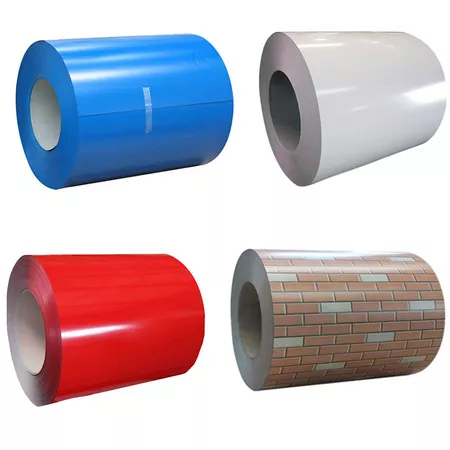

Color-coated galvanized steel coils are metal products that have undergone a coating process to enhance their durability, corrosion resistance, and aesthetic appeal. Here’s an overview of key aspects related to color-coated galvanized steel coils:

1. Base Material:

- Galvanized Steel: The base material is typically carbon steel that has been coated with a layer of zinc through a process known as galvanization. This zinc layer provides corrosion resistance to the steel.

2. Coating Process:

- Color Coating: After galvanization, the steel coils undergo a coating process where a layer of protective and decorative color coating is applied. This coating can be made of various materials, such as polyester, polyvinylidene fluoride (PVDF), or plastisol, providing different levels of durability and performance.

3. Advantages:

- Corrosion Resistance: The zinc coating provides excellent corrosion resistance, protecting the steel from rust and other environmental factors.

- Aesthetic Appeal: The color coating enhances the visual appearance of the steel, making it suitable for a wide range of applications where aesthetics are important.

- Durability: The combination of galvanization and color coating increases the overall durability and lifespan of the steel.

4. Applications:

- Construction: Used extensively in the construction industry for roofing, cladding, and siding applications.

- Appliances: Commonly used in the manufacturing of household appliances such as refrigerators and ovens.

- Automotive: Some grades are used in the automotive industry for components requiring corrosion resistance and an attractive finish.

- General Manufacturing: Used in various manufacturing processes where a combination of strength, corrosion resistance, and visual appeal is required.

5. Color Options:

- Color-coated galvanized steel coils come in a wide range of colors, allowing for customization based on the specific requirements of the application or customer preferences.

- The choice of color coating may also impact the performance characteristics, with some coatings offering enhanced resistance to UV radiation, weathering, and chemicals.

6. Quality Standards:

- Compliance with industry and international standards is crucial. Common standards include those set by organizations such as ASTM International or the International Organization for Standardization (ISO).

7. Supply Chain and Logistics:

- Logistics play a crucial role in the transportation of these coils from manufacturing facilities to end-users or construction sites. Proper packaging, handling, and transportation considerations are essential to prevent damage to the coated surface during transit.

8. Environmental Considerations:

- The coating process and materials used may have environmental implications. Manufacturers may implement eco-friendly practices and coatings that comply with environmental standards.

The logistics and transportation of imported color-coated galvanized steel coils in China involve a series of steps and considerations to ensure the efficient and timely movement of the goods. Here is a breakdown of the process:

Logistics:

- Customs Clearance:

- Initiate the customs clearance process as soon as the steel coils arrive in China.

- Ensure that all necessary import documentation, including invoices, packing lists, and certificates of origin, is accurate and complete.

- Storage and Warehousing:

- Identify suitable storage facilities for the imported coils, considering factors such as security, climate control (if necessary), and proximity to transportation hubs.

- Implement proper inventory management systems to track the quantity and condition of the coils.

- Distribution Network:

- Develop an efficient distribution network that minimizes transportation costs and ensures timely delivery to end users.

- Consider establishing regional distribution centers strategically located to serve different market segments.

- Transportation Planning:

- Collaborate with transportation providers to plan the most cost-effective and timely routes for distributing the steel coils.

- Consider factors such as road conditions, transportation regulations, and potential congestion.

- Technology Integration:

- Implement technology solutions, such as tracking systems and inventory management software, to monitor the movement of steel coils and streamline logistics operations.

- Utilize digital platforms for real-time communication with various stakeholders in the supply chain.

Transportation:

- Mode of Transport:

- Choose the most suitable mode of transportation based on factors like the volume of steel coils, distance, and urgency.

- Options include trucking for short distances, rail transport for longer distances within China, and sea freight for international shipments.

- Carrier Selection:

- Select reliable carriers with experience in handling steel products and a proven track record of safety and efficiency.

- Verify that the chosen carriers comply with all relevant transportation regulations.

- Packaging for Transit:

- Ensure that the steel coils are securely packaged for transit, considering factors such as protection from moisture, proper strapping, and cushioning materials to prevent damage.

- Customs Compliance:

- Comply with Chinese customs regulations and ensure that all required documentation is provided to customs authorities.

- Work with customs brokers to expedite the customs clearance process.

- Last-Mile Delivery:

- Coordinate with local logistics providers for the final delivery to customers.

- Consider factors such as offloading equipment, local regulations, and customer preferences.

- Risk Management:

- Implement risk management strategies to address potential challenges during transportation, such as adverse weather conditions, delays, or unforeseen events.

By carefully managing the logistics and transportation process for imported color-coated galvanized steel coils in China, businesses can optimize efficiency, reduce costs, and ensure customer satisfaction. Collaboration with experienced logistics partners and a thorough understanding of local regulations are essential components of a successful operation.