Introduction

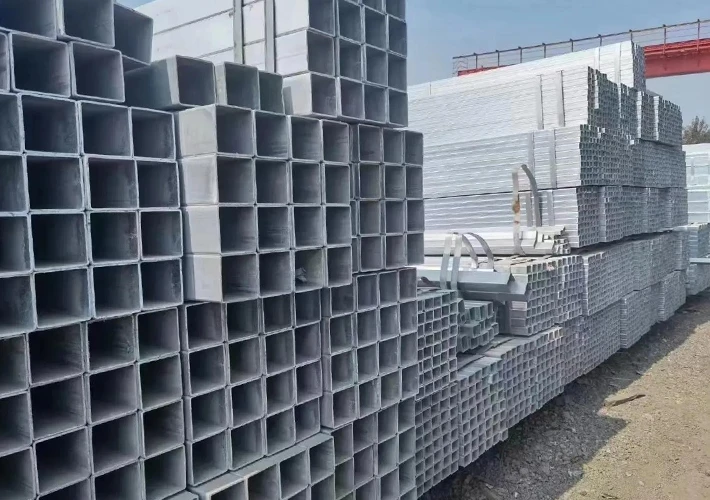

In the construction and industrial sectors, materials that offer strength, versatility, and durability are critical to success. Among various structural materials, Square Galvanized Steel Tubes have emerged as a preferred choice for engineers, architects, and manufacturers. Their unique properties—ranging from corrosion resistance to structural integrity—make them ideal for a wide array of applications. In this article, we will explore in detail why square galvanized steel tubes are ideal for construction and industrial use, analyzing their composition, benefits, and real-world applications across sectors.

What Are Square Galvanized Steel Tubes?

Square galvanized steel tubes are steel pipes formed into a square cross-section and coated with a layer of zinc through a process known as galvanization. The galvanization process can be done through:

- Hot-dip galvanizing: Immersing the steel in molten zinc.

- Pre-galvanizing: Coating the steel sheet before forming.

- Electro-galvanizing: Using electric current to bond zinc to steel.

The zinc coating acts as a protective barrier against moisture, oxygen, and other corrosive agents, significantly enhancing the lifespan of the steel.

Typical specifications:

- Shape: Square hollow section

- Material: Q195, Q235, Q345 (Chinese standards) or ASTM A500 (US standard)

- Sizes: Ranging from 15x15mm to 400x400mm

- Wall thickness: 0.8mm to 12mm

- Length: 6m or customized

Core Advantages of Square Galvanized Steel Tubes

2.1 Superior Corrosion Resistance

The most prominent advantage of galvanization is the anti-corrosion protection offered by the zinc layer. In outdoor and humid environments, bare steel tends to oxidize and corrode, leading to structural failures. Galvanized steel, however, forms a zinc oxide layer that resists corrosion, greatly enhancing its longevity.

2.2 High Strength and Load-Bearing Capacity

Square galvanized tubes offer excellent load-bearing capabilities due to their uniform shape and thickness. Their square geometry gives them an edge over round pipes in applications requiring flat surfaces for connection or pressure distribution.

They are suitable for:

- Structural frames

- Load-bearing columns

- Scaffolding and support systems

2.3 Cost-Effectiveness

Though galvanized steel tubes may have a higher initial cost than non-coated steel, the reduced maintenance and longer service life make them more cost-effective in the long run. They do not require frequent painting or treatment, saving time and labor costs.

2.4 Easy Fabrication and Welding

Galvanized square tubes are easy to cut, drill, weld, and machine, which makes them highly adaptable on construction sites. Moreover, modern galvanization processes ensure consistent coating thickness, facilitating smooth fabrication.

2.5 Aesthetic Appeal

For architectural applications, the shiny, uniform appearance of galvanized steel provides a modern, industrial look. Square tubes are often used in exposed steel structures, fences, and frames where visual appeal matters.

Applications in Construction

Square galvanized steel tubes are extensively used in both residential and commercial construction. Some common applications include:

3.1 Building Frames and Structural Support

Steel tubes serve as:

- Columns

- Beams

- Roof trusses

- Bracing members

Their high strength-to-weight ratio ensures safety without overloading the foundation.

3.2 Fencing and Gates

Galvanized square tubes are widely used in:

- Perimeter fencing

- Residential gates

- Industrial barriers

They offer durability against weather and tampering, especially in security fencing.

3.3 Scaffolding Systems

Due to their lightweight and high load resistance, square galvanized tubes are popular in temporary scaffolding structures. The tubes can be quickly assembled and disassembled, supporting rapid construction timelines.

3.4 Staircases and Handrails

Architectural steelwork such as stair rails, balustrades, and balcony frames often uses square tubes for their clean lines and structural integrity.

Applications in Industrial Fields

In addition to construction, square galvanized steel tubes are indispensable in numerous industrial sectors:

4.1 Mechanical Manufacturing

In machinery frames, storage racks, and conveyor systems, square tubes are chosen for their stability, rigidity, and ease of maintenance.

4.2 Agricultural Equipment

Galvanized steel is widely used in:

- Greenhouse frames

- Irrigation systems

- Animal pens

Its corrosion resistance is vital for exposure to water, fertilizers, and chemicals.

4.3 Energy and Utilities Infrastructure

Galvanized square tubes are applied in:

- Solar panel support frames

- Wind turbine platforms

- Utility pole reinforcements

They withstand harsh environmental conditions and maintain structural performance over time.

4.4 Transportation Equipment

From trailers to cargo carriers and railway infrastructure, square galvanized steel tubes ensure lightweight construction without compromising strength.

Environmental and Safety Advantages

5.1 Long Lifecycle and Recyclability

Galvanized steel products last 20 to 50 years, depending on the environment. At the end of their service life, the steel is 100% recyclable, contributing to green building practices and circular economies.

5.2 Fire and Pest Resistance

Unlike timber, steel does not burn or degrade due to pests, making it a safer and more durable material choice for critical structures.

5.3 Minimal Maintenance

Periodic inspection is generally sufficient. There’s no need for painting, polishing, or protective coating over time—reducing risks during facility operation and maintenance cycles.

International Standards and Certifications

To meet global construction standards, square galvanized steel tubes must adhere to strict certifications, including:

- ASTM A500 / A513 (USA)

- EN 10219 / EN 10305 (EU)

- JIS G3466 (Japan)

- GB/T 6728 (China)

Compliance ensures that the material meets the mechanical and dimensional tolerances necessary for safe construction and industrial use.

Global Market Trends

7.1 Growing Demand in Infrastructure Projects

With expanding urbanization and smart city initiatives, the demand for galvanized steel products is rising in regions such as:

- Southeast Asia

- Middle East

- Africa

- Latin America

7.2 Rising Popularity in Prefab and Modular Construction

Square galvanized tubes are well-suited to prefabricated and modular construction, which emphasizes speed, precision, and transportability. Their dimensional accuracy and low weight make logistics easier and cost-effective.

7.3 Integration with Green Building Standards

Construction industries are shifting toward sustainable materials. Galvanized steel’s low environmental impact, long lifespan, and recyclability make it compliant with:

- LEED (Leadership in Energy and Environmental Design)

- BREEAM (Building Research Establishment Environmental Assessment Method)

Comparison with Other Structural Materials

| Feature | Galvanized Steel | Mild Steel | Aluminum | Wood |

|---|---|---|---|---|

| Corrosion Resistance | Excellent | Poor | Good | Poor |

| Strength | High | Medium | Medium | Low |

| Cost | Moderate | Low | High | Low |

| Maintenance | Low | High | Medium | High |

| Environmental Durability | High | Low | Medium | Low |

| Lifespan | 20–50 years | 5–10 years | 10–20 yrs | 5–10 yrs |

Conclusion: Why Choose Square Galvanized Steel Tubes?

Square galvanized steel tubes combine strength, durability, economy, and ease of fabrication—making them an exceptional choice for both construction and industrial applications. Their versatility allows them to be used in everything from high-rise buildings and bridges to agricultural greenhouses and industrial equipment.

For B2B buyers, wholesalers, and construction firms looking to balance performance and cost, these tubes offer a highly practical solution that meets modern demands. Whether you’re building an urban infrastructure, setting up a warehouse, or designing prefabricated homes, square galvanized steel tubes deliver both structural integrity and peace of mind.

If you’re a global buyer or contractor seeking a reliable supply of square galvanized steel tubes, we are a Chinese factory with extensive production capacity and international certifications. Contact us today to receive competitive quotes and technical support.