Corrugated sheets are widely used in various industries for their versatility, durability, and cost-effectiveness. These sheets are typically made from materials such as corrugated cardboard, metal (like galvanized steel or aluminum), plastic, or fiberglass. The most common type is corrugated cardboard, which is used for packaging, shipping, and construction purposes.

Here are some key points about corrugated sheets:

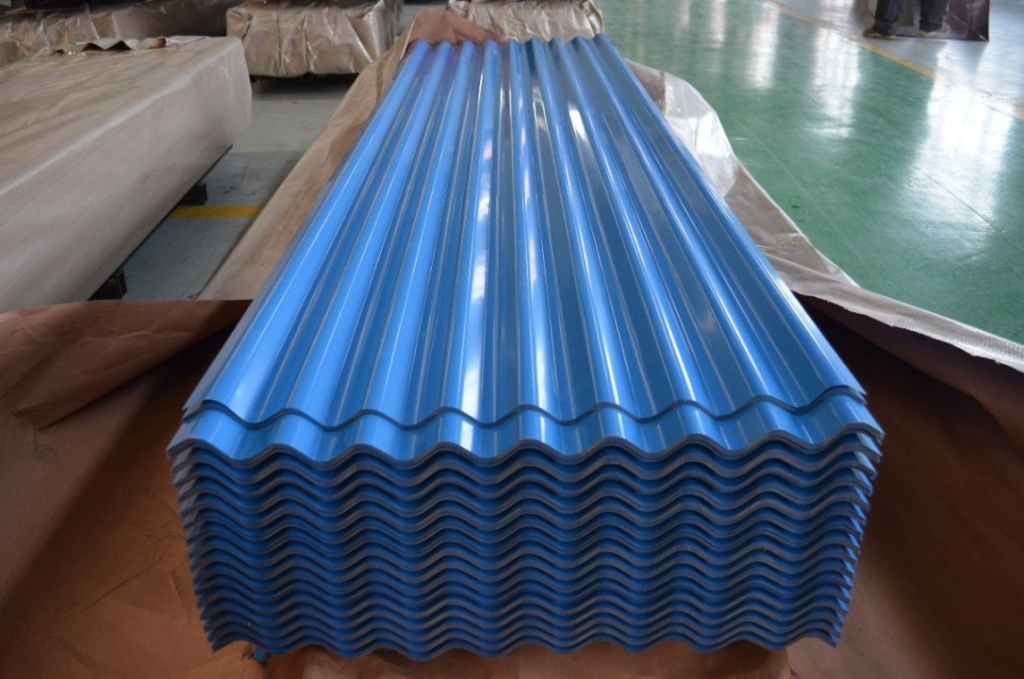

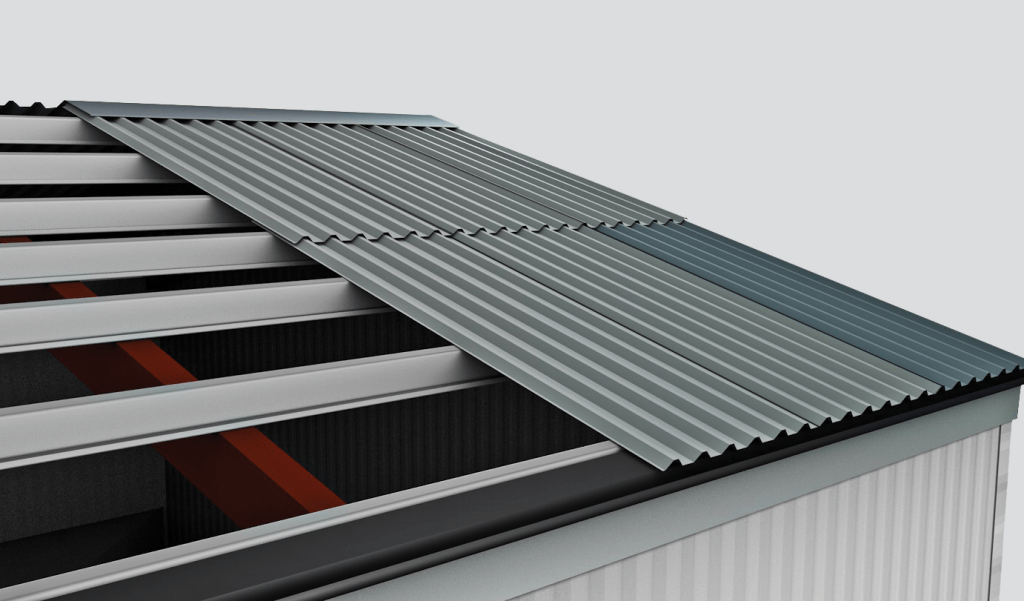

- Structure: Corrugated sheets consist of a series of parallel ridges and grooves, which give them strength and flexibility. This design provides added rigidity and support, making them suitable for various applications.

- Materials: Corrugated sheets can be made from different materials depending on the intended use. Corrugated cardboard is made from paper pulp and is lightweight, making it ideal for packaging and shipping. Metal corrugated sheets are used in construction for roofing, siding, and fencing due to their strength and weather resistance. Plastic and fiberglass corrugated sheets are used for roofing, greenhouse coverings, and signage due to their durability and transparency.

- Applications:

- Packaging and Shipping: Corrugated cardboard sheets are commonly used for packaging boxes and cartons to protect goods during transit.

- Construction: Metal corrugated sheets are popular for roofing and siding in residential, commercial, and industrial buildings.

- Agriculture: Corrugated sheets are used in agriculture for greenhouse coverings, animal shelters, and irrigation channels.

- Signage and Displays: Plastic and fiberglass corrugated sheets are used for signage, displays, and advertising due to their lightweight and durability.

- Advantages:

- Strength and Durability: Corrugated sheets are strong and resistant to bending and crushing, making them suitable for heavy-duty applications.

- Lightweight: Corrugated sheets are lightweight, making them easy to handle, transport, and install.

- Cost-Effective: Corrugated sheets are relatively inexpensive compared to other materials, making them a cost-effective choice for various applications.

- Recyclable: Corrugated cardboard sheets are recyclable and environmentally friendly, making them a sustainable packaging option.

- Customization: Corrugated sheets can be easily cut, folded, and shaped to fit specific requirements. They can also be printed or coated with various finishes for branding or decorative purposes.

Overall, corrugated sheets offer a versatile and practical solution for packaging, construction, and other applications, making them a popular choice across industries.

Here are a few practical uses for corrugated sheets:

- Packaging and Shipping: Corrugated cardboard sheets are frequently used to create shipping boxes and cartons. They provide cushioning and protection for fragile items during transit. Businesses across various industries, from e-commerce to manufacturing, rely on corrugated sheets for safe and secure packaging of their products.

- Roofing and Siding: Metal corrugated sheets are commonly used in construction for roofing and siding applications. They offer durability, weather resistance, and ease of installation, making them a popular choice for residential, commercial, and industrial buildings.

- Greenhouse Coverings: Plastic or fiberglass corrugated sheets are often utilized as coverings for greenhouses. Their lightweight nature, along with their ability to diffuse light evenly, helps create an optimal growing environment for plants while protecting them from the elements.

- Signage and Displays: Corrugated plastic sheets are widely used for outdoor signage and displays due to their weather resistance and lightweight properties. They can be easily printed on and cut into various shapes and sizes, making them suitable for advertising campaigns, event signage, and promotional displays.

- Partition Walls and Room Dividers: Corrugated cardboard sheets can be repurposed as temporary partition walls or room dividers in office spaces, event venues, or temporary shelters. They provide privacy, sound insulation, and can be easily assembled and disassembled as needed.

- Art and Craft Projects: Corrugated sheets are popular among artists and crafters for various DIY projects. They can be used to create sculptures, models, and props due to their lightweight, easy-to-cut nature, and ability to hold various finishes such as paint, glue, and decorations.

- Erosion Control: In landscaping and environmental projects, corrugated sheets can be used for erosion control. They can be installed along slopes or riverbanks to prevent soil erosion and stabilize the terrain until vegetation takes root.

The future direction of corrugated sheets is likely to involve advancements in materials, manufacturing processes, and applications to meet evolving needs and challenges. Here are some potential future directions:

- Sustainable Materials: With increasing focus on sustainability, there may be a shift towards using more eco-friendly materials for corrugated sheets. This could include further development of biodegradable or recyclable options to reduce environmental impact.

- Advanced Manufacturing Techniques: Innovations in manufacturing processes, such as 3D printing or advanced automation, could streamline production, reduce waste, and enable customization of corrugated sheets for specific applications.

- Enhanced Performance: Future corrugated sheets may be engineered to offer improved strength, durability, and weather resistance. This could involve the development of new composite materials or coatings to enhance performance under extreme conditions.

- Smart Corrugated Sheets: Integration of smart technologies, such as sensors or RFID tags, could enable corrugated sheets to provide additional functionalities such as tracking, monitoring environmental conditions, or interacting with digital systems for supply chain management.

- Expanded Applications: There may be new and expanded applications for corrugated sheets beyond traditional uses. For example, developments in lightweight and high-strength materials could lead to their adoption in automotive, aerospace, or marine industries for structural components or packaging.

- Digital Printing and Design: Advancements in digital printing technologies could enable more intricate designs, vibrant colors, and personalized branding on corrugated sheets, enhancing their aesthetic appeal and marketing value.

- Modular and Flexible Solutions: Future corrugated sheets may be designed to be more modular and flexible, allowing for easy assembly, disassembly, and reconfiguration to adapt to changing needs in various industries such as retail, events, and construction.

- Biomedical and Healthcare Applications: Corrugated sheets could find new applications in the biomedical and healthcare sectors, such as disposable medical devices, sterile packaging, or bio-safe barriers, leveraging their low-cost, lightweight, and sterile properties.

Overall, the future of corrugated sheets is likely to involve a combination of sustainability, innovation, and diversification to address emerging trends, challenges, and opportunities across industries.