Introduction

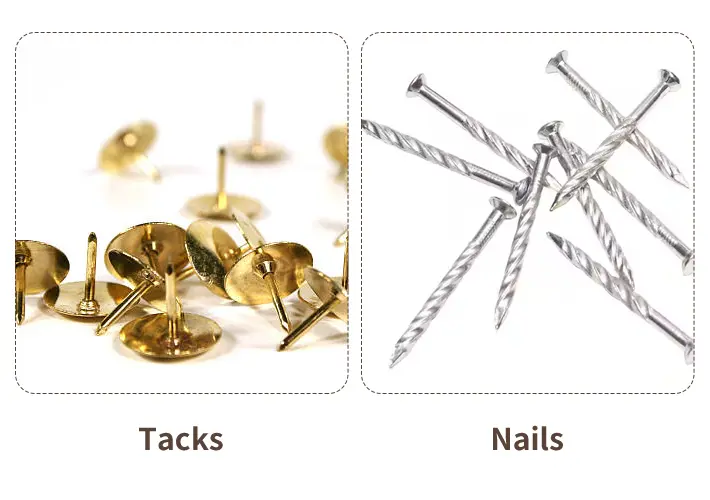

Fasteners are the unsung heroes of countless industries — from construction and furniture making to leatherwork, upholstery, and even fine art framing. Among the vast array of fasteners, tacks and nails stand out as two of the most widely used yet fundamentally different solutions for joining materials. While they may appear similar at first glance — small pieces of metal with a head and a point — their design, function, and ideal applications vary significantly.

This article provides an in-depth technical comparison of tacks and nails, focusing on their structural differences, manufacturing processes, performance characteristics, application scenarios, cost factors, and industry standards. The goal is to help industry professionals, wholesalers, and procurement specialists make informed decisions when sourcing or specifying fasteners for different projects.

Definition and Basic Differences

Before diving into details, it is essential to define the two terms clearly.

2.1 Tacks

- Definition: A short, sharp-pointed fastener with a relatively large head compared to its length, used primarily for securing fabric, leather, paper, or thin wood to a surface.

- Typical Length: 5–15 mm (0.2–0.6 inches).

- Point Style: Extremely sharp for minimal penetration force.

- Materials: Steel (often brass- or copper-plated), brass, stainless steel.

- Common Uses: Upholstery, carpet laying, shoe making, leatherwork, decorative trimming.

2.2 Nails

- Definition: A long, slender metal shaft with a pointed tip at one end and a flattened head at the other, designed to fasten pieces of wood or other materials together by driving into them.

- Typical Length: 15–150 mm (0.6–6 inches) or more.

- Point Style: Designed for deeper penetration and strong holding power.

- Materials: Low-carbon steel, stainless steel, copper, aluminum.

- Common Uses: Carpentry, framing, flooring, fencing, roofing, packaging crates.

Historical Context

3.1 Tacks

- Originated in ancient Egypt for fastening leather and fabric.

- Popularized in Europe in the 18th–19th centuries for upholstery.

- Early tacks were hand-forged with irregular shapes, later evolving into machine-cut tacks.

3.2 Nails

- Archaeological evidence shows nails were used in Roman architecture and shipbuilding over 2,000 years ago.

- Industrial production began during the 18th-century Industrial Revolution with the advent of nail-making machines.

- Modern nails benefit from high-speed wire drawing technology.

Structural & Dimensional Differences

| Feature | Tacks | Nails |

|---|---|---|

| Length | 5–15 mm | 15–150+ mm |

| Shank | Short, sometimes tapered | Long, straight, various profiles |

| Head | Wide and flat for grip & aesthetics | Smaller relative to length |

| Point | Extremely sharp for surface penetration | Sharp but optimized for deeper drive |

| Strength | Lower tensile load capacity | High tensile and shear load capacity |

Observation: The structural proportions of tacks prioritize quick anchoring in thin material without splitting the substrate, while nails prioritize deep, structural holding strength.

Manufacturing Processes

5.1 Tack Production

- Wire Selection: Typically thinner wire stock.

- Cutting: Wire cut to short lengths.

- Head Formation: Cold heading to create a wide head.

- Point Sharpening: Precision grinding to an extremely sharp point.

- Surface Finish: Plating (brass, copper, nickel) for corrosion resistance and aesthetics.

- Packaging: Often sold in small boxes for upholstery or decorative work.

5.2 Nail Production

- Wire Drawing: Heavy steel wire drawn to desired diameter.

- Cutting & Heading: Wire cut to length; head formed under high-pressure dies.

- Point Shaping: Chisel, diamond, or blunt points formed by cutting or grinding.

- Heat Treatment: Optional for hardened nails (concrete nails).

- Coating: Galvanizing, phosphate, or polymer coatings for corrosion protection.

- Bulk Packaging: Large quantities for industrial or construction use.

Mechanical Performance

6.1 Holding Strength

- Tacks: Lower holding strength due to short shank; ideal for thin materials.

- Nails: High pull-out resistance; suited for load-bearing applications.

6.2 Shear Strength

- Tacks: Minimal.

- Nails: Significant, especially with ring-shank or spiral designs.

6.3 Corrosion Resistance

- Both can be coated or plated; however, tacks used in decorative work often have brass or copper plating for visual appeal, while nails in outdoor use often require heavy galvanizing.

Application Scenarios

7.1 Tacks

- Upholstery (attaching fabric to wooden frames).

- Shoe making (attaching soles before stitching).

- Decorative trim in furniture.

- Securing carpets.

- Paper or poster mounting in notice boards.

7.2 Nails

- Wood framing in construction.

- Roofing and siding.

- Decking and fencing.

- Pallet and crate manufacturing.

- Flooring installation.

Cost Considerations

| Factor | Tacks | Nails |

|---|---|---|

| Material Usage | Less metal per piece | More metal per piece |

| Production Cost | Lower (small, less material) | Higher per unit but cheaper per kg |

| Market Price | Higher per kg (due to small size & packaging) | Lower per kg in bulk |

Example (2025 market reference, FOB China):

- Tacks: $2.5–$4.5 per 1,000 pcs (brass-plated steel).

- Nails: $800–$1,200 per metric ton for common steel nails.

Industry Standards & Specifications

Tacks

- BS 3382 (UK upholstery tacks standard).

- ASTM F1667 (covers various driven fasteners, including tacks).

Nails

- ASTM F1667 (nails, spikes, staples).

- ISO nails standards: ISO 898 for mechanical properties.

- JIS A 5508 for construction nails in Japan.

Advantages & Disadvantages

Tacks

Advantages:

- Excellent for delicate or thin materials.

- Decorative finishes available.

- Easy manual application.

Disadvantages:

- Low structural strength.

- Not suitable for heavy loads.

Nails

Advantages:

- Strong, durable fastening.

- Wide range of sizes & types.

- Suitable for structural applications.

Disadvantages:

- Can split thin materials.

- Requires more force or tools to drive.

Selection Guide for Professionals

| Requirement | Recommended Fastener |

|---|---|

| Upholstery work | Tack |

| Attaching roofing sheets | Nail (roofing type) |

| Decorative leather trim | Brass-plated tack |

| Heavy structural framing | Common nail |

| Outdoor fencing | Galvanized nail |

Conclusion

While tacks and nails both serve as fasteners, they occupy very different niches in the manufacturing and construction landscape. Tacks excel in precision, decorative, and light-duty applications, while nails dominate structural and heavy-duty fastening tasks.

For B2B procurement, understanding these distinctions is crucial. Wholesalers and contractors who specify the right fastener for the right job can ensure durability, aesthetics, and cost efficiency in their projects.