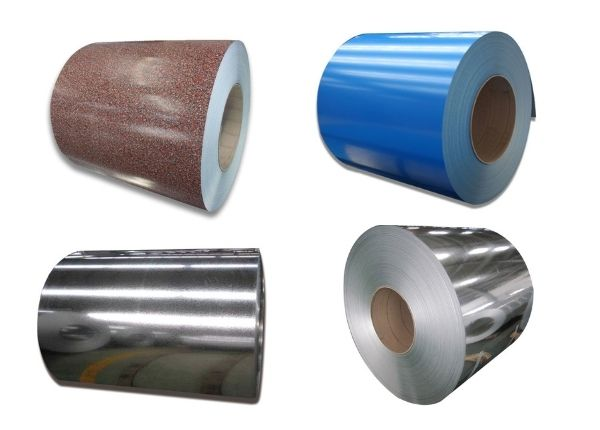

PPGI (Pre-Painted Galvanized Iron) coils play a significant role in urban construction due to their versatility, durability, and aesthetic appeal. Here’s an overview of their role and importance:

ROLE

PPGI (Pre-Painted Galvanized Iron) coils play several important roles in urban construction:

- Building Facades: PPGI coils are commonly used in urban construction for building facades. Their pre-painted surface offers a clean and uniform appearance, enhancing the aesthetic appeal of structures in urban environments. They can be customized in various colors and finishes to complement architectural designs and urban landscapes.

- Roofing: PPGI coils are widely used for roofing applications in urban areas. Their galvanized steel base provides excellent protection against corrosion, ensuring long-term durability even in harsh urban environments. The pre-painted surface adds an additional layer of protection and contributes to the overall aesthetics of buildings.

- Cladding and Siding: PPGI coils are also used for cladding and siding applications in urban construction. They provide a protective layer against weather elements, such as rain, wind, and pollution, while also offering thermal insulation properties. The pre-painted surface allows for easy customization to match the design requirements of urban buildings.

- Infrastructure Projects: PPGI coils are essential for various infrastructure projects in urban areas, including bridges, tunnels, and transportation facilities. Their corrosion resistance and durability make them suitable for structures exposed to heavy traffic, moisture, and environmental pollutants.

- Interior Applications: In addition to exterior applications, PPGI coils are used for interior applications in urban construction. They can be used for wall panels, ceilings, and partitions, providing a durable and visually appealing surface that complements the overall interior design of urban buildings.

- Modular Construction: PPGI coils are increasingly being used in modular construction techniques, where prefabricated building components are assembled off-site and then transported to urban construction sites for installation. The lightweight and easy-to-handle nature of PPGI coils make them ideal for use in modular construction projects, reducing construction time and costs.

- Sustainable Construction: PPGI coils contribute to sustainable construction practices in urban areas. The galvanized steel base material is recyclable, and the pre-painted surface can be formulated using environmentally friendly coatings. This helps reduce the environmental impact of urban construction projects and supports efforts towards sustainable development.

Overall, PPGI coils play a crucial role in urban construction by offering durability, corrosion resistance, aesthetic appeal, and sustainability, making them indispensable for building resilient and visually appealing structures in urban environments.

IMPORTANCE

PPGI (Pre-Painted Galvanized Iron) coils are of significant importance in urban construction for several reasons:

- Corrosion Resistance: PPGI coils are coated with a layer of paint or polymer on galvanized steel, making them highly resistant to corrosion. In urban environments where buildings are exposed to various weather conditions, pollutants, and moisture, corrosion resistance is crucial for maintaining the structural integrity and longevity of constructions.

- Durability: Urban constructions require materials that can withstand the rigors of heavy use and exposure to external elements. PPGI coils offer exceptional durability, ensuring that structures maintain their strength and appearance over time, even in high-traffic urban areas.

- Aesthetic Appeal: The pre-painted surface of PPGI coils provides buildings with a clean, uniform appearance. They come in a wide range of colors and finishes, allowing architects and developers to achieve their desired aesthetic goals. In urban settings where visual appeal is essential for enhancing the overall environment, PPGI coils contribute to creating attractive and vibrant cityscapes.

- Versatility: PPGI coils are versatile and can be used for various applications in urban construction, including roofing, cladding, siding, and interior finishes. Their versatility allows for flexibility in design and construction, making them suitable for a wide range of architectural styles and building types.

- Ease of Installation: PPGI coils are lightweight and easy to handle, facilitating faster and more efficient installation processes. This is particularly important in urban construction projects where time is of the essence, and minimizing disruptions to surrounding areas is crucial.

- Energy Efficiency: PPGI coatings can be formulated to reflect solar radiation, helping to reduce heat absorption and energy consumption in urban buildings. By improving the energy efficiency of structures, PPGI coils contribute to sustainability efforts and lower operating costs for building owners and occupants.

- Fire Resistance: PPGI coatings can also be designed to provide fire resistance, enhancing the safety of urban constructions. In densely populated urban areas, where the risk of fire spread is a concern, using fire-resistant materials like PPGI coils can help mitigate potential hazards and protect lives and property.

- Environmental Sustainability: Galvanized steel, the base material for PPGI coils, is recyclable, making PPGI coils an environmentally sustainable choice for urban construction. Additionally, the use of eco-friendly coatings further reduces the environmental impact of PPGI production and usage, aligning with sustainable development goals.

In summary, PPGI coils play a crucial role in urban construction by providing corrosion resistance, durability, aesthetic appeal, versatility, ease of installation, energy efficiency, fire resistance, and environmental sustainability. Their widespread use in urban developments contributes to creating resilient, visually appealing, and sustainable built environments.

PPGI coils play a crucial role in urban construction by offering corrosion resistance, durability, aesthetic appeal, ease of installation, energy efficiency, environmental sustainability, and fire resistance. Their versatility makes them suitable for a wide range of applications in urban infrastructure, contributing to the development of resilient and visually appealing urban environments.