Introduction

Roofing is one of the most critical components in any building project. It directly affects weather protection, structural durability, insulation performance, and overall aesthetics. Two popular yet very different roofing options dominate many markets: corrugated metal roof sheets and flat roofing systems.

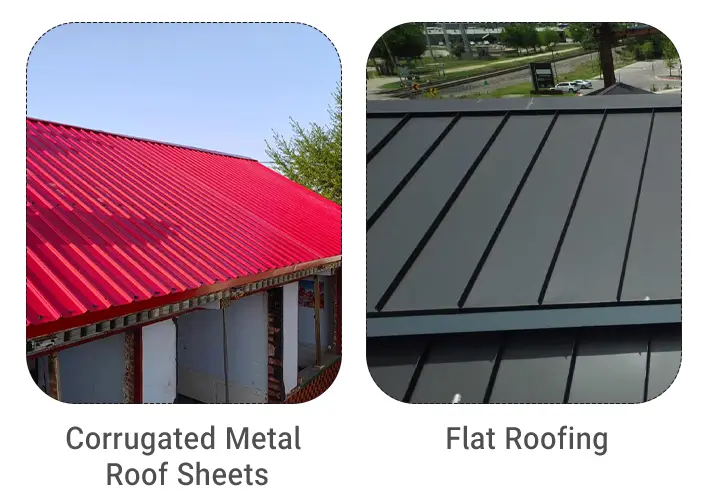

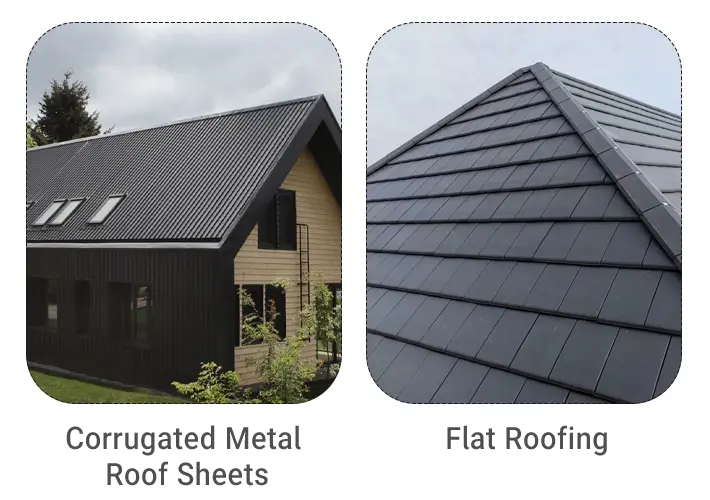

- Corrugated Metal Roof Sheets are made from galvanized steel, aluminum, or zinc-coated steel, pressed into a wave-like or ribbed profile to improve strength and water runoff.

- Flat Roofing typically uses bitumen, EPDM rubber, PVC membranes, or modified asphalt, with a nearly horizontal slope (usually 1–10 degrees) for water drainage.

Both have distinct advantages and drawbacks, depending on factors such as budget, climate, building purpose, and maintenance requirements. This article explores their pros, cons, technical differences, and market suitability in detail.

What Are Corrugated Metal Roof Sheets?

Corrugated metal roofing has been used for more than a century. The corrugation process strengthens thin metal sheets by adding wave-like ridges, allowing them to span longer distances and resist bending.

2.1 Common Materials

- Galvanized Steel – Strong, corrosion-resistant, affordable.

- Aluminum – Lightweight, rustproof, suitable for coastal areas.

- Galvalume (Aluminum-Zinc Alloy Coated Steel) – Combines strength with high corrosion resistance.

- Copper – Premium option with long life and natural patina effect.

2.2 Applications

- Industrial warehouses

- Farm buildings

- Residential houses (modern and rustic styles)

- Commercial outlets

What Is Flat Roofing?

Flat roofs are not perfectly flat — they have a minimal slope to allow water drainage. They are widely used in commercial buildings, apartment complexes, and modern-style houses.

3.1 Common Flat Roofing Materials

- EPDM (Ethylene Propylene Diene Monomer) – Synthetic rubber membrane, flexible and UV-resistant.

- TPO (Thermoplastic Polyolefin) – Heat-weldable, reflective, energy-efficient.

- PVC Membranes – Chemical-resistant, durable.

- Built-Up Roofing (BUR) – Multiple bitumen layers with gravel surfacing.

- Modified Bitumen – Asphalt-based with added polymers for flexibility.

3.2 Applications

- Large-span commercial structures

- Apartment rooftops with utility areas

- Modern architecture homes with rooftop gardens

Corrugated Metal Roof Sheets – Pros & Cons

4.1 Pros

- High Durability

- Lifespan of 40–70 years with proper maintenance.

- Resistant to wind, heavy rain, and snow loads.

- Lightweight

- Easier to install without excessive structural reinforcement.

- Fast Installation

- Large sheet coverage reduces labor time and costs.

- Low Maintenance

- Only periodic inspections and minor repairs needed.

- Excellent Water Shedding

- Corrugations naturally channel water away, reducing pooling risks.

- Fire Resistance

- Non-combustible material meets safety codes.

- Recyclable

- Environmentally friendly end-of-life disposal.

4.2 Cons

- Higher Initial Cost than Asphalt

- Although cheaper over time, upfront investment is higher.

- Noise in Rain/Hail

- May require insulation or soundproofing.

- Thermal Expansion

- Improper installation can cause warping or loose fasteners.

- Limited Flat Roof Adaptability

- Not suitable for roofs with slopes under 5 degrees.

Flat Roofing – Pros & Cons

5.1 Pros

- Cost-Effective for Large Surfaces

- Cheaper materials and simpler installation for big buildings.

- Space Utilization

- Can support rooftop HVAC units, solar panels, or gardens.

- Modern Aesthetics

- Clean, minimalist look for contemporary designs.

- Ease of Access

- Safer and easier for inspections, cleaning, and repairs.

- Lower Material Waste

- No cutting into curved profiles like corrugated sheets.

5.2 Cons

- Shorter Lifespan

- Typically 15–30 years, depending on material.

- Water Pooling Risks

- Even with slope, poor drainage can cause leaks and damage.

- Maintenance Intensive

- Requires regular inspections to avoid costly repairs.

- Thermal Stress

- Higher exposure to UV and temperature changes can lead to cracks.

- Not Ideal for Heavy Snow

- Flat roofs can collect snow, increasing load risk.

Technical Comparison Table

| Feature | Corrugated Metal Roof Sheets | Flat Roofing |

|---|---|---|

| Slope Requirement | 5°+ | 1–10° |

| Lifespan | 40–70 years | 15–30 years |

| Maintenance | Low | High |

| Water Drainage | Excellent | Moderate (risk of pooling) |

| Weight | Light (4–7 kg/m²) | Varies (20–60 kg/m²) |

| Installation Speed | Fast | Medium |

| Initial Cost | Medium–High | Low–Medium |

| Aesthetic Options | Many profiles & colors | Smooth, modern finishes |

| Fire Resistance | Excellent | Good (depends on material) |

Climate & Regional Suitability

7.1 Corrugated Metal Roof Sheets

- Best for: Tropical, coastal, and snowy regions.

- Why: Excellent drainage, corrosion-resistant coatings, strong against wind.

7.2 Flat Roofing

- Best for: Dry climates or urban areas with rooftop usage.

- Why: Can double as outdoor space; less ideal for heavy rainfall or snow.

Cost Analysis

8.1 Corrugated Metal Roof Sheets

- Material Cost: $8–$15 per m² (galvanized steel); $12–$25 per m² (aluminum or galvalume).

- Installation Cost: $5–$10 per m².

- Total Installed Cost: $13–$35 per m².

- Lifetime Cost: Lower due to long lifespan.

8.2 Flat Roofing

- Material Cost: $5–$12 per m² (EPDM/PVC); $8–$15 per m² (BUR/Modified Bitumen).

- Installation Cost: $4–$8 per m².

- Total Installed Cost: $9–$23 per m².

- Lifetime Cost: Higher due to frequent repairs/replacements.

Market Trends

Corrugated Metal Roof Demand: Rising due to green building trends, recyclability, and rural housing expansion.

Flat Roofing Demand: Growing in urban markets with commercial and high-density residential projects.

Choosing the Right Option

When deciding between corrugated metal roof sheets and flat roofing, consider:

- Climate – Heavy rain? Choose corrugated metal. Dry climate? Flat roofing works.

- Budget – Flat roofing is cheaper upfront; corrugated metal saves in the long run.

- Building Type – Industrial warehouses benefit from metal sheets; commercial complexes prefer flat roofs.

- Aesthetic Goals – Rustic or industrial look? Go corrugated. Modern minimalist? Flat roofing fits.

Conclusion

Corrugated metal roof sheets and flat roofing each have their unique advantages. Corrugated sheets excel in durability, weather resistance, and long-term savings, making them ideal for warehouses, farm buildings, and residential homes in harsh climates. Flat roofing, on the other hand, shines in urban spaces and modern architecture, providing functional rooftop space and a sleek look, but requiring more maintenance.

From a B2B perspective, distributors and importers should stock both systems to cater to different regional needs. Builders should assess climate, building function, and long-term cost efficiency before deciding.