In the world of construction, manufacturing, and industrial applications, material selection is a crucial step that determines the overall quality, durability, and efficiency of a project. Two commonly used sheet materials in various industries are steel sheets and FRP sheets. While both serve as versatile solutions for structural and decorative purposes, they differ significantly in terms of composition, performance, cost, and application scenarios.

This article provides a comprehensive comparison between steel sheets and FRP sheets, helping you make an informed decision when choosing the right material for your business or project.

Definition and Composition

1.1 Steel Sheet

Steel sheet is a flat rolled product made from carbon steel, galvanized steel, stainless steel, or other alloyed steels. It is known for its strength, rigidity, and resistance to deformation. Steel sheets can be further categorized into:

- Hot Rolled Steel Sheet

- Cold Rolled Steel Sheet

- Galvanized Steel Sheet (GI)

- Galvalume Steel Sheet (GL)

- Stainless Steel Sheet (SS)

These variations are used depending on the desired corrosion resistance, surface finish, and mechanical properties.

1.2 FRP Sheet

FRP stands for Fiber Reinforced Polymer or Fiberglass Reinforced Plastic. An FRP sheet is a composite material consisting of:

- Reinforcing Fibers: Typically glass fiber, carbon fiber, or aramid.

- Polymer Resin Matrix: Most commonly polyester, epoxy, or vinyl ester.

The fibers provide mechanical strength, while the polymer matrix holds the fibers together and protects them from environmental damage. FRP sheets are non-metallic, lightweight, and highly resistant to corrosion and chemicals.

Key Differences in Properties

| Property | Steel Sheet | FRP Sheet |

|---|---|---|

| Material Type | Metal (ferrous) | Composite (fiber + resin) |

| Density | High (7.85 g/cm³) | Low (1.5–2.0 g/cm³) |

| Strength | Very strong, rigid | High tensile strength, flexible |

| Weight | Heavy | Lightweight |

| Corrosion Resistance | Moderate to High (with coatings) | Very High |

| Thermal Conductivity | High (good heat conductor) | Low (thermal insulator) |

| Electrical Conductivity | Conductive | Non-conductive |

| Fire Resistance | High melting point (~1370°C) | Limited (can burn or deform) |

| Machinability | Requires tools, heavy equipment | Easy to cut, drill, install |

| Durability | Excellent under mechanical stress | Excellent under environmental stress |

| Recyclability | Fully recyclable | Limited recyclability |

Advantages of Steel Sheet

- Exceptional Strength: Ideal for structural load-bearing components.

- Fire Resistance: Performs well in high-temperature environments.

- Recyclability: Environmentally sustainable due to recyclability.

- Durability: Long lifespan under proper maintenance.

- Wide Availability: Easily sourced with standardized sizes.

Advantages of FRP Sheet

- Corrosion Resistance: Perfect for marine and chemical environments.

- Lightweight: Easy to transport and install, reducing labor costs.

- Low Maintenance: Does not rust, rot, or require frequent painting.

- Design Flexibility: Available in various colors, patterns, and finishes.

- Thermal and Electrical Insulation: Suitable for applications requiring non-conductivity.

Disadvantages

Steel Sheet

- Corrosion Risk: Without galvanization or coating, steel rusts quickly.

- Heavy Weight: Increases transport and installation costs.

- Conductive: Not ideal for electrical insulation.

- Expensive Processing: Requires welding, cutting, and heavy machinery.

FRP Sheet

- Flammability: Can melt or deform under high temperatures.

- Lower Structural Strength: Not suitable for heavy structural loads.

- UV Degradation: Prolonged sun exposure can lead to color fading.

- Higher Initial Cost: Depending on resin and fiber type, can be costly.

Applications Comparison

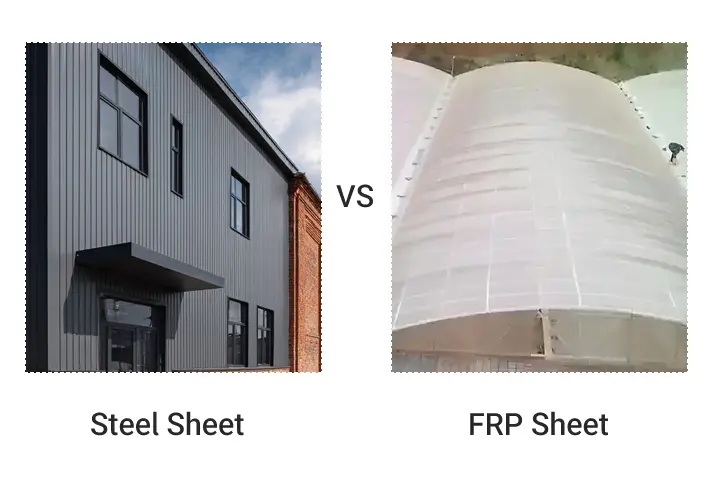

Steel Sheet Applications

- Construction (roofing, wall panels, bridges, steel frames)

- Automotive (car body panels, chassis)

- Appliances (refrigerators, washing machines)

- Shipbuilding

- Industrial machinery

- Oil & gas pipeline infrastructure

FRP Sheet Applications

- Chemical processing plants (due to corrosion resistance)

- Water treatment facilities

- Marine and coastal structures

- Decorative wall and ceiling panels

- Cooling towers

- Electrical enclosures

- Transportation (buses, trailers, lightweight applications)

Price Comparison (2024 Reference)

| Type | Price Range (USD per square meter) |

|---|---|

| Galvanized Steel Sheet | $3 – $8 |

| Stainless Steel Sheet | $10 – $25 |

| Basic FRP Sheet | $6 – $12 |

| High-performance FRP | $15 – $30 |

Note: Prices vary significantly based on thickness, surface treatment, grade, and supply chain factors. FRP has a higher cost per unit for specialized applications but may reduce long-term maintenance costs.

Maintenance and Lifespan

Steel Sheet

- Requires regular inspection and anti-corrosion treatment, especially in coastal or industrial environments.

- Lifespan: 15–50 years depending on coating and conditions.

FRP Sheet

- Requires minimal maintenance—usually just cleaning.

- Lifespan: 20–30 years in typical environments; longer in dry, indoor settings.

Environmental Impact

Steel Sheet

- High-energy consumption during production.

- Fully recyclable, making it a more circular material.

FRP Sheet

- Lower energy usage during production.

- Difficult to recycle due to composite nature, less eco-friendly at end-of-life.

- However, long life and low maintenance may offset carbon footprint.

Choosing Between Steel Sheet and FRP Sheet

| If You Need… | Choose… |

|---|---|

| High structural strength | Steel Sheet |

| Excellent corrosion resistance | FRP Sheet |

| Cost-effective large-scale building | Steel Sheet |

| Lightweight and easy installation | FRP Sheet |

| Fire resistance | Steel Sheet |

| Electrical insulation | FRP Sheet |

| High recyclability | Steel Sheet |

| Decorative and weatherproof panel | FRP Sheet |

Trends and Innovations

Steel Sheet Trends

- Increasing use of high-strength low-alloy (HSLA) steels.

- Pre-painted and coated steel for enhanced aesthetics and durability.

- Development of self-healing coatings.

FRP Sheet Trends

- Integration with nano-reinforced resins for higher strength.

- Use of bio-resins to improve sustainability.

- Wider adoption in modular buildings and prefab structures.

Conclusion

Steel sheets and FRP sheets both play vital roles in the modern industrial, construction, and infrastructure sectors. Steel stands out with its mechanical strength and cost-efficiency in structural applications, while FRP shines in environments where corrosion resistance, light weight, and insulation are priorities.

Understanding the difference between the two helps project managers, architects, and procurement officers choose the right material for their needs, optimize long-term performance, and control total lifecycle costs.

Whether you’re in manufacturing, construction, marine engineering, or energy infrastructure, the decision between steel and FRP sheets should be based on your application demands, budget, environmental conditions, and expected lifespan.

Call to Action

If you are looking for a reliable supplier of high-quality steel sheets or FRP sheets, we offer customized solutions, bulk export options, and competitive pricing. Contact our professional team to get a free quote and technical consultation today.