infrastructure rehabilitation: Growing demand for retrofitting bridges, tunnels, and public buildings

VI. Conclusion: Why Choose FRP Sheets?

FRP sheets provide a powerful alternative to traditional construction and industrial materials due to their superior performance in harsh environments, minimal maintenance, and long-term durability.

Whether you’re a construction contractor, industrial engineer, or commercial building designer, incorporating FRP sheets can improve project outcomes, reduce costs, and ensure long-term satisfaction.

If you’re a wholesaler, distributor, or contractor looking for high-quality FRP sheets from a trusted Chinese manufacturer, we can provide customized solutions at competitive prices. Contact us to learn more.