Color coated steel coils are steel sheets or strips that have been coated with a layer of paint or other protective coatings to enhance their durability and aesthetics. This process is also known as pre-painting or coil coating. The coating not only adds color but also provides corrosion resistance and improved performance.

Here are some key points about color coated steel coils:

- Base Material: Color coated steel coils are typically made from cold-rolled steel, galvanized steel, or other substrates, depending on the application and required properties.

- Coating Process: The steel coils are cleaned, pre-treated, and then coated with one or multiple layers of paint or organic coatings. The choice of coating material and process can vary based on factors like weather resistance, durability, and appearance.

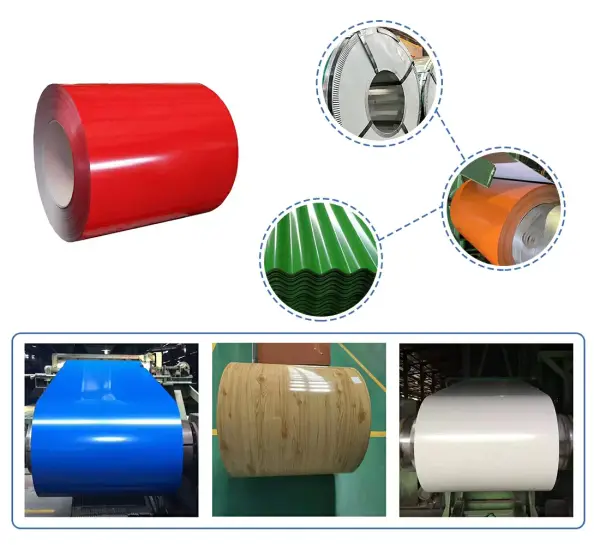

- Color Options: Color coated steel coils are available in a wide range of colors, allowing them to be used for various architectural, automotive, and industrial applications. Common coatings include polyester, silicone modified polyester, polyvinylidene fluoride (PVDF), and others.

- Applications: Color coated steel coils are used in many applications, including roofing and cladding for buildings, home appliances, automotive panels, and other products where a combination of strength, corrosion resistance, and aesthetics is required.

- Advantages: These coils offer several benefits, including enhanced appearance, protection against rust and corrosion, improved UV resistance, and the ability to customize the appearance of products.

- Durability: The durability of color coated steel coils depends on the quality of the coating and the maintenance of the product. Proper installation and maintenance can ensure the longevity of the coating.

- Environmental Considerations: Many coatings used for color coated steel are designed to be environmentally friendly, with low levels of volatile organic compounds (VOCs). Recycling steel is also an eco-friendly option.

Color coated steel coils play a significant role in construction and manufacturing, providing a durable and attractive finish to a wide range of products. They are used in a variety of industries due to their versatility and protective properties.