In recent years, stone-coated roofing tiles have become an increasingly popular choice for residential, commercial, and industrial roofing projects around the world. Combining the strength of metal with the aesthetic appeal of traditional roofing materials, stone-coated tiles offer durability, style, and long-term performance.

However, not all stone-coated tiles are created equal. Selecting the right product for your construction project involves a detailed understanding of product quality, material specifications, surface coatings, manufacturing processes, and supplier credibility.

This comprehensive guide will walk you through everything you need to know about how to choose high-quality stone-coated roofing tiles, whether you’re a developer, contractor, architect, or a global importer.

What Are Stone-Coated Roofing Tiles?

Stone-coated roofing tiles are made of galvanized or galvalume steel sheets that are coated with natural stone granules and sealed with acrylic resin. They are designed to mimic the appearance of traditional roofing materials like clay tiles, slate, or asphalt shingles while offering superior strength and longevity.

Basic Structure:

- Base Material: Galvanized steel or galvalume (typically 0.4mm–0.6mm thickness)

- Protective Layers: Anti-corrosion coatings (e.g., zinc-aluminum)

- Adhesive Layer: Acrylic resin

- Stone Chips: Natural basalt or ceramic granules

- Topcoat: UV-resistant transparent glaze

Why Stone-Coated Roofing Tiles Are a Smart Choice

2.1 Durability

High-quality stone-coated tiles can last over 30 to 50 years thanks to corrosion-resistant steel and durable coatings.

2.2 Weather Resistance

These tiles withstand strong winds, heavy rain, hailstorms, and UV radiation without cracking or fading.

2.3 Lightweight

They weigh much less than clay or concrete tiles (about 6–7 kg per square meter), making them suitable for light structures or renovation projects.

2.4 Aesthetics

Stone-coated tiles are available in a variety of profiles such as Roman, Milano, Shake, Shingle, and Classical, with a broad color palette.

2.5 Energy Efficiency

The reflective coating and air gap design improve thermal insulation, reducing energy costs in hot and cold climates.

2.6 Low Maintenance

Unlike other roofing materials, stone-coated metal tiles resist mold, insects, and algae growth.

Key Factors to Consider When Choosing Stone-Coated Roofing Tiles

3.1 Core Material Quality

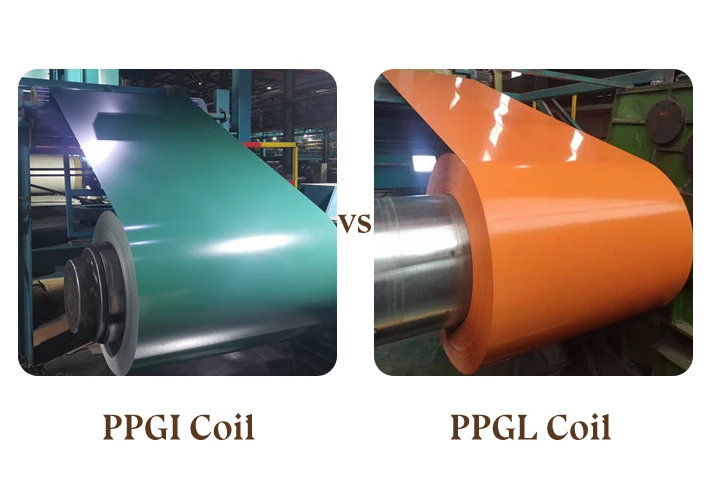

Galvanized Steel (GI) vs. Galvalume Steel (GL)

- Galvalume steel (55% aluminum, 43.5% zinc, 1.5% silicon) offers 3–6 times better corrosion resistance than GI.

- Look for tiles with AZ150/AZ180 coating standards.

3.2 Steel Thickness

- Ideal thickness for roofing tiles: 0.4 mm to 0.5 mm

- Anything thinner than 0.35 mm compromises structural strength

- Ask for mill test certificates (MTC) for verification

3.3 Stone Chips and Coating

Stone Chip Type

- High-quality tiles use natural basalt or ceramic-coated granules that resist UV fading

- Look for uniform granule size and strong adhesion

Acrylic Resin & Topcoat

- Premium tiles use polyurethane or modified acrylic resin that firmly locks granules in place

- A UV-resistant clear coat protects the color and enhances lifespan

3.4 Manufacturing Process

Choose suppliers with:

- Automated coating lines

- Strict quality inspection protocols

- Adherence to ISO9001 or CE standards

- Double baking techniques to improve coating durability

3.5 Certification and Testing

Ensure the tiles meet standards such as:

- ASTM B117 (salt spray resistance)

- EN 14782 (metal roofing standards)

- Fire resistance and wind uplift tests

Common Types of Stone-Coated Roofing Tiles

| Profile Type | Features | Best Use |

|---|---|---|

| Roman | Wavy, traditional Mediterranean style | Villas, luxury homes |

| Milano | Flat and elegant | Modern buildings |

| Classical | Traditional curved profile | Residential homes |

| Shake | Wood-like appearance | Resort-style houses |

| Shingle | Asphalt shingle mimic | American-style buildings |

Each type comes in multiple color options such as charcoal black, terracotta, emerald green, coffee brown, and more.

Common Mistakes to Avoid

5.1 Choosing Based on Price Alone

Low-cost tiles may use poor-quality steel, recycled coatings, or weak adhesives. In the long run, they can fade, corrode, or peel, leading to higher replacement costs.

5.2 Ignoring the Steel Origin

Some suppliers use cheap steel from unknown sources. Choose steel from reliable mills such as Baosteel, POSCO, or BlueScope.

5.3 Not Verifying Coating Standards

Always check:

- Zinc/aluminum coating weight (e.g., AZ150 = 150 g/m²)

- Type and quality of stone granules

- Weather-resistance test results

5.4 Overlooking Packaging and Shipping

Improper packaging can cause chipping or deformation during transport. Look for:

- Edge protectors

- Waterproof wrapping

- Palletization for bulk orders

How to Select a Reliable Supplier or Manufacturer

When sourcing from countries like China, South Korea, or Turkey, evaluate the following:

6.1 Factory Strength

- Years in production

- Factory size & monthly output

- In-house R&D and testing labs

- OEM/ODM services

6.2 Export Experience

- Past export markets (e.g., Africa, Middle East, Southeast Asia, South America)

- Certifications: SGS, CE, SONCAP, SASO, CO, Form E

- Multilingual support and after-sales service

6.3 Customer Reviews and References

Ask for:

- Client references or testimonials

- Sample projects or installation photos

6.4 Logistics and Delivery Capabilities

- Fast lead times

- Custom packaging

- Support for FOB/CIF/DDU/DAP incoterms

Market Trends and Demand Forecast

As of 2025, global demand for stone-coated roofing tiles continues to grow due to:

- Increased infrastructure development in Africa and Southeast Asia

- Rising popularity of green and durable materials

- Government policies promoting resilient roofing solutions in typhoon-prone regions

Estimated growth: CAGR of 6.5% between 2023–2028

Sample Specification Sheet for Buyers

| Item | Value |

|---|---|

| Steel Type | Galvalume AZ150 |

| Thickness | 0.45 mm |

| Profile | Roman |

| Stone Chip Type | Natural Basalt, UV-resistant |

| Coating | Acrylic Resin + Top Glaze |

| Color | Customized (e.g., Terracotta) |

| Dimensions | 1340 mm x 420 mm |

| Weight | ~2.8–3.0 kg per tile |

| Lifespan | 30–50 years |

| Certifications | ISO9001, CE, SGS |

Conclusion

Choosing high-quality stone-coated roofing tiles is not just about selecting the right color or style—it’s about investing in a durable, long-lasting roofing solution that adds value to your building and ensures long-term performance.

Whether you’re a developer building residential communities or an importer serving global clients, understanding material specifications, manufacturing processes, and supplier qualifications is essential to making an informed decision.

If you’re looking for a trusted manufacturer in China with a strong export background, advanced production lines, and professional OEM/ODM service, feel free to contact us. Our factory provides high-performance stone-coated tiles that meet international standards at competitive prices.